88, страница 38

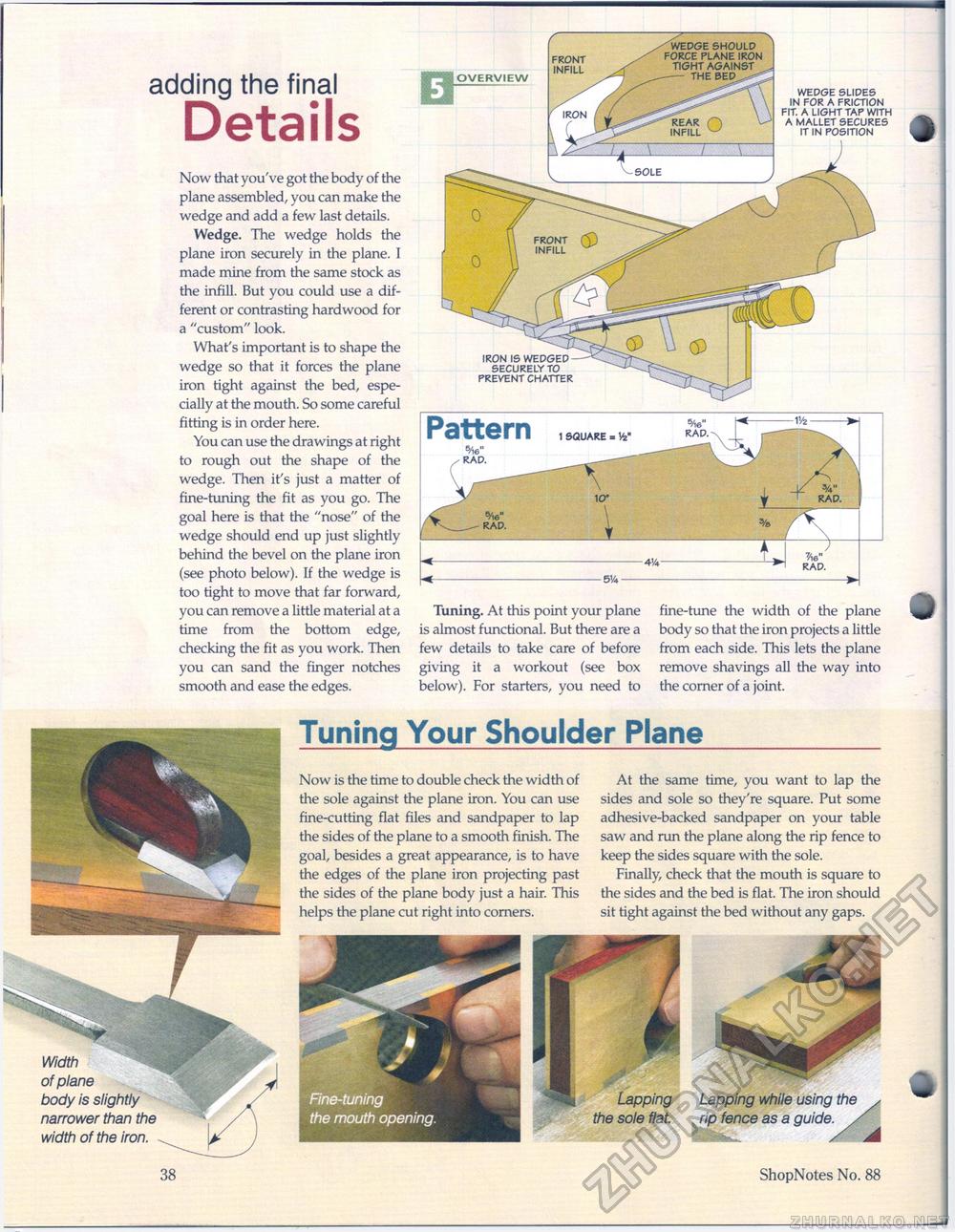

adding the final DetailsNow that you've got the body of the plane assembled, you can make the wedge and add a few last details. Wedge. The wedge holds the plane iron securely in the plane. I made mine from the same stock as the infill. But you could use a different or contrasting hardwood for a "custom" look. What's important is to shape the wedge so that it forces the plane iron tight against the bed, especially at the mouth. So some careful fitting is in order here. You can use the drawings at right to rough out the shape of the wedge. Then it's just a matter of fine-tuning the fit as you go. The goal here is that the "nose" of the wedge should end up just slightly behind the bevel on the plane iron (see photo below). If the wedge is too tight to move that far forward, you can remove a little material at a time from the bottom edge, checking the fit as you work. Then you can sand the finger notches smooth and ease the edges. Tuning. At this point your plane is almost functional. But there are a few details to take care of before giving it a workout (see box below). For starters, you need to fine-tune the width of the plane body so that the iron projects a little from each side. This lets the plane remove shavings all the way into the corner of a joint. Tuning Your Shoulder PlaneNow is the time to double check the width of the sole against the plane iron. You can use fine-cutting flat files and sandpaper to lap the sides of the plane to a smooth finish. The goal, besides a great appearance, is to have the edges of the plane iron projecting past the sides of the plane body just a hair. This helps the plane cut right into corners. At the same time, you want to lap the sides and sole so they're square. Put some adhesive-backed sandpaper on your table saw and run the plane along the rip fence to keep the sides square with the sole. Finally, check that the mouth is square to the sides and the bed is flat. The iron should sit tight against the bed without any gaps. Lapping the sole flat. Lapping while using the rip fence as a guide. IRON IS WEDGED SECURELY TO PREVENT CHATTER WEDGE SLIDES IN FOR A FRICTION FIT. A LIGHT TAP WITH A MALLET SECURES IT IN POSITION ^^ OVERVIEW f FRONT INFILL WEDGE SHOULD FORCE PLANE IRON Width of plane body is slightly narrower than the width of the iron. Fine-tuning the mouth opening. 38 ShopNotes No. 88 |