87, страница 12

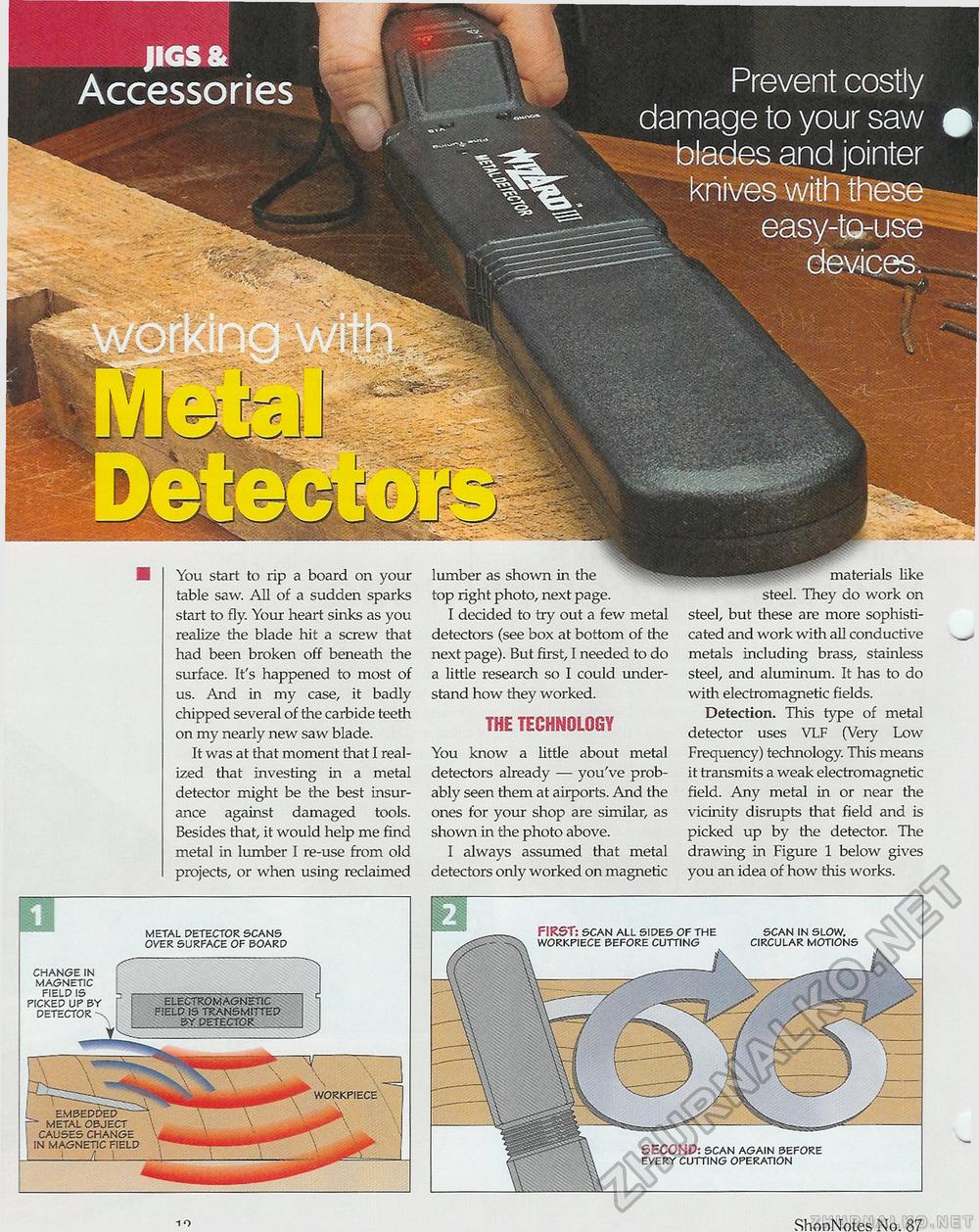

JIGS & A • Accessories steel. They do work on steel, but these are more sophisticated and work with all conductive metals including brass, stainless steel, and aluminum. It has to do with electromagnetic fields. Detection. This type of metal detector uses VLF (Very Low Frequency) technology. This means it transmits a weak electromagnetic field. Any metal in or near the vicinity disrupts that field and is picked up by the detector. The drawing in Figure 1 below gives you an idea of how this works. Prevent costly damage to your saw blades and jointer knives with these easy-tQ-use devices. You start to rip a board on your table saw. All of a sudden sparks start to fly. Your heart sinks as you realize the blade hit a screw that had been broken off beneath the surface. It's happened to most of us. And in my case, it badly chipped several of the carbide teeth on my nearly new saw blade. It was at that moment that I realized that investing in a metal detector might be the best insurance against damaged tools. Besides that, it would help me find metal in lumber I re-use from old projects, or when using reclaimed lumber as shown in the top right photo, next page. I decided to try out a few metal detectors (see box at bottom of the next page). But first, I needed to do a little research so I could understand how thev worked. THE TECHNOLOGY You know a little about metal detectors already — you've probably seen them at airports. And the ones for your shop are similar, as shown in the photo above. I always assumed that metal detectors only worked on magnetic METAL DETECTOR SCANS OVER SURFACE OF BOARD WORKPIECE CHANCE IN MAGNETIC FIELD IS PICKED UP BY DETECTOR SECOND: SCAN AGAIN BEFORE EVERY CUTTING OPERATION FIRST: SCAN ALL SIDES OF THE WORKPIECE BEFORE CUTTING SCAN IN SLOW, CIRCULAR MOTIONS 90 ShoDNotes No. 87 |