Woodworker's Journal 1980-4-5, страница 14

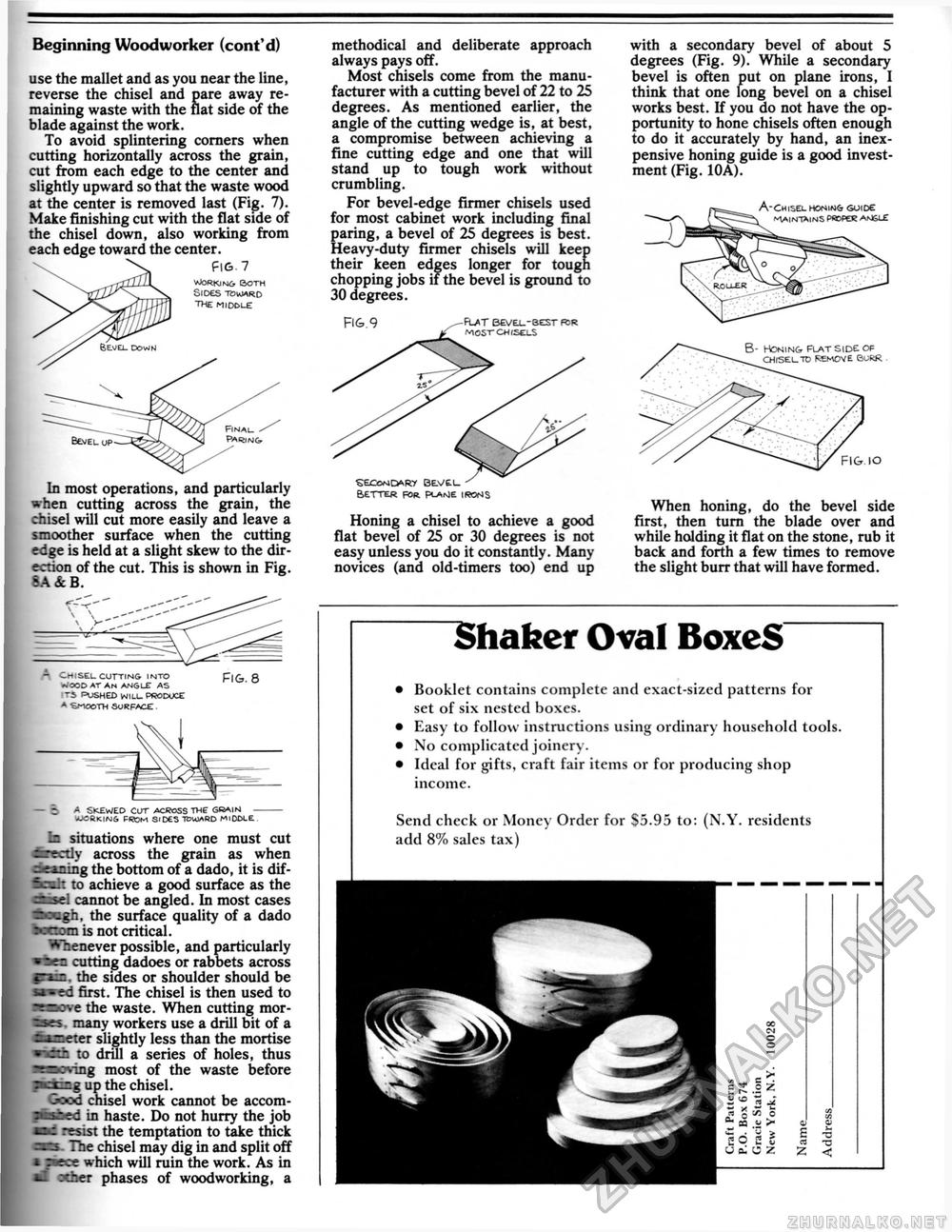

Beginning Woodworker (cont'd) use the mallet and as you near the line, reverse the chisel and pare away remaining waste with the flat side of the blade against the work. To avoid splintering corners when cutting horizontally across the grain, cut from each edge to the center and slightly upward so that the waste wood at the center is removed last (Fig. 7). Make finishing cut with the flat side of the chisel down, also working from each edge toward the center. chisel will cut more easily and leave a smoother surface when the cutting edge is held at a slight skew to the direction of the cut. This is shown in Fig. 8A&B. A Chisel cutting into g wood at AN angle: as ' Ti pushed will produce A smooth surface. — ; A SKEWED CUT ACROSS THE GRAIN -WORKING PROM SI DCS TOWARD MIDDLE In situations where one must cut Erectly across the grain as when fining the bottom of a dado, it is differ!: to achieve a good surface as the ~-sd cannot be angled. In most cases ^cugh, the surface quality of a dado is not critical. *~henever possible, and particularly •■sen cutting dadoes or rabbets across pu. the sides or shoulder should be ii*ed first. The chisel is then used to -ttaove the waste. When cutting mor-^ses. many workers use a drill bit of a r^reter slightly less than the mortise •idth to drill a series of holes, thus moving most of the waste before p^ng up the chisel. jood chisel work cannot be accom-aiiied in haste. Do not hurry the job resist the temptation to take thick 33 The chisel may dig in and split off * nece which will ruin the work. As in ti xher phases of woodworking, a methodical and deliberate approach always pays off. Most chisels come from the manufacturer with a cutting bevel of 22 to 25 degrees. As mentioned earlier, the angle of the cutting wedge is, at best, a compromise between achieving a fine cutting edge and one that will stand up to tough work without crumbling. For bevel-edge firmer chisels used for most cabinet work including final paring, a bevel of 25 degrees is best. Heavy-duty firmer chisels will keep their keen edges longer for tough chopping jobs if the bevel is ground to 30 degrees. Better for planie irons Honing a chisel to achieve a good flat bevel of 25 or 30 degrees is not easy unless you do it constantly. Many novices (and old-timers too) end up with a secondary bevel of about 5 degrees (Fig. 9). While a secondary bevel is often put on plane irons, I think that one long bevel on a chisel works best. If you do not have the opportunity to hone chisels often enough to do it accurately by hand, an inexpensive honing guide is a good investment (Fig. 10A). When honing, do the bevel side first, then turn the blade over and while holding it flat on the stone, rub it back and forth a few times to remove the slight burr that will have formed. Shaker Oval BoxeS • Booklet contains complete and exact-sizcd patterns for set of six nested boxes. • Easy to follow instructions using ordinary household tools. • No complicated joinery. • Ideal for gifts, craft fair items or for producing shop income. Send check or Money Order for $5.95 to: (N.Y. residents add 8% sales tax) |