82 - The Complete Miter Saw Workstation, страница 9

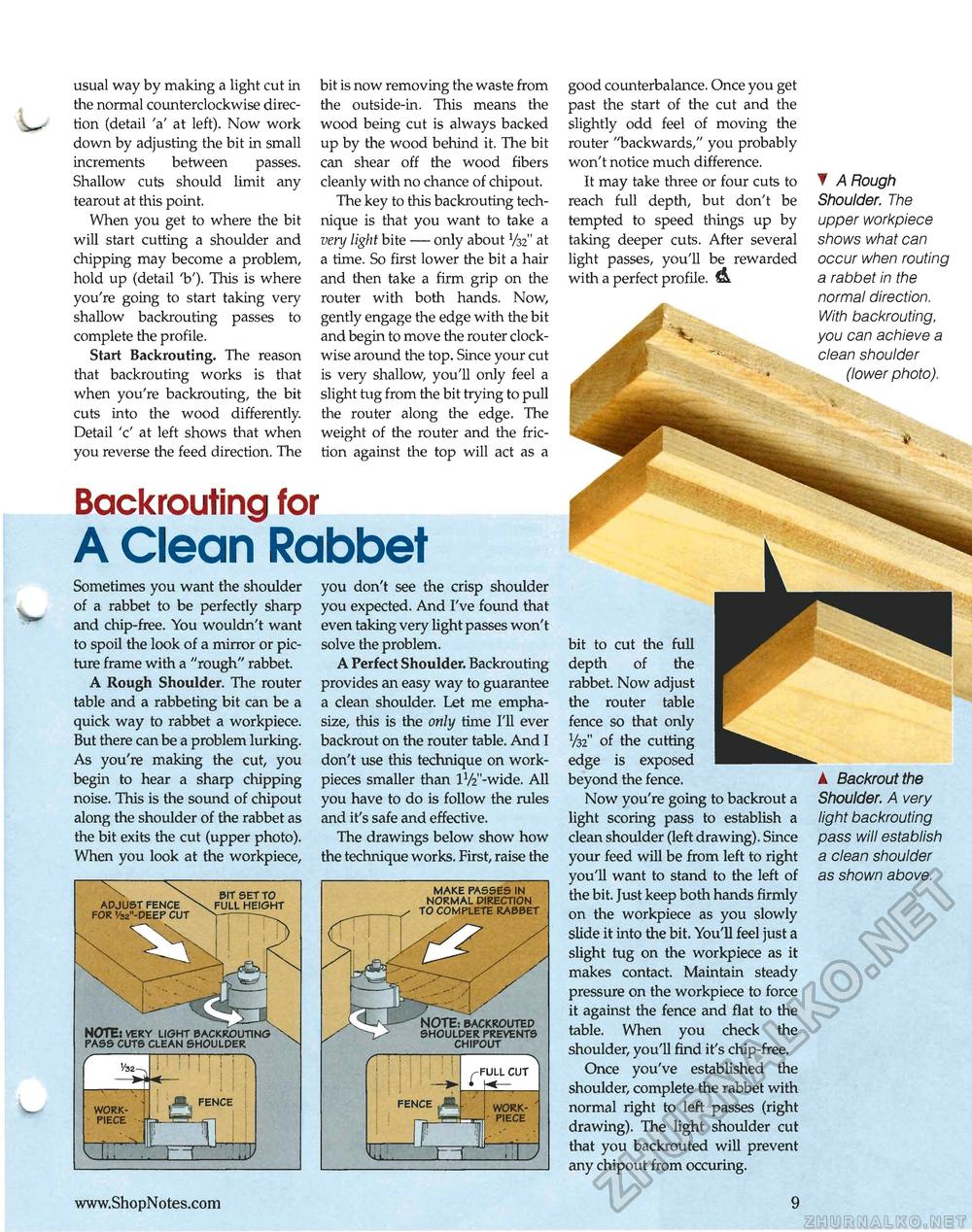

usual way by making a light cut in the normal counterclockwise direction (detail 'a' at left). Now work down by adjusting the bit in small increments between passes. Shallow cuts should limit any tearout at this point. When you get to where the bit will start cutting a shoulder and chipping may become a problem, hold up (detail V). This is where you're going to start taking very shallow backrouting passes to complete the profile. Start Backrouting. The reason that backrouting works is that when you're backrouting, the bit cuts into the wood differently. Detail 'c' at left shows that when you reverse the feed direction. The bit is now removing the waste from the outside-in. This means the wood being cut is always backed up by the wood behind it. The bit can shear off the wood fibers cleanly with no chance of chipout. The key to this backrouting technique is that you want to take a very light bite — only about V32" at a time. So first lower the bit a hair and then take a firm grip on the router with both hands. Now, gently engage the edge with the bit and begin to move the router clockwise around the top. Since your cut is very shallow, you'll only feel a slight tug from the bit trying to pull the router along the edge. The weight of the router and the friction against the top will act as a Backrouting for A Clean Rabbet Sometimes you want the shoulder of a rabbet to be perfectly sharp and chip-free. You wouldn't want to spoil the look of a mirror or picture frame with a "rough" rabbet. A Rough Shoulder. The router table and a rabbeting bit can be a quick way to rabbet a workpiece. But there can be a problem lurking. As you're making the cut, you begin to hear a sharp chipping noise. This is the sound of chipout along the shoulder of the rabbet as the bit exits the cut (upper photo). When you look at the workpiece, you don't see the crisp shoulder you expected. And I've found that even taking very light passes won't solve the problem. A Perfect Shoulder. Backrouting provides an easy way to guarantee a clean shoulder. Let me emphasize, this is the only time I'll ever backrout on the router table. And I don't use this technique on work-pieces smaller than lV2"-wide. All you have to do is follow the rules and it's safe and effective. The drawings below show how the technique works. First, raise the good counterbalance. Once you get past the start of the cut and the slightly odd feel of moving the router "backwards," you probably won't notice much difference. NOTE: VERY LIGHT BACKROUTING PASS CUTS CLEAN SHOULDER BIT SET TO ADJUST FENCE \ FULL HEIGHT FOR '/32"-DEEP CUT I I WORK-PIECE I ; ; I | j I FENCE ▼ A Rough Shoulder. The upper workpiece shows what can occur when routing a rabbet in the normal direction. With backrouting, you can achieve a clean shoulder (lower photo). bit to cut the full depth of the rabbet. Now adjust the router table fence so that only V32" of the cutting edge is exposed beyond the fence. Now you're going to backrout a light scoring pass to establish a clean shoulder (left drawing). Since your feed will be from left to right you'll want to stand to the left of the bit. Just keep both hands firmly on the workpiece as you slowly slide it into the bit. You'll feel just a slight tug on the workpiece as it makes contact. Maintain steady pressure on the workpiece to force it against the fence and flat to the table. When you check the shoulder, you'll find it's chip-free. Once you've established the shoulder, complete the rabbet with normal right to left passes (right drawing). The light shoulder cut that you backrouted will prevent any chipout from occuring. A Backrout the Shoulder. A very light backrouting pass will establish a clean shoulder as shown above. It may take three or four cuts to reach full depth, but don't be tempted to speed things up by taking deeper cuts. After several light passes, you'll be rewarded with a perfect profile. & 9 |