92, страница 12

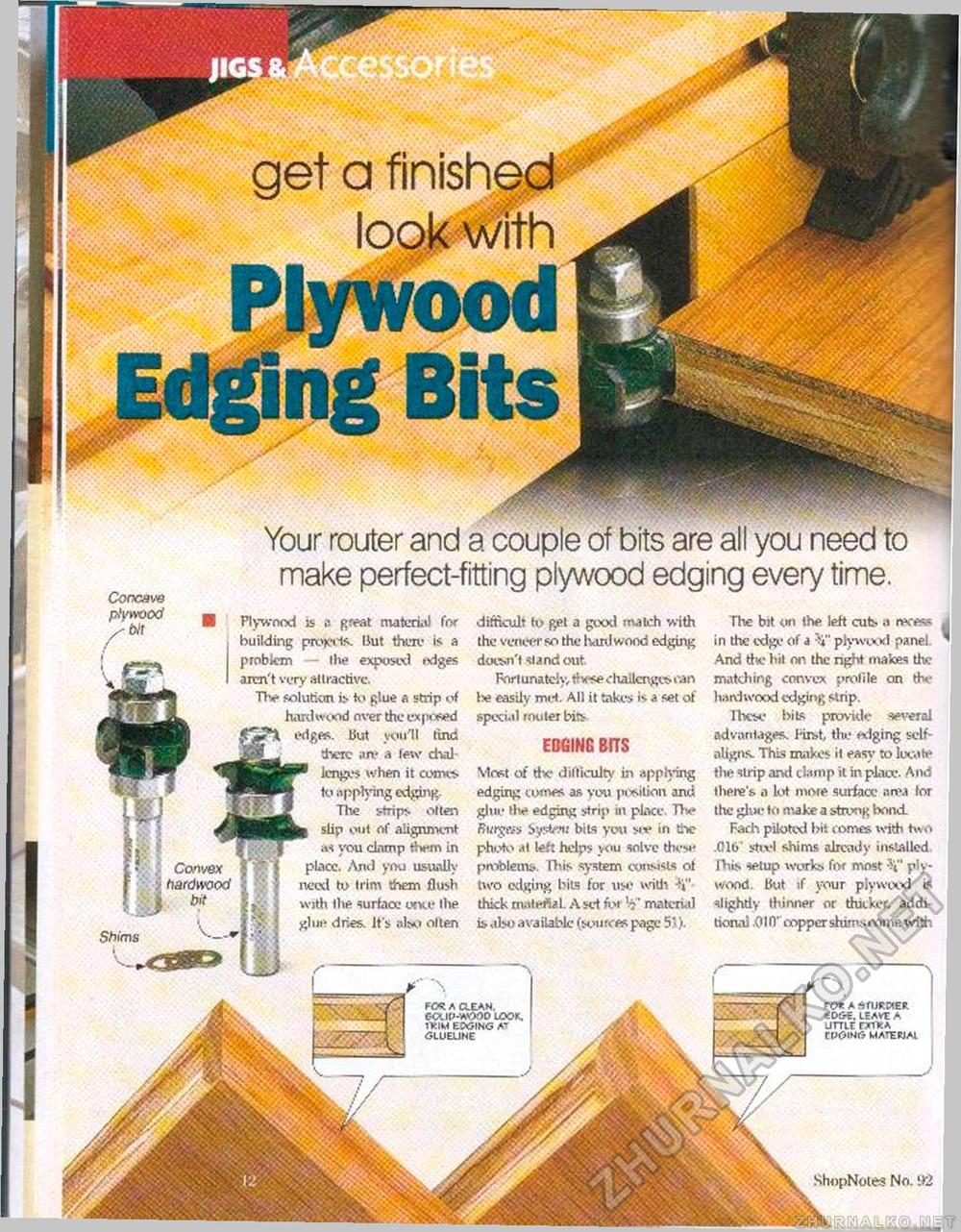

ShopNotes No. «>2 Corr-wd plywood /-Wf Your router and a couple of bits are all you need to make perfect-fitting plywood edging every time. Shims Convex <i afdwood I Plywood is a p.reat material for building project*, but there is a problem I lie exposed edges aren't very attractive. Tl* solution j> to glue a ship of hardwood over the exposed edges, but you'll tina there an? a few dial-lenges when it como to applying edging. The strips otten slip out of alignment ;is you damp ti>em in place, And you usually need to trim them flush with the surface otxc Ihe glue dries. It's also olten difficult to get a gcxxl :natch with the veneer so the lv.inl wood edging doesn't si and out. Fortunately, tt>esecliallcngte can l» easily met. All it takes is. a set of special router bits EDGING BITS Vlost of the difficulty in applying edging comes as you position and glue the edging strip in place. The Rurgea byMv bits you see in the photo at left helps you solve thc>e problems. ITiis system consists of two edging bits for use with ^i" thick matertal. A set fo> V material is also available (sources page 51). The bit on the left cuts a nvess in the edge of a :>i" plywood panel And tftc hit or. the nght makes the middling convex profile on the lianiwood edging strip. These bits provide several advantages. First, the edging self-aligns. This makes it easy to locate the strip and damp it in place. And there's a kit more surface any tor the glue to make a strong bnncL Fach piloted bit comes with two .016' stcvl shims already installed Ihis setup works for most :>i" ply-wood. but if your plywood is slightly thinner or thicker, additional .OUT copper shims come with ror A.-mjRHER tOSE. LEAST A jmr rrm>, tOOMG MA^EPJAl |