Woodworker's Journal 1980-4-5, страница 15

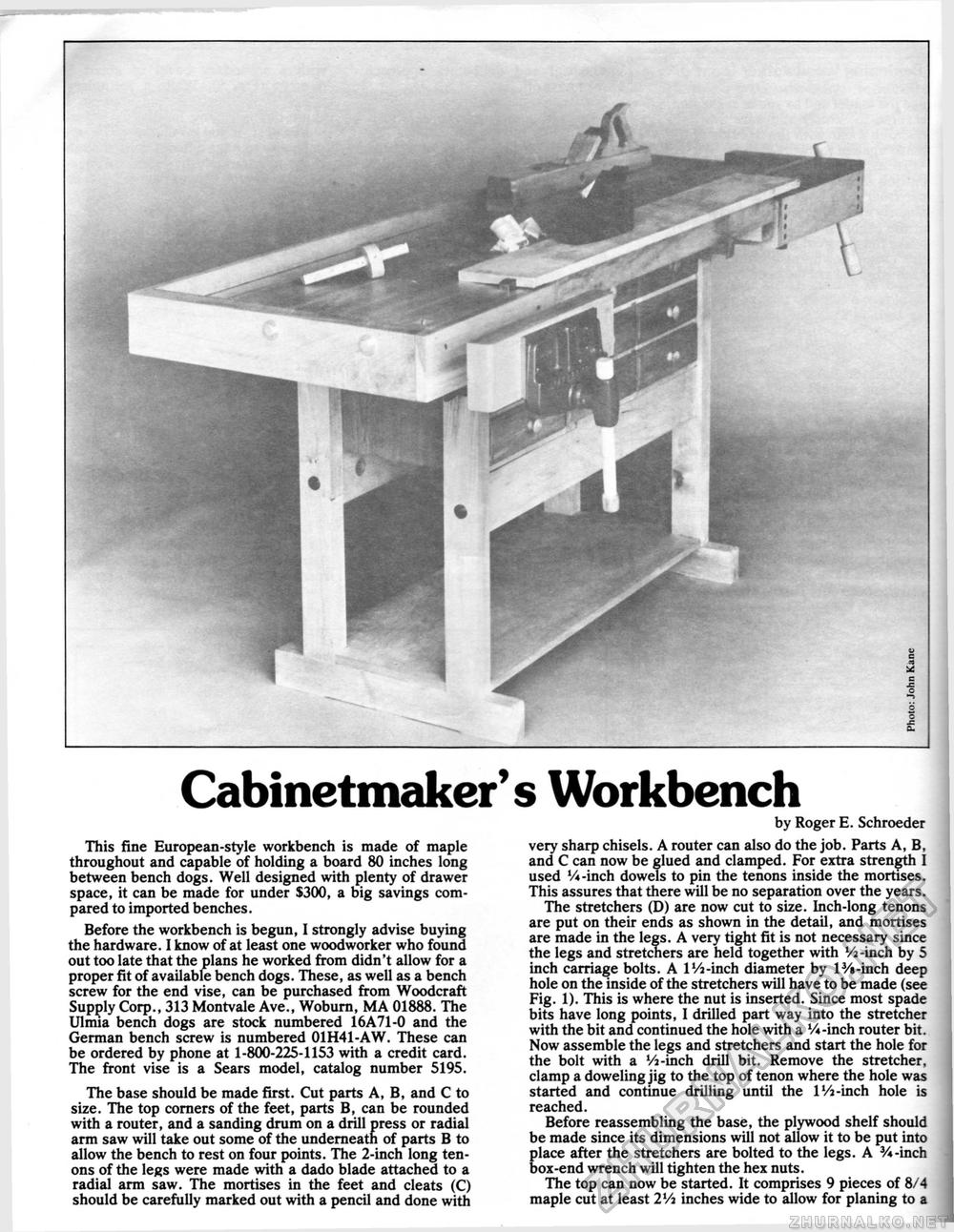

Cabinetmaker* s Workbenchby Roger E. Schroeder This fine European-style workbench is made of maple throughout and capable of holding a board 80 inches long between bench dogs. Well designed with plenty of drawer space, it can be made for under $300, a big savings compared to imported benches. Before the workbench is begun, I strongly advise buying the hardware. I know of at least one woodworker who found out too late that the plans he worked from didn't allow for a proper fit of available bench dogs. These, as well as a bench screw for the end vise, can be purchased from Woodcraft Supply Corp., 313 Montvale Ave., Woburn, MA 01888. The Ulmia bench dogs are stock numbered 16A71-0 and the German bench screw is numbered 01H41-AW. These can be ordered by phone at 1-800-225-1153 with a credit card. The front vise is a Sears model, catalog number 5195. The base should be made first. Cut parts A, B, and C to size. The top corners of the feet, parts B, can be rounded with a router, and a sanding drum on a drill press or radial arm saw will take out some of the underneath of parts B to allow the bench to rest on four points. The 2-inch long tenons of the legs were made with a dado blade attached to a radial arm saw. The mortises in the feet and cleats (C) should be carefully marked out with a pencil and done with very sharp chisels. A router can also do the job. Parts A, B, and C can now be glued and clamped. For extra strength I used Vi-inch dowels to pin the tenons inside the mortises. This assures that there will be no separation over the years. The stretchers (D) are now cut to size. Inch-long tenons are put on their ends as shown in the detail, and mortises are made in the legs. A very tight fit is not necessary since the legs and stretchers are held together with '/a-inch by 5 inch carriage bolts. A 1'/a-inch diameter by l3/»-inch deep hole on the inside of the stretchers will have to be made (see Fig. 1). This is where the nut is inserted. Since most spade bits have long points, I drilled part way into the stretcher with the bit and continued the hole with a Vi-inch router bit. Now assemble the legs and stretchers and start the hole for the bolt with a Vi-inch drill bit. Remove the stretcher, clamp a doweling jig to the top of tenon where the hole was started and continue drilling until the 1 Vi-inch hole is reached. Before reassembling the base, the plywood shelf should be made since its dimensions will not allow it to be put into place after the stretchers are bolted to the legs. A V*-inch box-end wrench will tighten the hex nuts. The top can now be started. It comprises 9 pieces of 8/4 maple cut at least 2Vi inches wide to allow for planing to a |