80 - Heirloom Tool Cabinet, страница 28

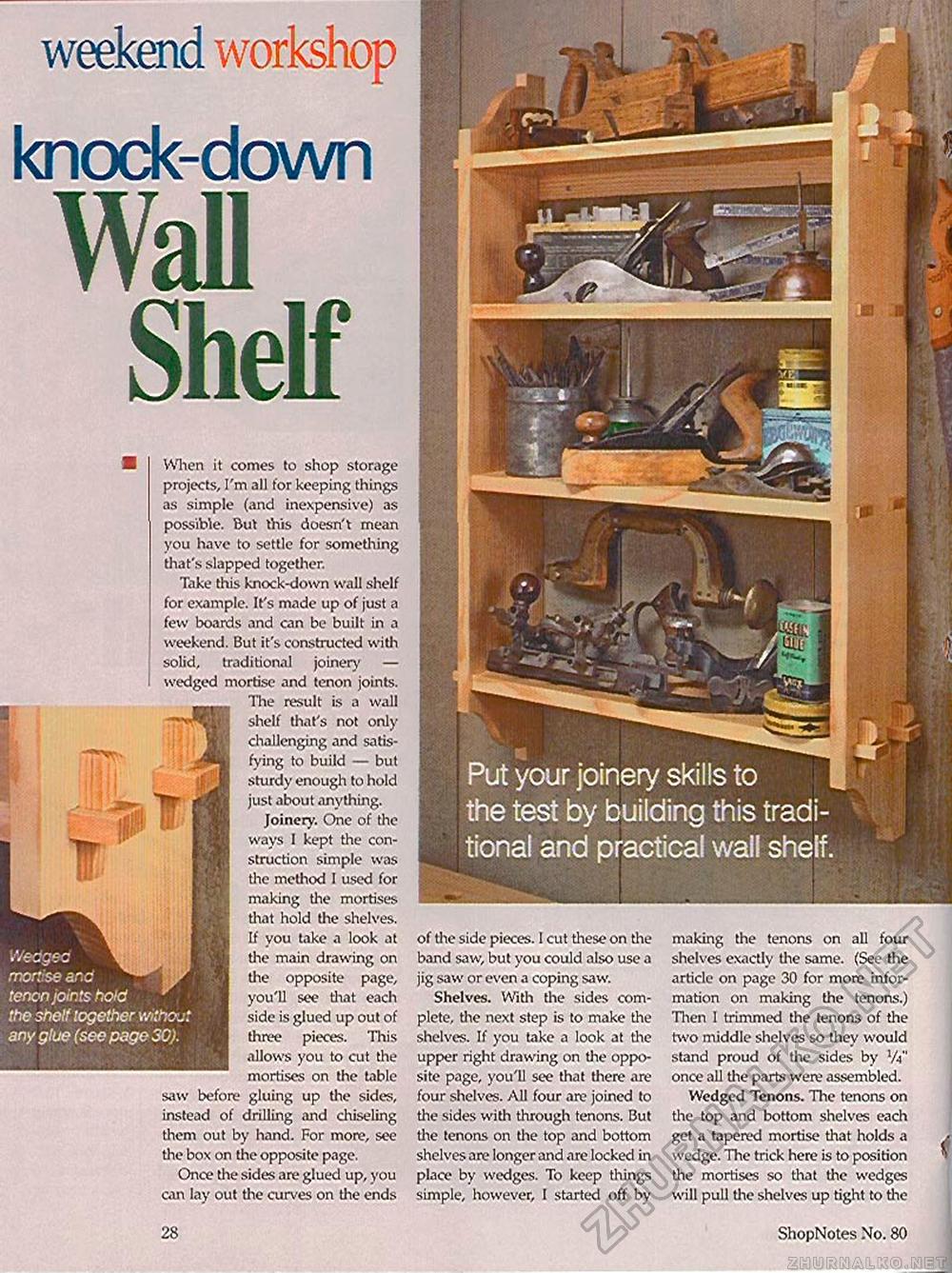

weekend workshop knock-down WaBShelfof the side pieces. I cut these on the band saw, but you could also use a jig saw or even a coping saw. Shelves. With the sides complete, the next step is to make the shelves. If you take a look at the upper right drawing on the opposite page, you'll see that there are four shelves. All four are joined to the sides with through tenons. But the tenons on the top and bottom shelves are longer and are locked in place by wedges. To keep things simple, however, I started off by making the tenons on all four shelves exactly the same. (See the article on page 30 for more information on making the tenons.) Then 1 trimmed the tenons of the two middle shelves so they would stand proud of the sides by W once all the parts were assembled. Wedged Tenons. The tenons on the top and bottom shelves each get a tapered mortise that holds a wedge. The trick here is to position the mortises so that the wedges will pull the shelves up tight to the When it comes to shop storage projects, I'm all for keeping things as simple (and inexpensive) as possible. But this doesn't mean you have to settle for something that's slapped together. Take this knock-down wall shelf for example. It's made up of just a few boards and can be built in a weekend. But it's constructed with solid, traditional joinery — wedged mortise and tenon joints. The result is a wall shelf that's not only challenging and satisfying to build — but sturdy enough to hold just about anything. Joinery. One of the ways I kept the construction simple was the method I used for making the mortises that hold the shelves. If you take a look at the main drawing on the opposite page, you'll see that each side is glued up out of three pieces. This allows you to cut the mortises on the table saw before gluing up the sides, instead of drilling and chiseling them out by hand. For more, see the box on the opposite page. Once the sides are glued up, you can lay out the curves on the ends 28 ShopNotes No. 80 |