82 - The Complete Miter Saw Workstation, страница 44

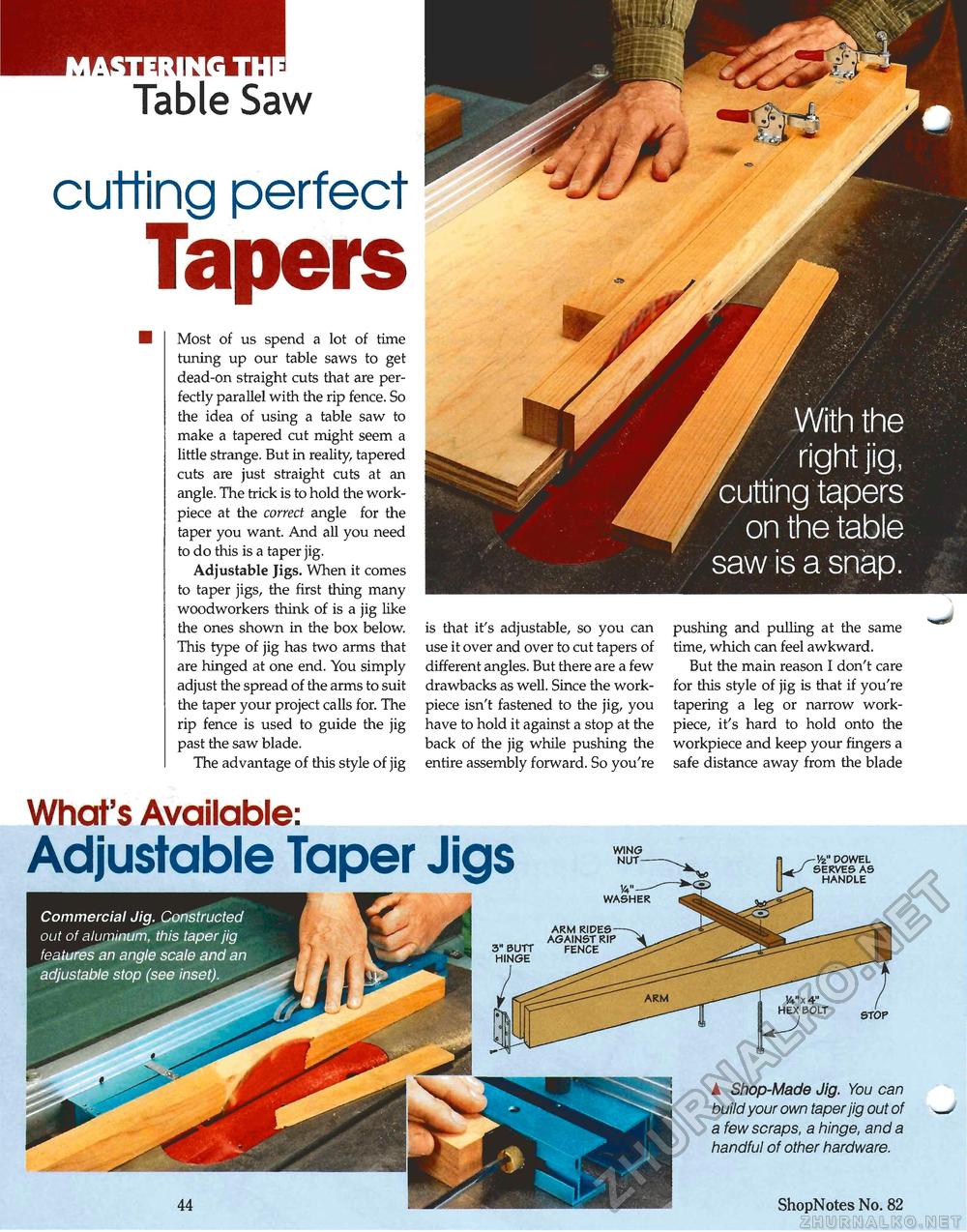

Table Saw cutting perfect TapersMost of us spend a lot of time tuning up our table saws to get dead-on straight cuts that are perfectly parallel with the rip fence. So the idea of using a table saw to make a tapered cut might seem a little strange. But in reality, tapered cuts are just straight cuts at an angle. The trick is to hold the work-piece at the correct angle for the taper you want. And all you need to do this is a taper jig. Adjustable Jigs. When it comes to taper jigs, the first thing many woodworkers think of is a jig like the ones shown in the box below. This type of jig has two arms that are hinged at one end. You simply adjust the spread of the arms to suit the taper your project calls for. The rip fence is used to guide the jig past the saw blade. The advantage of this style of jig is that it's adjustable, so you can use it over and over to cut tapers of different angles. But there are a few drawbacks as well. Since the work-piece isn't fastened to the jig, you have to hold it against a stop at the back of the jig while pushing the entire assembly forward. So you're pushing and pulling at the same time, which can feel awkward. But the main reason I don't care for this style of jig is that if you're tapering a leg or narrow work-piece, it's hard to hold onto the workpiece and keep your fingers a safe distance away from the blade What's Available: Adjustable Taper Jigs Commercial Jig. Constructed out of aluminum, this taper jig features an angle scale and an adjustable stop (see inset). 3" BUTT HINGE 44 ShopNotes No. 82 '/2" DOWEL SERVES AS HANDLE wing nut !4" WASHER ▲ Shop-Made Jig. You can build your own taper jig out of a few scraps, a hinge, and a handful of other hardware. |