51 - Band Saw Upgrade, страница 19

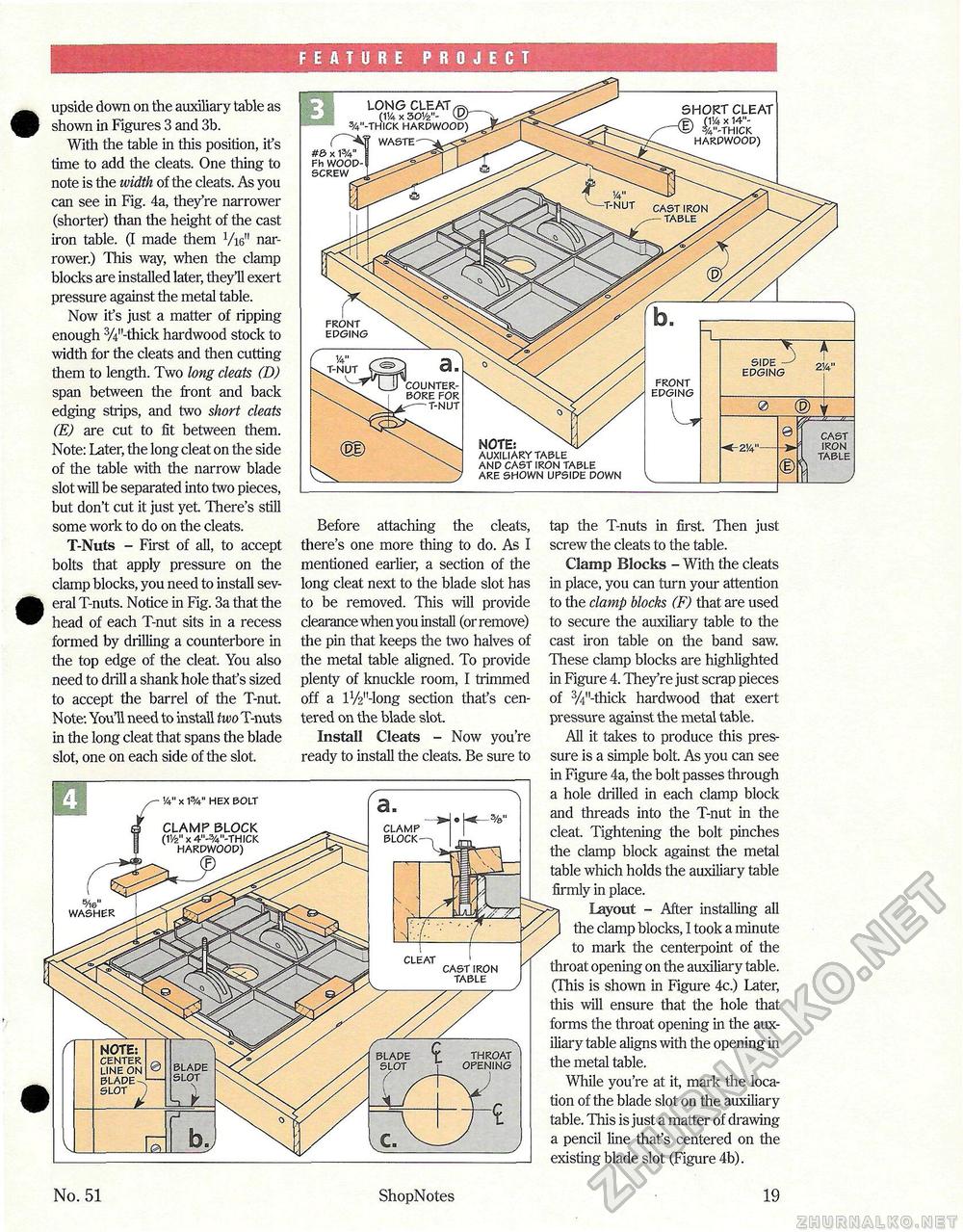

FEATURE PROJECT upside down on the auxiliary table as shown in Figures 3 and 3b. With the table in this position, ifs time to add the cleats. One thing to note is the width of the cleats. As you can see in Fig. 4a, they're narrower (shorter) than the height of the cast iron table. (I made them Vie" narrower.) This way, when the clamp blocks are installed later, they'll exert pressure against the metal table. Now ifs just a matter of ripping enough 3/4ILthick hardwood stock to width for the cleats and then cutting them to length. Two long cleats (D) span between the front and back edging strips, and two short cleats (E) are cut to fit between them. Note: Later, the long cleat on the side of the table with the narrow blade slot will be separated into two pieces, but don't cut it just yet. There's still some work to do on the cleats. T-Nuts - First of all, to accept bolts that apply pressure on the clamp blocks, you need to install several T-nuts. Notice in Fig. 3a that the head of each T-nut sits in a recess formed by drilling a counterbore in the top edge of the cleat You also need to drill a shank hole thafs sized to accept the barrel of the T-nut. Note: You'll need to install two T-nuts in the long cleat that spans the blade slot, one on each side of the slot. Before attaching the cleats, there's one more thing to do. As I mentioned earlier, a section of the long cleat next to the blade slot has to be removed. This will provide clearance when you install (or remove) the pin that keeps the two halves of the metal table aligned. To provide plenty of knuckle room, I trimmed off a lV2"-long section that's centered on the blade slot. Install Cleats - Now you're ready to install the cleats. Be sure to

tap the T-nuts in first. Then just screw the cleats to the table. Clamp Blocks - With the cleats in place, you can turn your attention to the clamp blocks (F) that are used to secure the auxiliary table to the cast iron table on the band saw. These clamp blocks are highlighted in Figure 4. They're just scrap pieces of 3/i"-thick hardwood that exert pressure against the metal table. All it takes to produce this pressure is a simple bolt. As you can see in Figure 4a, the bolt passes through a hole drilled in each clamp block and threads into the T-nut in the cleat. Tightening the bolt pinches the clamp block against the metal table which holds the auxiliary table firmly in place. Layout - After installing all the clamp blocks, I took a minute to mark the centerpoint of the throat opening on the auxiliary table. (This is shown in Figure 4c.) Later, this will ensure that the hole that forms the throat opening in the auxiliary table aligns with the opening in the metal table. While you're at it, mark the location of the blade slot on the auxiliary table. This is just a matter of drawing a pencil line thafs centered on the existing blade slot (Figure 4b). No. 51 ShopNotes 19 |

||||||||