Woodworker's Journal 1983-7-5, страница 50

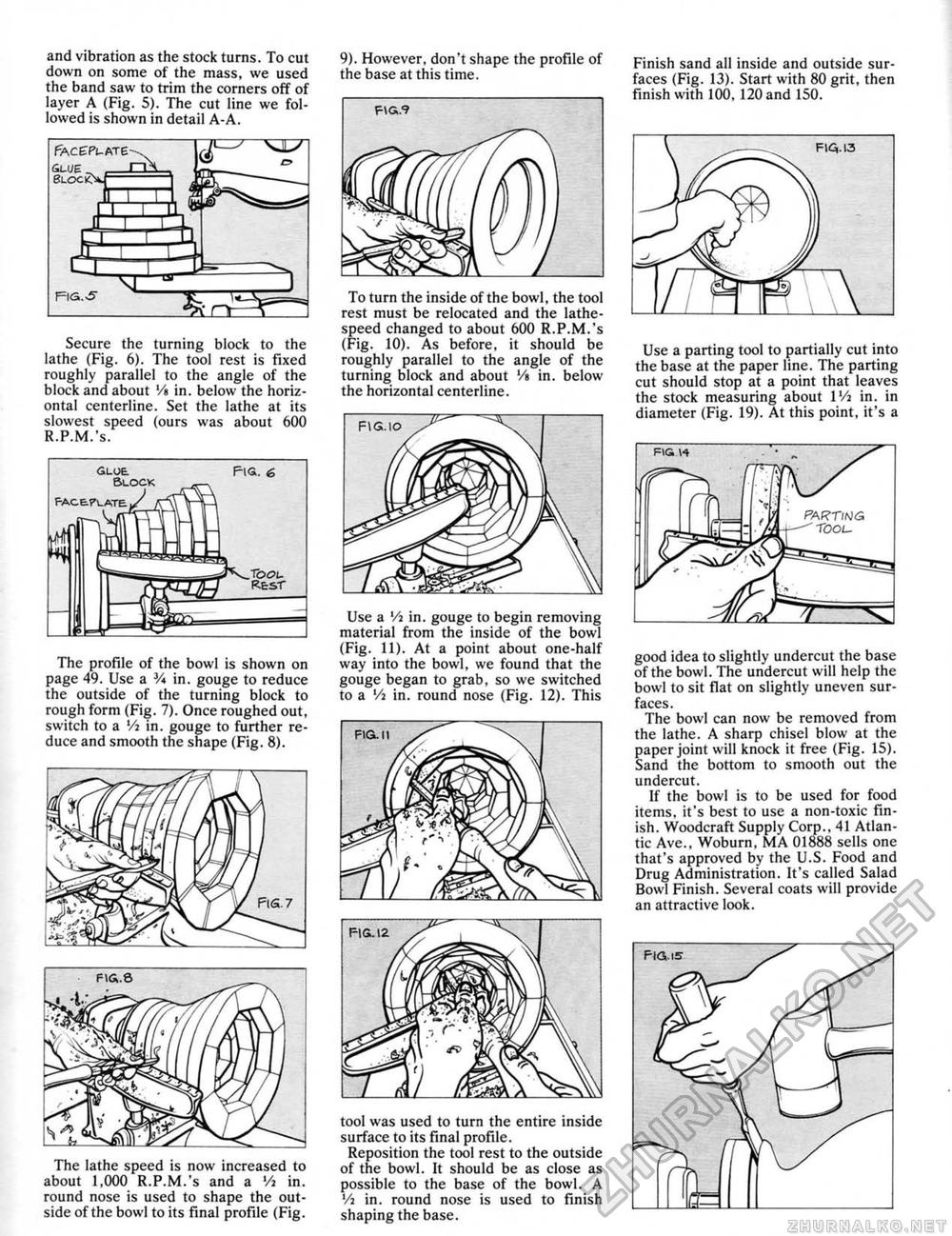

and vibration as the stock turns. To cut down on some of the mass, we used the band saw to trim the corners off of layer A (Fig. 5). The cut line we followed is shown in detail A-A. Secure the turning block to the lathe (Fig. 6). The tool rest is fixed roughly parallel to the angle of the block and about 'A in. below the horizontal centerline. Set the lathe at its slowest speed (ours was about 600 R.P.M.'s. The profde of the bowl is shown on page 49. Use a 3A in. gouge to reduce the outside of the turning block to rough form (Fig. 7). Once roughed out, switch to a '/j in. gouge to further reduce and smooth the shape (Fig. 8). The lathe speed is now increased to about 1,000 R.P.M.'s and a Vi in. round nose is used to shape the outside of the bowl to its final profile (Fig. 9). However, don't shape the profile of the base at this time. F\a.9 To turn the inside of the bowl, the tool rest must be relocated and the lathe-speed changed to about 600 R.P.M.'s (Fig. 10). As before, it should be roughly parallel to the angle of the turning block and about '/« in, below the horizontal centerline. Use a 'A in. gouge to begin removing material from the inside of the bowl (Fig. 11). At a point about one-half way into the bowl, we found that the gouge began to grab, so we switched to a 'A in, round nose (Fig. 12). This tool was used to turn the entire inside surface to its final profile. Reposition the tool rest to the outside of the bowl. It should be as close as possible to the base of the bowl. A lA in. round nose is used to finish shaping the base. Finish sand all inside and outside surfaces (Fig. 13). Start with 80 grit, then finish with 100, 120 and 150. Use a parting tool to partially cut into the base at the paper Sine. The parting cut should stop at a point that leaves the stock measuring about VA in. in diameter (Fig. 19), At this point, it's a good idea to slightly undercut the base of the bowl. The undercut will help the bowi to sit flat on slightly uneven surfaces. The bowl can now be removed from the lathe. A sharp chisel blow at the paper joint will knock it free (Fig. 15). Sand the bottom to smooth out the undercut. If the bowl is to be used for food items, it's best to use a non-toxic finish. Woodcraft Supply Corp., 41 Atlantic Ave., Woburn, MA 01888 sells one that's approved by the U.S. Food and Drug Administration. It's called Salad Bowl Finish. Several coats will provide an attractive look. 7 PARTING Tool. |