79 - Slant Front Tool Cart, страница 28

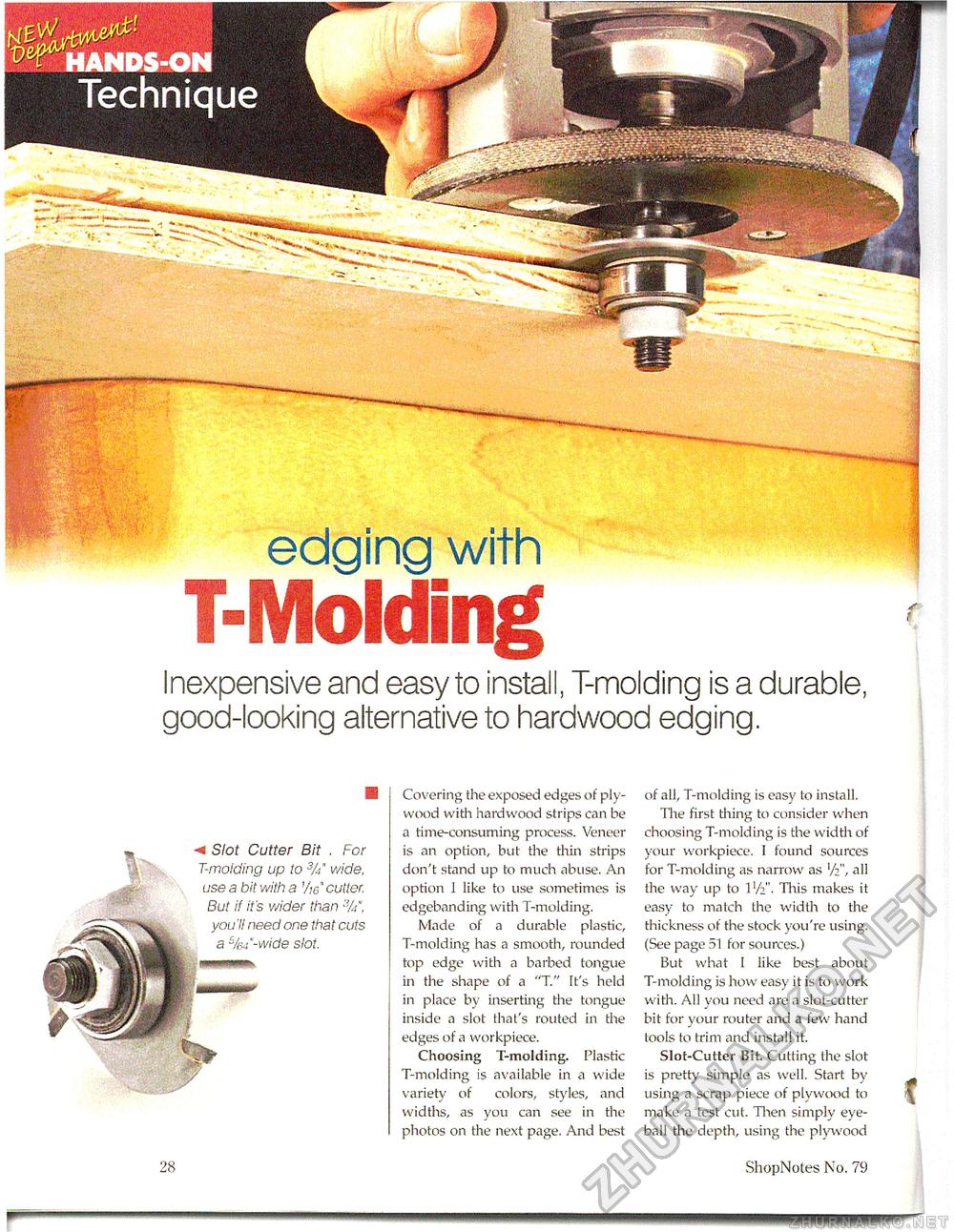

HANDS-ON Technique Inexpensive and easy to install, T-molding is a durable good-looking alternative to hardwood edging. Covering the exposed edges of plywood with hardwood strips can be a time-consuming process. Veneer is an option, but the thin strips don't stand up to much abuse. An option I like to use sometimes is edgebanding with T-molding. Made of a durable plastic, T-molding has a smooth, rounded top edge with a barbed tongue in the shape of a "T." It's held in place by inserting the tongue inside a slot that's routed in the edges of a workpiece. Choosing T-molding. Plastic T-molding is available in a wide variety of colors, styles, and widths, as you can see in the photos on the next page. And best of all, T-molding is easy to install. The first thing to consider when choosing T-molding is the width of your workpiece. I found sources for T-molding as narrow as '/a", all the way up to IV2". This makes it easy to match the width to the thickness of the stock you're using. (See page 51 for sources.) But what I like best about T-molding is how easy it is to work with. All you need are a slot-cutter bit for your router and a few hand tools to trim and install it. Slot-Cutter Bit. Cutting the slot is pretty simple as well. Start by using a scrap piece of plywood to make a test cut. Then simply eyeball the depth, using the plywood 28 ShopNotes No. 79 Slot Cutter Bit . For T-molding up to 3U" wide, use a bit with a Vw" cutter. But if it's wider than ■%", you'll need one that cuts a tyZ-wide slot. |