57 - A Shop-Built Pin Router, страница 16

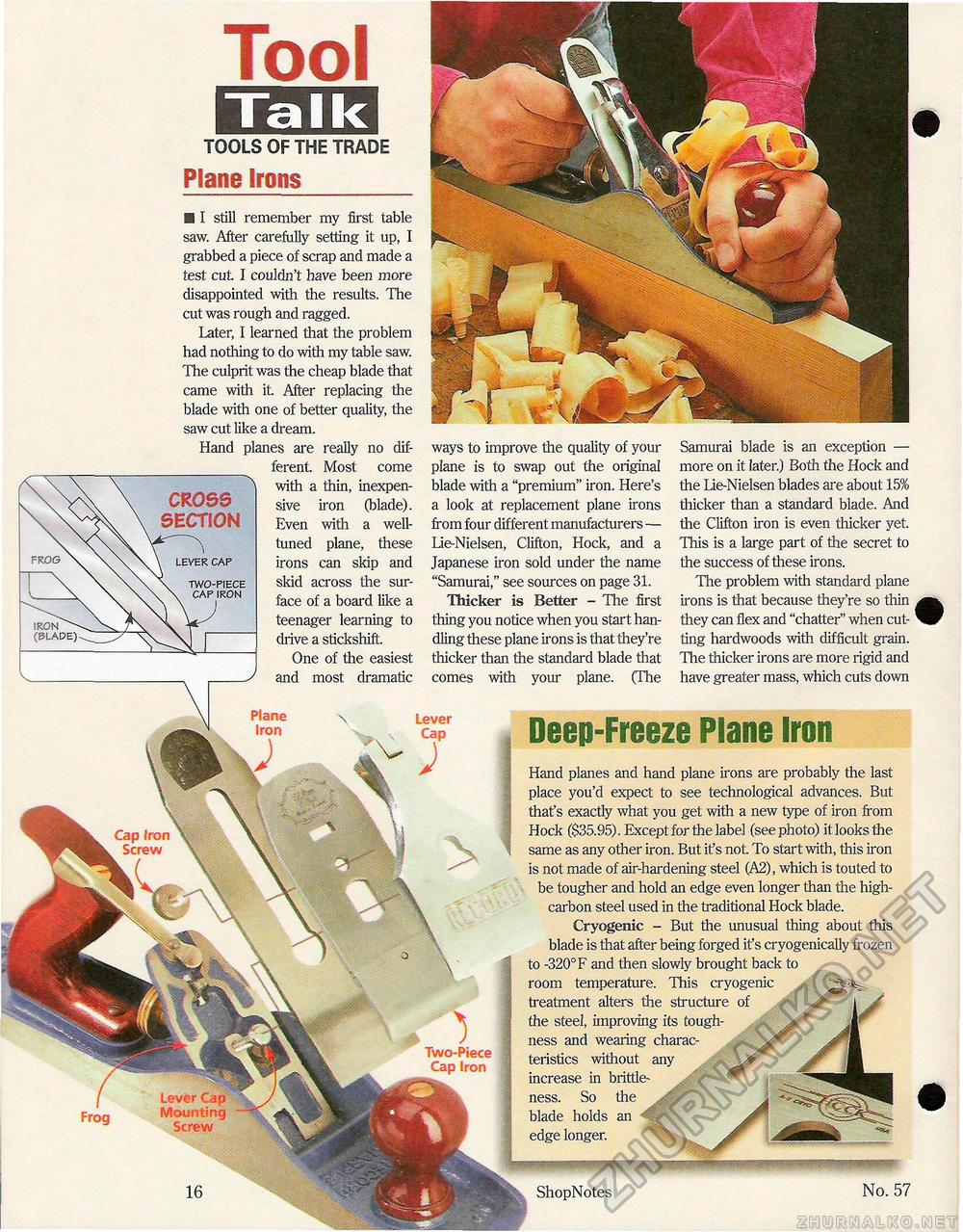

Talk TOOLS OF THE TRADE Plane Irons CROSS SECTION CAP two-piece CAP IRON ■ I still remember my first table saw. After carefully setting it up, I grabbed a piece of scrap and made a test cut. I couldn't have been more disappointed with the results. The cut was rough and ragged. Later, I learned that the problem had nothing to do with my table saw. The culprit was the cheap blade that came with it. After replacing the blade with one of better quality, the saw cut like a dream. Hand planes are really no different. Most come with a thin, inexpensive iron (blade). Even with a well-tuned plane, these irons can skip and skid across the surface of a board like a teenager learning to drive a stickshift. One of the easiest and most dramatic ways to improve the quality of your plane is to swap out the original blade with a "premium" iron. Here's a look at replacement plane irons from four different manufacturers — lie-Nielsen, Clifton, Hock, and a Japanese iron sold under the name "Samurai," see sources on page 31. Thicker is Better - The first thing you notice when you start handling these plane irons is that they're thicker than the standard blade that comes with your plane. (The Samurai blade is an exception — more on it later.) Both the Hock and the Lie-Nielsen blades are about 15% thicker than a standard blade. And the Clifton iron is even thicker yet. This is a large part of the secret to the success of these irons. The problem with standard plane irons is that because they're so thin ^^ they can flex and "chatter" when cut- ^r ting hardwoods with difficult grain. The thicker irons are more rigid and have greater mass, which cuts down Deep-Freeze Plane Iron Hand planes and hand plane irons are probably the last place you'd expect to see technological advances. But that's exactly what you get with a new type of iron from Hock ($35.95). Except for the label (see photo) it looks the same as any other iron. But it's not To start with, this iron is not made of air-hardening steel (A2), which is touted to be tougher and hold an edge even longer than the high-carbon steel used in the traditional Hock blade. Cryogenic - But the unusual thing about this blade is that after being forged if s cryogenically frozen to -320° F and then slowly brought back to room temperature. This cryogenic treatment alters the structure of Jr t jf the steel, improving its tough- jf" JjF ness and wearing charac- JF jjr® teristics without any '.^Jr' Jr ■ increase in brittle- .. blade holds an : edge longer. - ^flM 16 ShopNotes No. 57 Plane Lever Cap ) s Two-Piece \ Cap Iron | |