84, страница 28

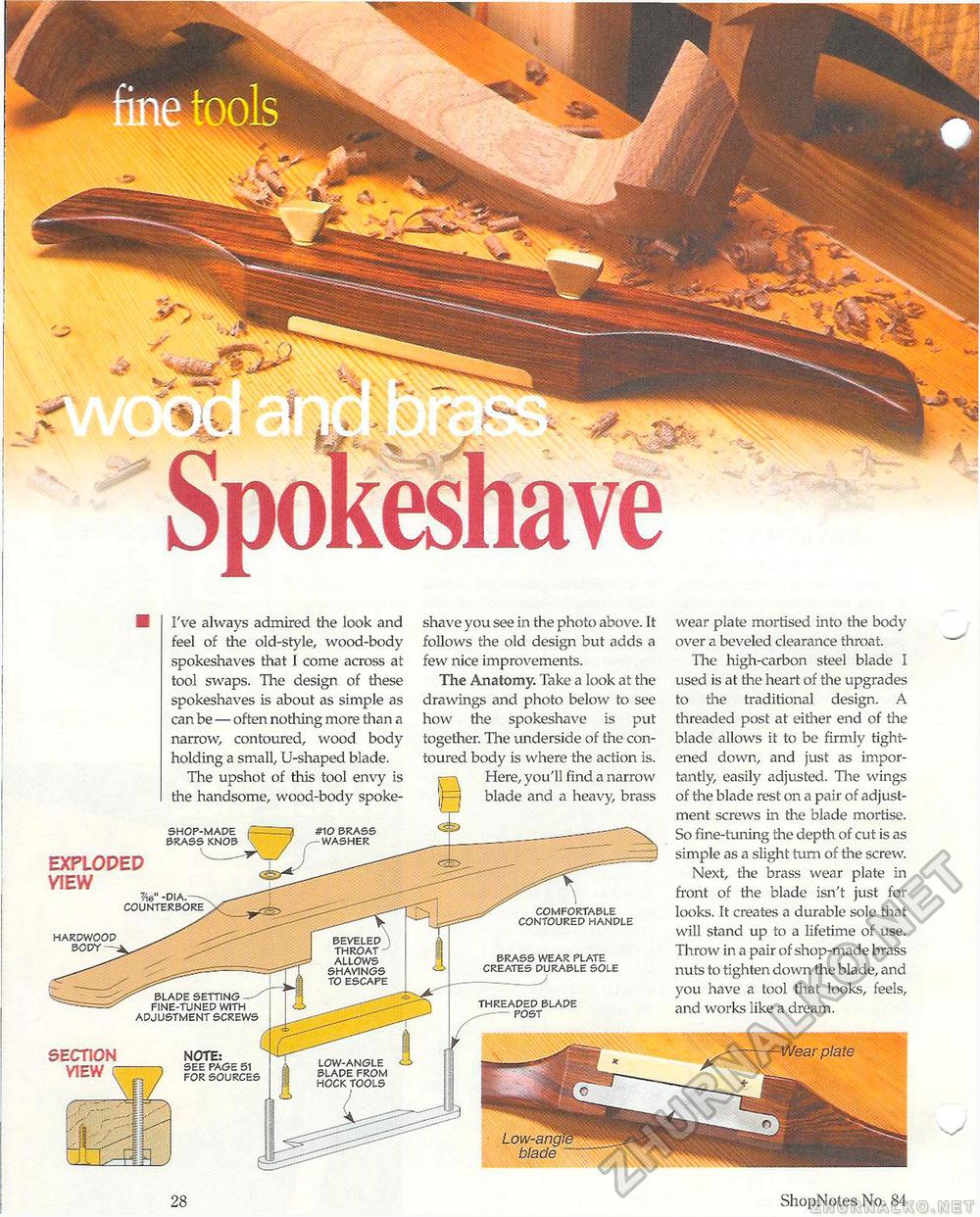

#10 BRASS -WASHER COMFORTABLE CONTOURED HANDLE Low-angl blade wear plate mortised into the body over a beveled clearance throat. The high-carbon steel blade I used is at the heart of the upgrades to the traditional design. A threaded post at either end of the blade allows it to be firmly tightened down, and just as importantly, easily adjusted. The wings of the blade rest on a pair of adjustment screws in the blade mortise. So fine-tuning the depth of cut is as simple as a slight turn of the screw. Next, the brass wear plate in front of the blade isn't just for looks. It creates a durable sole that will stand up to a lifetime of use. Throw in a pair of shop-made brass nuts to tighten down the blade, and you have a tool that looks, feels, and works like a dream. I've always admired the look and feel of the old-style, wood-body spokeshaves that 1 come across at tool swaps. The design of these spokeshaves is about as simple as can be — often nothing more than a narrow, contoured, wood body holding a small, U-shaped blade. The upshot of this tool envy is the handsome, wood-body spoke- shave you see in the photo above. It follows the old design but adds a few nice improvements. The Anatomy. Take a look at the drawings and photo below to see how the spokeshave is put together. The underside of the contoured body is where the action is. RHere, you'll find a narrow blade and a heavy, brass BRASS WEAR PLATE CREATES DURABLE SOLE THREADED BLADE - POST SHOP-MADE BRASS KNOB EXPLODED VIEW HARDWOOD BODY -D!A.—-C0UNTERB0RE BEVELED ' THROAT ALLOWS SHAVINGS TO ESCAPE BLADE SETTING — FINE-TUNED WITH ADJUSTMENT SCREWS NOTE: SEE PAGE 51 FOR SOURCES LOW-ANGLE BLADE FROM HOCK TOOLS SECTION 28 ShopNotes No. 84 |