94, страница 32

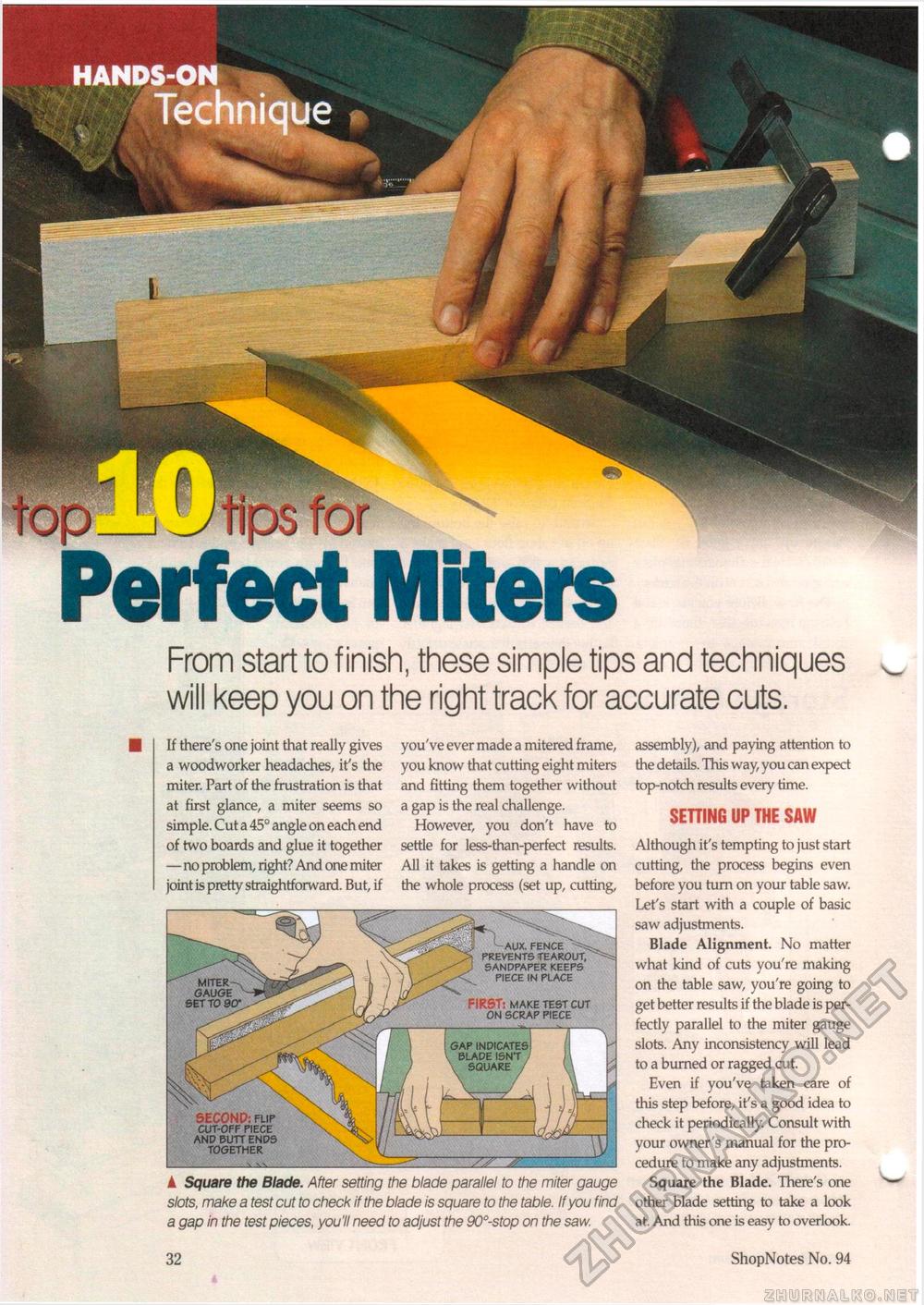

From start to finish, these simple tips and techniques will keep you on the right track for accurate cuts. If there's one joint that really gives a woodworker headaches, it's the miter. Part of the frustration is that at first glance, a miter seems so simple. Cut a 45° angle on each end of two boards and glue it together —no problem, right? And one miter joint is pretty straightforward. But, if you've ever made a mitered frame, you know that cutting eight miters and fitting them together without a gap is the real challenge. However, you don't have to settle for less-than-perfect results. All it takes is getting a handle on the whole process (set up, cutting, ▲ Square the Blade. After setting the blade parallel to the miter gauge slots, make a test cut to check if the blade is square to the table. If you find a gap in the test pieces, you'll need to adjust the 90°-stop on the saw. assembly), and paying attention to the details. This way, you can expect top-notch results every time. SETTING UP THE SAW Although it's tempting to just start cutting, the process begins even before you turn on your table saw. Let's start with a couple of basic saw adjustments. Blade Alignment. No matter what kind of cuts you're making on the table saw, you're going to get better results if the blade is perfectly parallel to the miter gauge slots. Any inconsistency will lead to a burned or ragged cut. Even if you've taken care of this step before, it's a good idea to check it periodically. Consult with your owner's manual for the procedure to make any adjustments. Square the Blade. There's one other blade setting to take a look at. And this one is easy to overlook. Perfect Miters^-AUX. FENCE ^ PREVENTS TEAROUT, SANDPAPER KEEPS PIECE IN PLACE miter --v gauge set to 90° FIRST; MAKE TEST CUT ON SCRAP PIECE gap indicates blade isn't square 3EC0NP; flip cut-off piece and butt ends together _X \\_ 32 ShopNotes No. 94 |