Woodworker's Journal 101-Projects-for-Woodworkers, страница 109

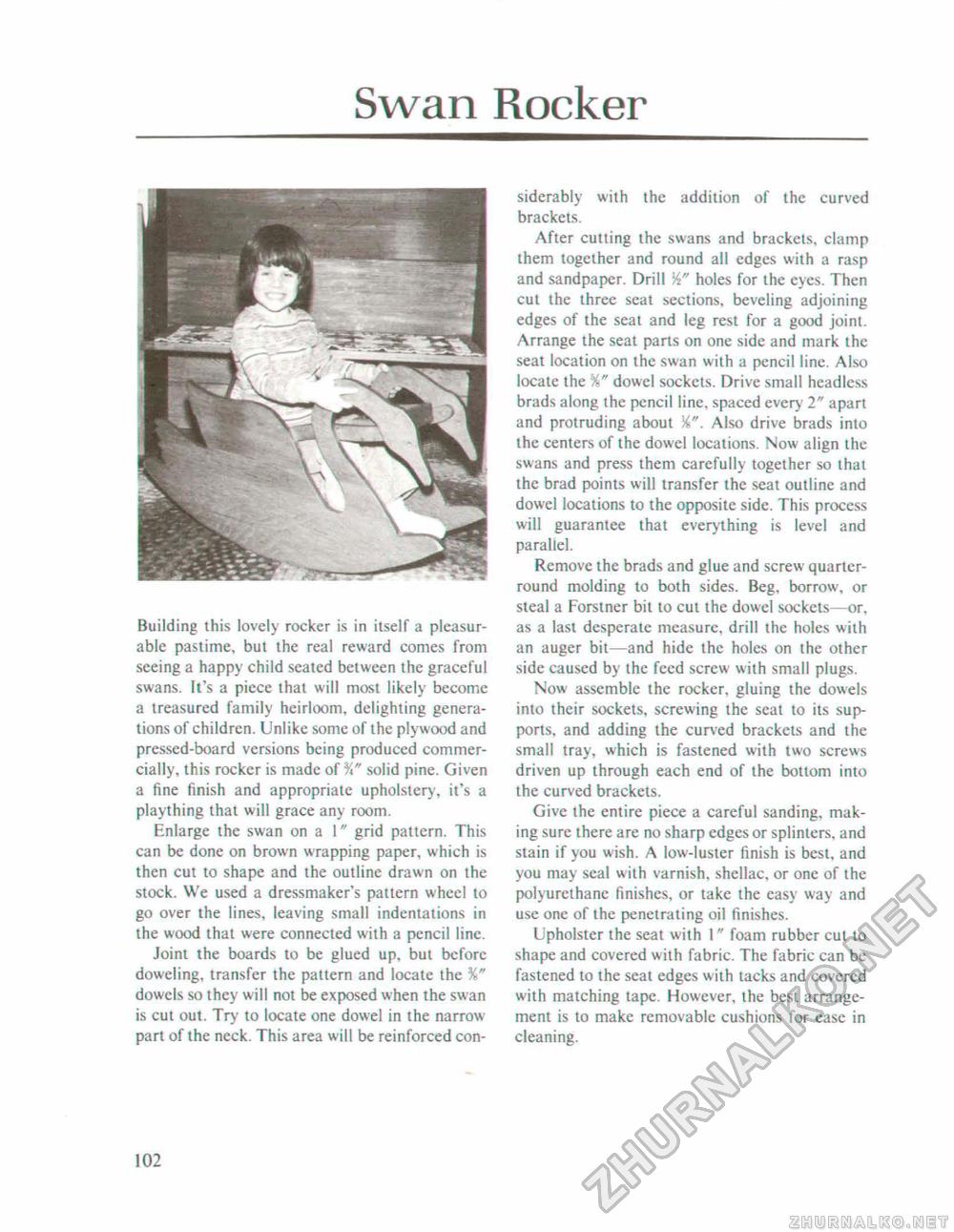

Swan RockerBuilding this lovely rocker is in itself a pleasurable pastime, but the real reward comes from seeing a happy child seated between the graceful swans. It's a piece that will most likely become a treasured family heirloom, delighting generations of children, Unlike some of the plywood and pressed-board versions being produced commercially, this rocker is made of solid pine. Given a fine finish and appropriate upholstery, it's a plaything that will grace any room. Enlarge the swan on a 1" grid pattern. This can be done on brown wrapping paper, which is then cut to shape and the outline drawn on the stock. We used a dressmaker's pattern wheel to go over the lines, leaving small indentations in the wood that were connected with a pencil line. Joint the boards to be glued up, but before doweling, transfer the pattern and locate the %" dowels so they will not be exposed when the swan is cut out. Try to locate one dowel in the narrow part of the neck. This area will be reinforced con siderably with the addition of the curved brackets. After cutting the swans and brackets, clamp them together and round all edges with a rasp and sandpaper. Drill W holes for the eyes. Then cut the three seat sections, beveling adjoining edges of the seat and leg rest for a good joint. Arrange the seat parts on one side and mark the seat location on the swan with a pencil line. Also locate the %" dowel sockets. Drive small headless brads along the pencil line, spaced every 2" apart and protruding about %". Also drive brads into the centers of the dowel locations. Now align the swans and press them carefully together so that the brad points will transfer the seat outline and dowel locations to the opposite side. This process will guarantee that everything is level and parallel. Remove the brads and glue and screw quarter-round molding to both sides. Beg, borrow, or steal a Forstner bit to cut the dowel sockets—or. as a last desperate measure, drill the holes with an auger bit—and hide the holes on the other side caused by the feed screw with small plugs. Now assemble the rocker, gluing the dowels into their sockets, screwing the scat to its supports. and adding the curved brackets and the small tray, which is fastened with two screws driven up through each end of the bottom into the curved brackets. Give the entire piece a careful sanding, making sure there are no sharp edges or splinters, and stain if you wish. A low-luster finish is best, and you may seal with varnish, shellac, or one of the polyurethane finishes, or take the easy way and use one of the penetrating oil finishes. Upholster the seat with 1" foam rubber cut to shape and covered with fabric. The fabric can be fastened to the seat edges with tacks and covered with matching tape, However, the best arrangement is to make removable cushions for ease in cleaning. 102 |