82 - The Complete Miter Saw Workstation, страница 7

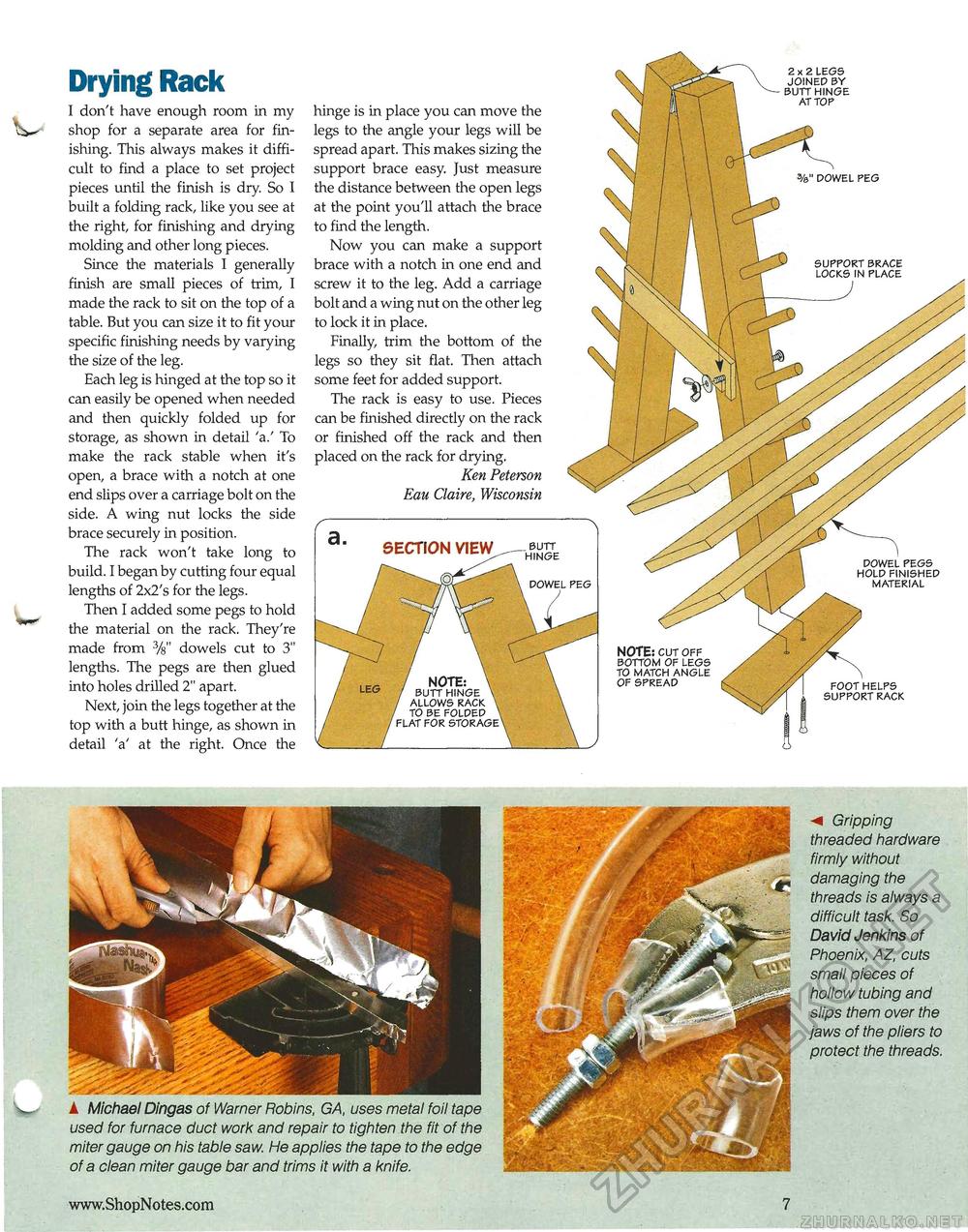

Drying Rack I don't have enough room in my shop for a separate area for finishing. This always makes it difficult to find a place to set project pieces until the finish is dry. So I built a folding rack, like you see at the right, for finishing and drying molding and other long pieces. Since the materials I generally finish are small pieces of trim, I made the rack to sit on the top of a table. But you can size it to fit your specific finishing needs by varying the size of the leg. Each leg is hinged at the top so it can easily be opened when needed and then quickly folded up for storage, as shown in detail 'a.' To make the rack stable when it's open, a brace with a notch at one end slips over a carriage bolt on the side. A wing nut locks the side brace securely in position. The rack won't take long to build. I began by cutting four equal lengths of 2x2's for the legs. Then I added some pegs to hold the material on the rack. They're made from %" dowels cut to 3" lengths. The pegs are then glued into holes drilled 2" apart. Next, join the legs together at the top with a butt hinge, as shown in detail 'a' at the right. Once the SECTION VIEW DOWEL PEG / NOTE: \ / BUTT HINGE \ / ALLOWS RACK \ ' TO BE FOLDED \ FLAT FOR STORAGE DOWEL PEGS HOLD FINISHED MATERIAL hinge is in place you can move the legs to the angle your legs will be spread apart. This makes sizing the support brace easy. Just measure the distance between the open legs at the point you'll attach the brace to find the length. Now you can make a support brace with a notch in one end and screw it to the leg. Add a carriage bolt and a wing nut on the other leg to lock it in place. Finally, trim the bottom of the legs so they sit flat. Then attach some feet for added support. The rack is easy to use. Pieces can be finished directly on the rack or finished off the rack and then placed on the rack for drying. Ken Peterson Eau Claire, Wisconsin FOOT HELPS SUPPORT RACK 2x2 LEGS JOINED BY BUTT HINGE AT TOP %" DOWEL PEG SUPPORT BRACE LOCKS IN PLACE NOTE: CUT OFF BOTTOM OF LEGS TO MATCH ANGLE OF SPREAD _ BUTT HINGE ▲ Michael Dingas of Warner Robins, GA, uses metal foil tape used for furnace duct work and repair to tighten the fit of the miter gauge on his table saw. He applies the tape to the edge of a clean miter gauge bar and trims it with a knife. ■M Gripping threaded hardware firmly without damaging the threads is always a difficult task. So David Jenkins of Phoenix, AZ, cuts small pieces of hollow tubing and slips them over the jaws of the pliers to protect the threads. 7 |