Woodworker's Journal 1983-7-5, страница 54

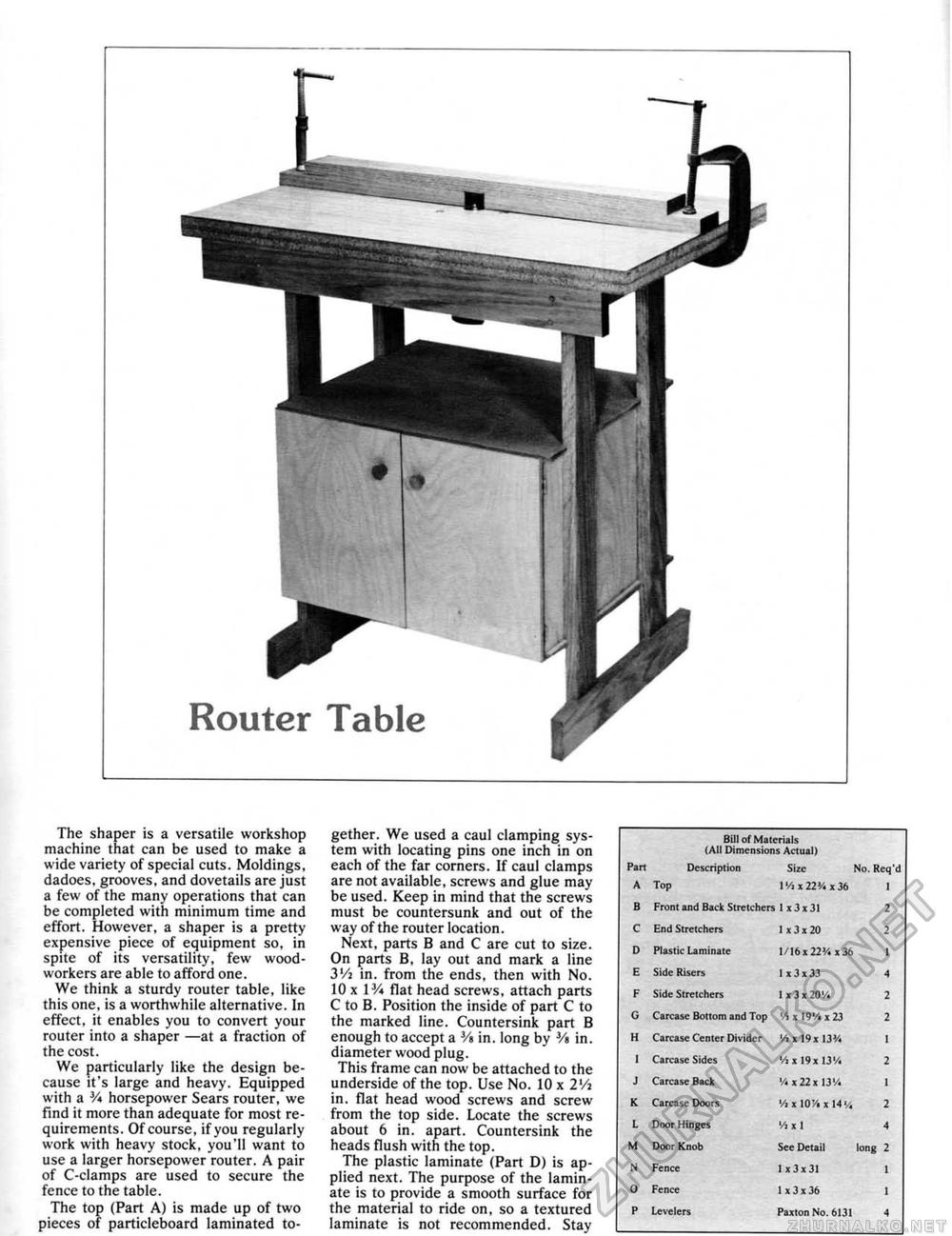

The shaper is a versatile workshop machine that can be used to make a wide variety of special cuts. Moldings, dadoes, grooves, and dovetails are just a few of the many operations that can be completed with minimum time and effort. However, a shaper is a pretty expensive piece of equipment so, in spite of its versatility, few woodworkers are able to afford one. We think a sturdy router table, like this one, is a worthwhile alternative. In effect, it enables you to convert your router into a shaper —at a fraction of the cost. We particularly like the design because it's large and heavy. Equipped with a 3A horsepower Sears router, we find it more than adequate for most requirements. Of course, if you regularly work with heavy stock, you'll want to use a larger horsepower router. A pair of C-clamps are used to secure the fence to the table. The top (Part A) is made up of two pieces of particleboard laminated to gether. We used a caul clamping system with locating pins one inch in on each of the far corners. If caul clamps are not available, screws and glue may be used. Keep in mind that the screws must be countersunk and out of the way of the router location. Next, parts B and C are cut to size. On parts B, lay out and mark a line 3'/i in. from the ends, then with No, 10 x Wa fiat head screws, attach parts C to B. Position the inside of part C to the marked line. Countersink pan B enough to accept a Vt in, long by Vt in. diameter wood plug. This frame can now be attached to the underside of the top. Use No. 10 x 2"/i in. flat head wood screws and screw from the top side. Locate the screws about 6 in, apart. Countersink the heads flush with the top. The plastic laminate (Part D) is applied next. The purpose of the laminate is to provide a smooth surface for the material to ride on, so a textured laminate is not recommended. Stay

Router Table |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||