82 - The Complete Miter Saw Workstation, страница 33

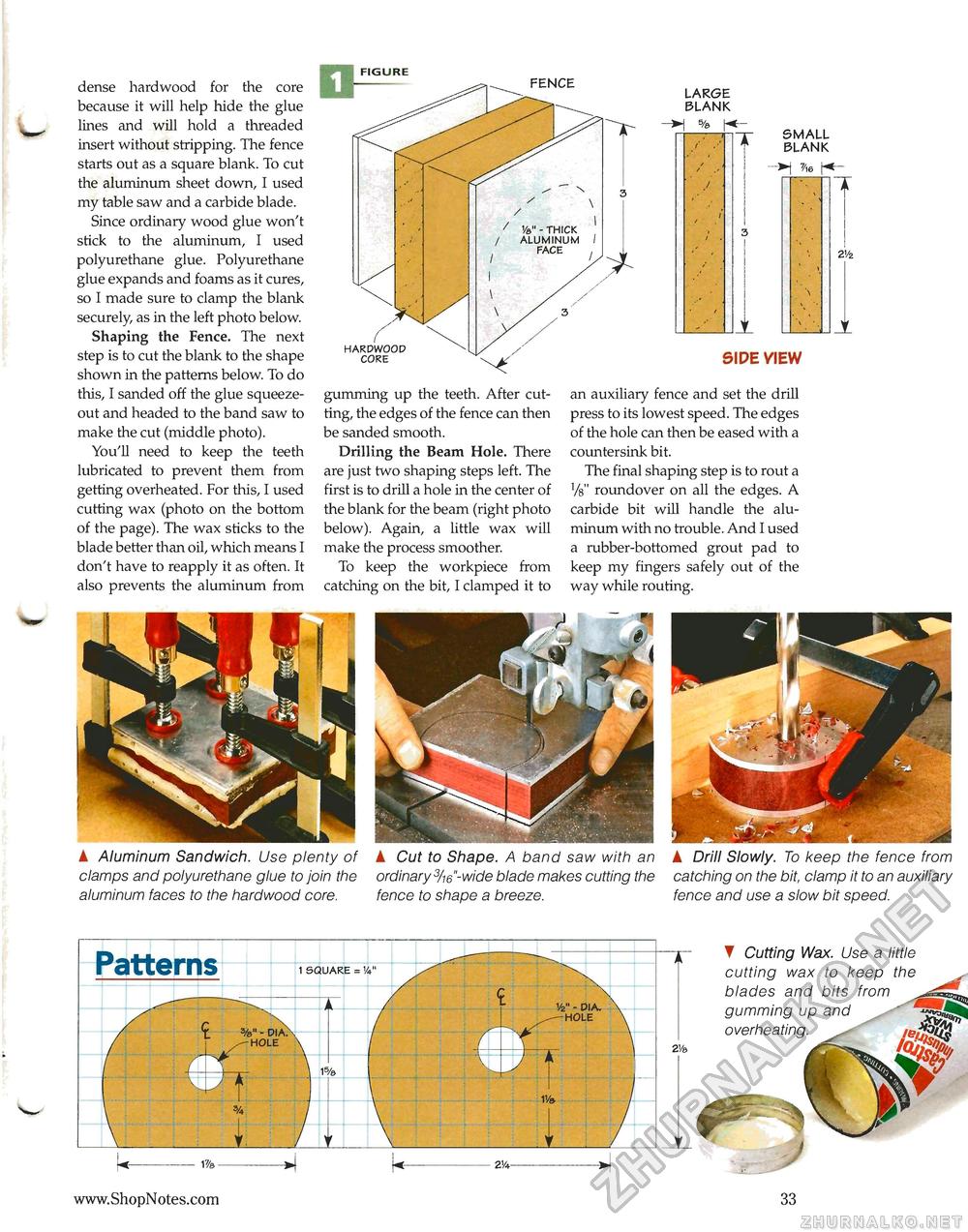

▲ Aluminum Sandwich. Use plenty of clamps and polyurethane glue to join the aluminum faces to the hardwood core. ▲ Cut to Shape. A band saw with an ordinary 3/w"-wide blade makes cutting the fence to shape a breeze. A Drill Slowly. To keep the fence from catching on the bit, clamp it to an auxiliary fence and use a slow bit speed. dense hardwood for the core because it will help hide the glue lines and will hold a threaded insert without stripping. The fence starts out as a square blank. To cut the aluminum sheet down, I used my table saw and a carbide blade. Since ordinary wood glue won't stick to the aluminum, I used polyurethane glue. Polyurethane glue expands and foams as it cures, so I made sure to clamp the blank securely, as in the left photo below. Shaping the Fence. The next step is to cut the blank to the shape shown in the patterns below. To do this, I sanded off the glue squeeze-out and headed to the band saw to make the cut (middle photo). You'll need to keep the teeth lubricated to prevent them from getting overheated. For this, I used cutting wax (photo on the bottom of the page). The wax sticks to the blade better than oil, which means I don't have to reapply it as often. It also prevents the aluminum from gamming up the teeth. After cutting, the edges of the fence can then be sanded smooth. Drilling the Beam Hole. There are just two shaping steps left. The first is to drill a hole in the center of the blank for the beam (right photo below). Again, a little wax will make the process smoother. To keep the workpiece from catching on the bit, I clamped it to an auxiliary fence and set the drill press to its lowest speed. The edges of the hole can then be eased with a countersink bit. The final shaping step is to rout a y8" roundover on all the edges. A carbide bit will handle the aluminum with no trouble. And I used a rubber-bottomed grout pad to keep my fingers safely out of the way while routing. LARGE BLANK SMALL BLANK SIDE VIEW FENCE / Va" - THICK / ALUMINUM I FACE / □ figure Patterns »" - dia. hole dia. ^HOLE ▼ Cutting Wax. Use a little cutting wax to keep the blades and bits from gumming up and overheating. 33 |