82 - The Complete Miter Saw Workstation, страница 6

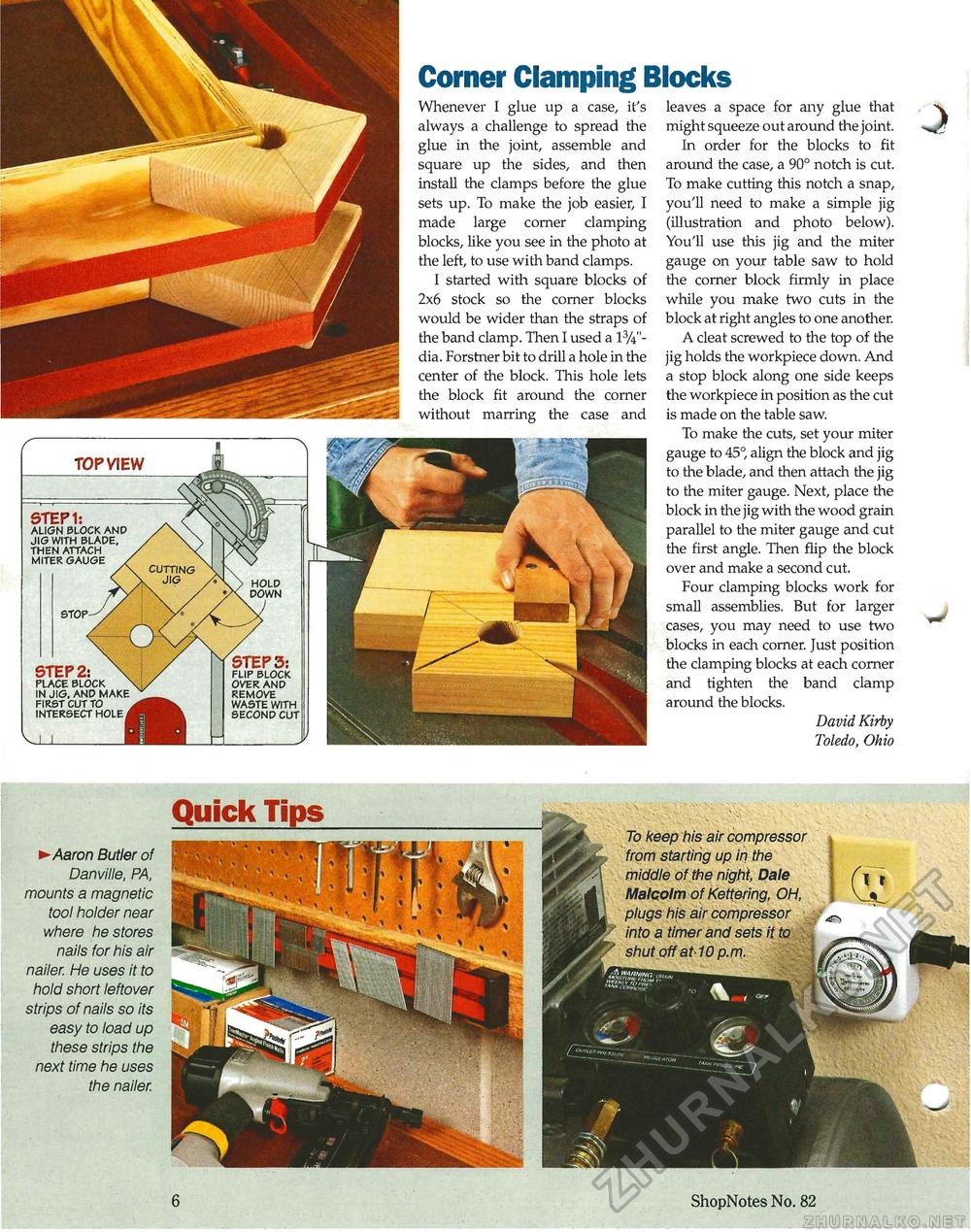

CUTTING JIG HOLD DOWN STOP Corner Clamping Blocks Whenever I glue up a case, it's always a challenge to spread the glue in the joint, assemble and square up the sides, and then install the clamps before the glue sets up. To make the job easier, I made large corner clamping blocks, like you see in the photo at the left, to use with band clamps. I started with square blocks of 2x6 stock so the corner blocks would be wider than the straps of the band clamp. Then I used a l3/4n-dia. Forstner bit to drill a hole in the center of the block. This hole lets the block fit around the corner without marring the case and leaves a space for any glue that might squeeze out around the joint. In order for the blocks to fit around the case, a 90° notch is cut. To make cutting this notch a snap, you'll need to make a simple jig (illustration and photo below). You'll use this jig and the miter gauge on your table saw to hold the corner block firmly in place while you make two cuts in the block at right angles to one another. A cleat screwed to the top of the jig holds the workpiece down. And a stop block along one side keeps the workpiece in position as the cut is made on the table saw. To make the cuts, set your miter gauge to 45°, align the block and jig to the blade, and then attach the jig to the miter gauge. Next, place the block in the jig with the wood grain parallel to the miter gauge and cut the first angle. Then flip the block over and make a second cut. Four clamping blocks work for small assemblies. But for larger cases, you may need to use two blocks in each corner. Just position the clamping blocks at each corner and tighten the band clamp around the blocks. David Kirby Toledo, Ohio f TOP VIEW STEP1: ALIGN BLOCK AND JIG WITH BLADE, THEN ATTACH MITER GAUGE STEP 2: PLACE BLOCK IN JIG, AND MAKE FIRST CUT TO INTERSECT HOLE STEP 3: FLIP BLOCK OVER AND REMOVE WASTE WITH SECOND CUT ► Aaron Butler of Danville, PA, mounts a magnetic tool holder near where he stores nails for his air nailer. He uses it to hold short leftover strips of nails so its easy to load up these strips the next time he uses the nailer. Quick Tips To keep his air compressor from starting up in the middle of.the night, Dale Malcolm of Kettering, OH, plugs his air compressor into a timer and sets it to :■ shut off at-10 p.m. 6 ShopNotes No. 82 |