Woodworker's Journal 1983-7-4, страница 39

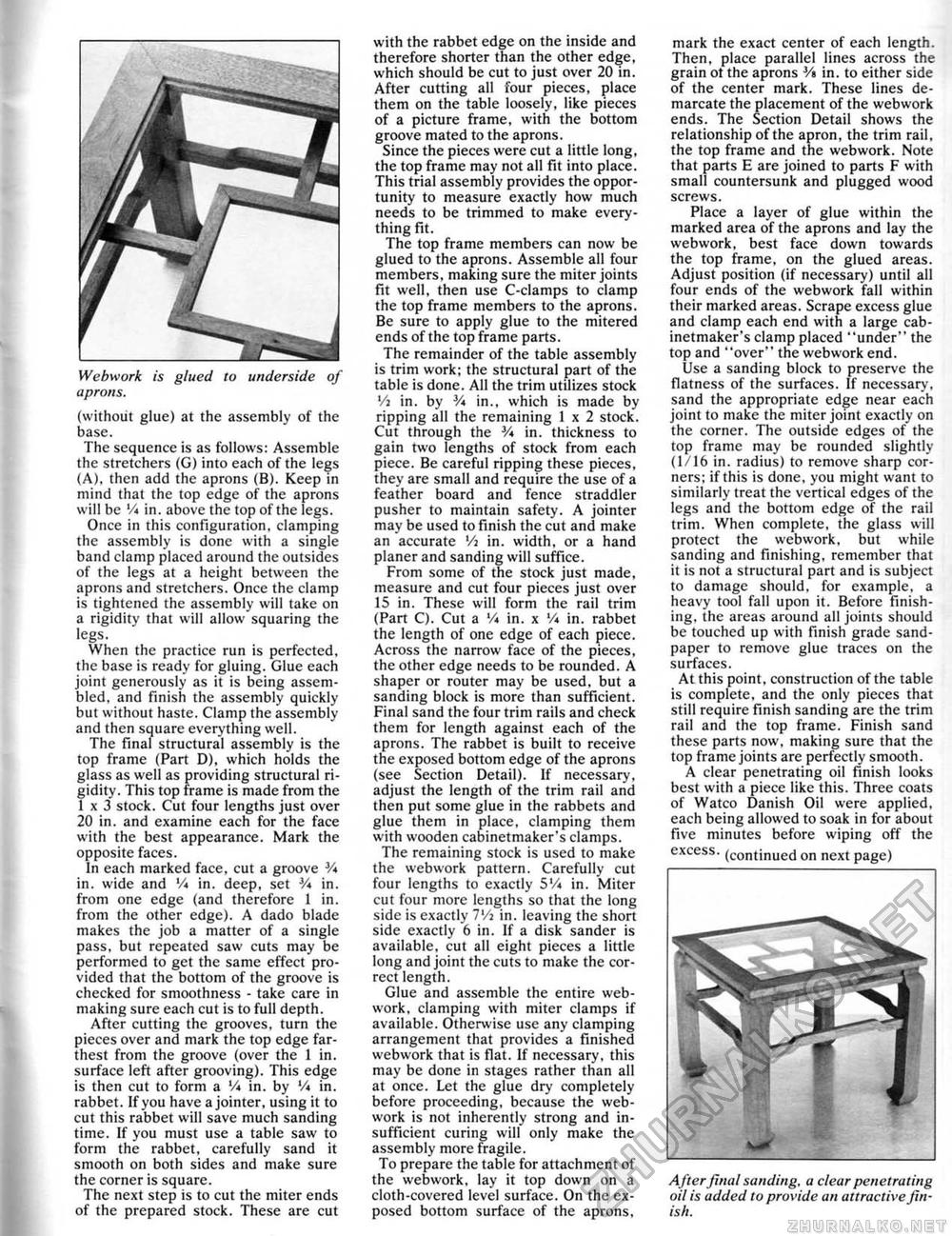

Webwork is glued to underside of aprons. (without glue) at the assembly of the base. The sequence is as follows: Assemble the stretchers (G) into each of the legs (A), then add the aprons (B). Keep in mind that the top edge of the aprons will be V* in. above the top of the legs. Once in this configuration, clamping the assembly is done with a single band clamp placed around the outsides of the legs at a height between the aprons and stretchers. Once the clamp is tightened the assembly will take on a rigidity that will allow squaring the legs. When the practice run is perfected, the base is ready for gluing. Glue each joint generously as it is being assembled, and Finish the assembly quickly but without haste. Clamp the assembly and then square everything well. The final structural assembly is the top frame (Part D), which holds the glass as well as providing structural rigidity. This top frame is made from the 1x3 stock. Cut four lengths just over 20 in. and examine each for the face with the best appearance. Mark the opposite faces. In each marked face, cut a groove V* in. wide and V* in. deep, set V* in. from one edge (and therefore 1 in. from the other edge). A dado blade makes the job a matter of a single pass, but repeated saw cuts may be performed to get the same effect provided that the bottom of the groove is checked for smoothness - take care in making sure each cut is to full depth. After cutting the grooves, turn the pieces over and mark the top edge farthest from the groove (over the 1 in. surface left after grooving). This edge is then cut to form a V« in. by V* in. rabbet. If you have a jointer, using it to cut this rabbet will save much sanding time. If you must use a table saw to form the rabbet, carefully sand it smooth on both sides and make sure the corner is square. The next step is to cut the miter ends of the prepared stock. These are cut with the rabbet edge on the inside and therefore shorter than the other edge, which should be cut to just over 20 in. After cutting all four pieces, place them on the table loosely, like pieces of a picture frame, with the bottom groove mated to the aprons. Since the pieces were cut a little long, the top frame may not all fit into place. This trial assembly provides the opportunity to measure exactly how much needs to be trimmed to make everything fit. The top frame members can now be glued to the aprons. Assemble all four members, making sure the miter joints fit well, then use C-clamps to clamp the top frame members to the aprons. Be sure to apply glue to the mitered ends of the top frame parts. The remainder of the table assembly is trim work; the structural part of the table is done. All the trim utilizes stock '/: in. by V* in., which is made by ripping all the remaining 1 x 2 stock. Cut through the V* in. thickness to gain two lengths of stock from each piece. Be careful ripping these pieces, they are small and require the use of a feather board and fence straddler pusher to maintain safety. A jointer may be used to finish the cut and make an accurate lA in. width, or a hand planer and sanding will suffice. From some of the stock just made, measure and cut four pieces just over 15 in. These will form the rail trim (Part C). Cut a V* in. x 'A in. rabbet the length of one edge of each piece. Across the narrow face of the pieces, the other edge needs to be rounded, A shaper or router may be used, but a sanding block is more than sufficient. Final sand the four trim rails and check them for length against each of the aprons. The rabbet is built to receive the exposed bottom edge of the aprons (see Section Detail). If necessary, adjust the length of the trim rail and then put some glue in the rabbets and glue them in place, clamping them with wooden cabinetmaker's clamps. The remaining stock is used to make the webwork pattern. Carefully cut four lengths to exactly 5V* in. Miter cut four more lengths so that the long side is exactly 7'/i in. leaving the short side exactly 6 in. If a disk sander is available, cut all eight pieces a little long and joint the cuts to make the correct length. Glue and assemble the entire webwork, clamping with miter clamps if available. Otherwise use any clamping arrangement that provides a finished webwork that is flat. If necessary, this may be done in stages rather than all at once. Let the glue dry completely before proceeding, because the webwork is not inherently strong and insufficient curing will only make the assembly more fragile. To prepare the table for attachment of the webwork, lay it top down on a cloth-covered level surface. On the exposed bottom surface of the aprons, mark the exact center of each length. Then, place parallel lines across the grain ot the aprons Vt in. to either side of the center mark. These lines demarcate the placement of the webwork ends. The Section Detail shows the relationship of the apron, the trim rail, the top frame and the webwork. Note that parts E are joined to parts F with small countersunk and plugged wood screws. Place a layer of glue within the marked area of the aprons and lay the webwork, best face down towards the top frame, on the glued areas. Adjust position (if necessary) until all four ends of the webwork fall within their marked areas. Scrape excess glue and clamp each end with a large cabinetmaker's clamp placed "under" the top and "over" the webwork end. Use a sanding block to preserve the flatness of the surfaces. If necessary, sand the appropriate edge near each joint to make the miter joint exactly on the corner. The outside edges of the top frame may be rounded slightly (1/16 in. radius) to remove sharp corners; if this is done, you might want to similarly treat the vertical edges of the legs and the bottom edge of the rail trim. When complete, the glass will protect the webwork. but while sanding and finishing, remember that it is not a structural part and is subject to damage should, for example, a heavy tool fall upon it. Before finishing. the areas around all joints should be touched up with finish grade sandpaper to remove glue traces on the surfaces. At this point, construction of the table is complete, and the only pieces that still require finish sanding are the trim rail and the top frame. Finish sand these parts now, making sure that the top frame joints are perfectly smooth. A clear penetrating oil finish looks best with a piece like this. Three coats of Watco Danish Oil were applied, each being allowed to soak in for about five minutes before wiping off the excess, (continued on next page) After final sanding, a clear penetrating oil is added to provide an attractive finish. |