91 - Planer Stand, страница 36

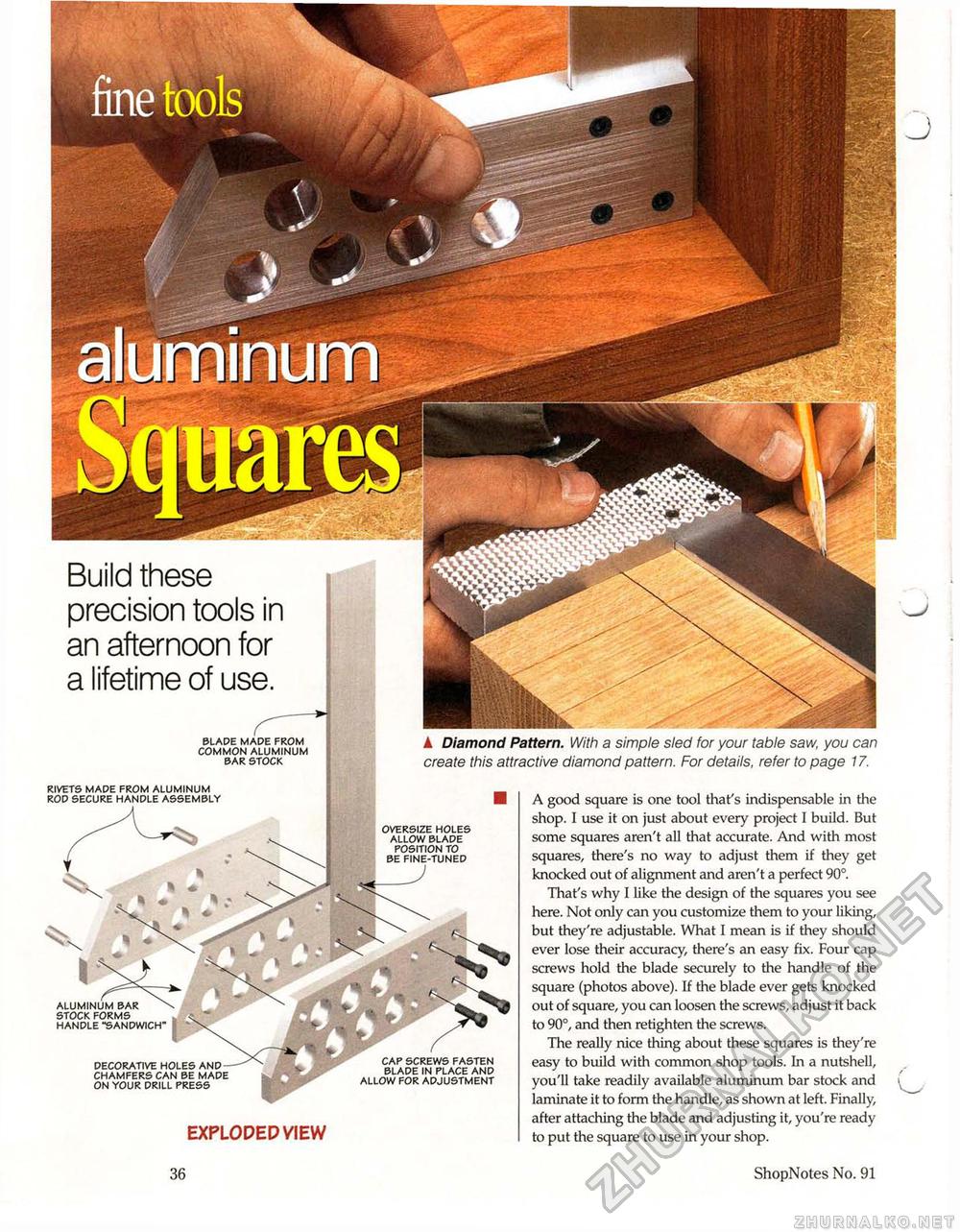

Build these precision tools in an afternoon for a lifetime of use. i BLADE MADE FROM COMMON ALUMINUM BAR STOCK RIVETS MADE FROM ALUMINUM ROD SECURE HANDLE ASSEMBLY ALUMINUM BAR STOCK FORMS HANDLE "SANDWICH DECORATIVE HOLES CHAMFERS CAN BE ON YOUR DRILL PRESS OVERSIZE HOLES ALLOW BLADE POSITION TO BE FINE-TUNED EXPLODED VIEW ▲ Diamond Pattern. With a simple sled for your table saw, you can create this attractive diamond pattern. For details, refer to page 17. A good square is one tool that's indispensable in the shop. I use it on just about every project I build. But some squares aren't all that accurate. And with most squares, there's no way to adjust them if they get knocked out of alignment and aren't a perfect 90°. That's why I like the design of the squares you see here. Not only can you customize them to your liking, but they're adjustable. What I mean is if they should ever lose their accuracy, there's an easy fix. Four cap screws hold the blade securely to the handle of the square (photos above). If the blade ever gets knocked out of square, you can loosen the screws, adjust it back to 90°, and then retighten the screws. The really nice thing about these squares is they're easy to build with common shop tools. In a nutshell, you'll take readily available aluminum bar stock and laminate it to form the handle, as shown at left. Finally, after attaching the blade and adjusting it, you're ready to put the square to use in your shop. CAP SCREWS FASTEN BLADE IN PLACE AND ALLOW FOR ADJUSTMENT 36 ShopNotes No. 91 |