82 - The Complete Miter Saw Workstation, страница 36

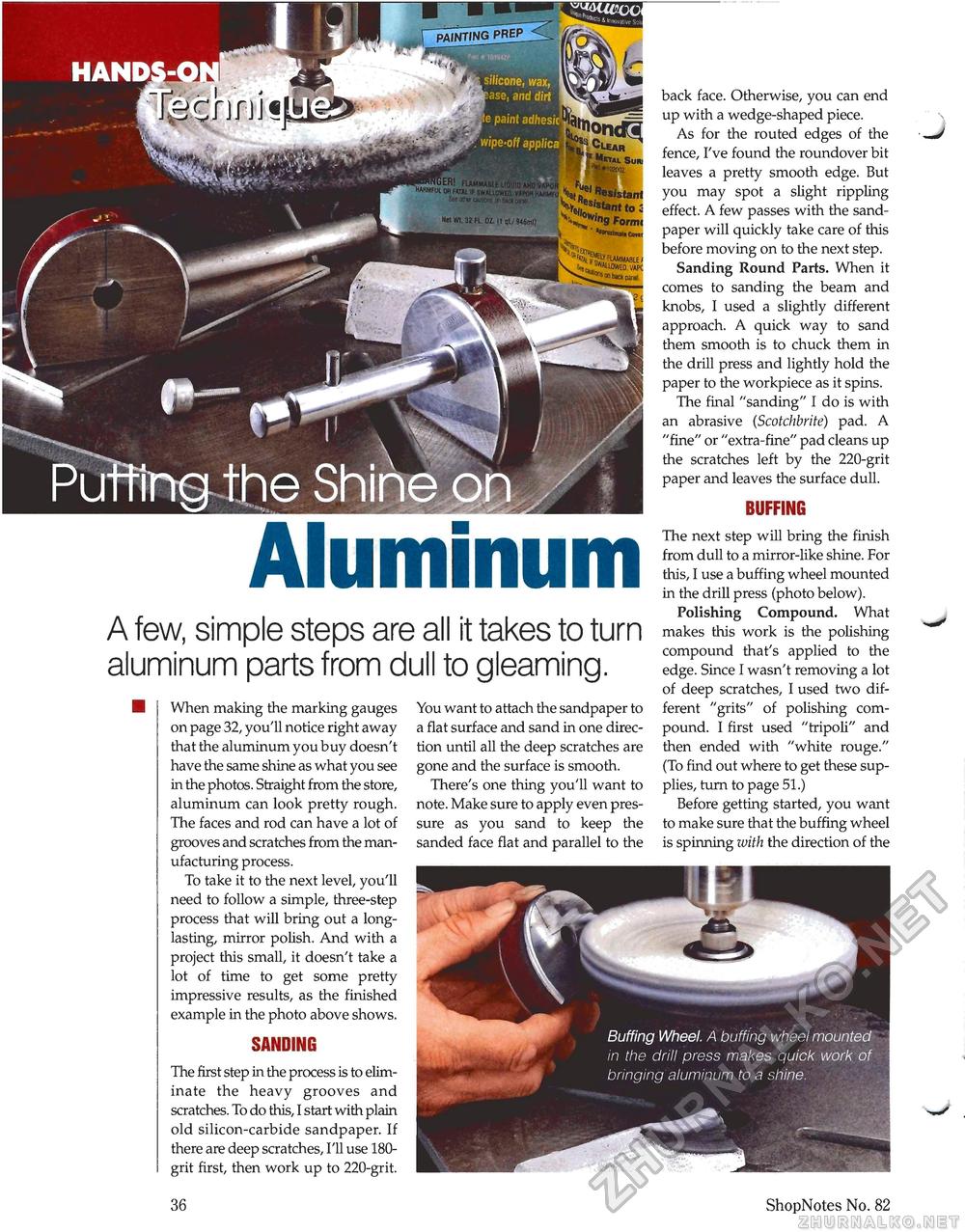

wrrmf PAINTING PREP r^cnni* Vy^stanuo;. Ss£*'«9 Form. , ^nammt Com Vw '^10*10 MPC laa oaiel Met Wt. 32 FL 0Z.I1 qt/946ml) Aluminum A few, simple steps are all it takes to turn aluminum parts from dull to gleaming. back face. Otherwise, you can end up with a wedge-shaped piece. As for the routed edges of the fence, I've found the roundover bit leaves a pretty smooth edge. But you may spot a slight rippling effect. A few passes with the sandpaper will quickly take care of this before moving on to the next step. Sanding Round Parts. When it comes to sanding the beam and knobs, I used a slightly different approach. A quick way to sand them smooth is to chuck them in the drill press and lightly hold the paper to the workpiece as it spins. The final "sanding" I do is with an abrasive (Scotchbrite) pad. A "fine" or "extra-fine" pad cleans up the scratches left by the 220-grit paper and leaves the surface dull. BUFFING The next step will bring the finish from dull to a mirror-like shine. For this, I use a buffing wheel mounted in the drill press (photo below). Polishing Compound. What ^ makes this work is the polishing compound that's applied to the edge. Since I wasn't removing a lot of deep scratches, I used two different "grits" of polishing compound. I first used "tripoli" and then ended with "white rouge." (To find out where to get these supplies, turn to page 51.) Before getting started, you want to make sure that the buffing wheel is spinning with the direction of the When making the marking gauges on page 32, you'll notice right away that the aluminum you buy doesn't have the same shine as what you see in the photos. Straight from the store, aluminum can look pretty rough. The faces and rod can have a lot of grooves and scratches from the manufacturing process. To take it to the next level, you'll need to follow a simple, three-step process that will bring out a long-lasting, mirror polish. And with a project this small, it doesn't take a lot of time to get some pretty impressive results, as the finished example in the photo above shows. SANDING The first step in the process is to eliminate the heavy grooves and scratches. To do this, I start with plain old silicon-carbide sandpaper. If there are deep scratches, I'll use 180-grit first, then work up to 220-grit. You want to attach the sandpaper to a flat surface and sand in one direction until all the deep scratches are gone and the surface is smooth. There's one thing you'll want to note. Make sure to apply even pressure as you sand to keep the sanded face flat and parallel to the 36 ShopNotes No. 82 |