Woodworker's Journal 1983-7-6, страница 43

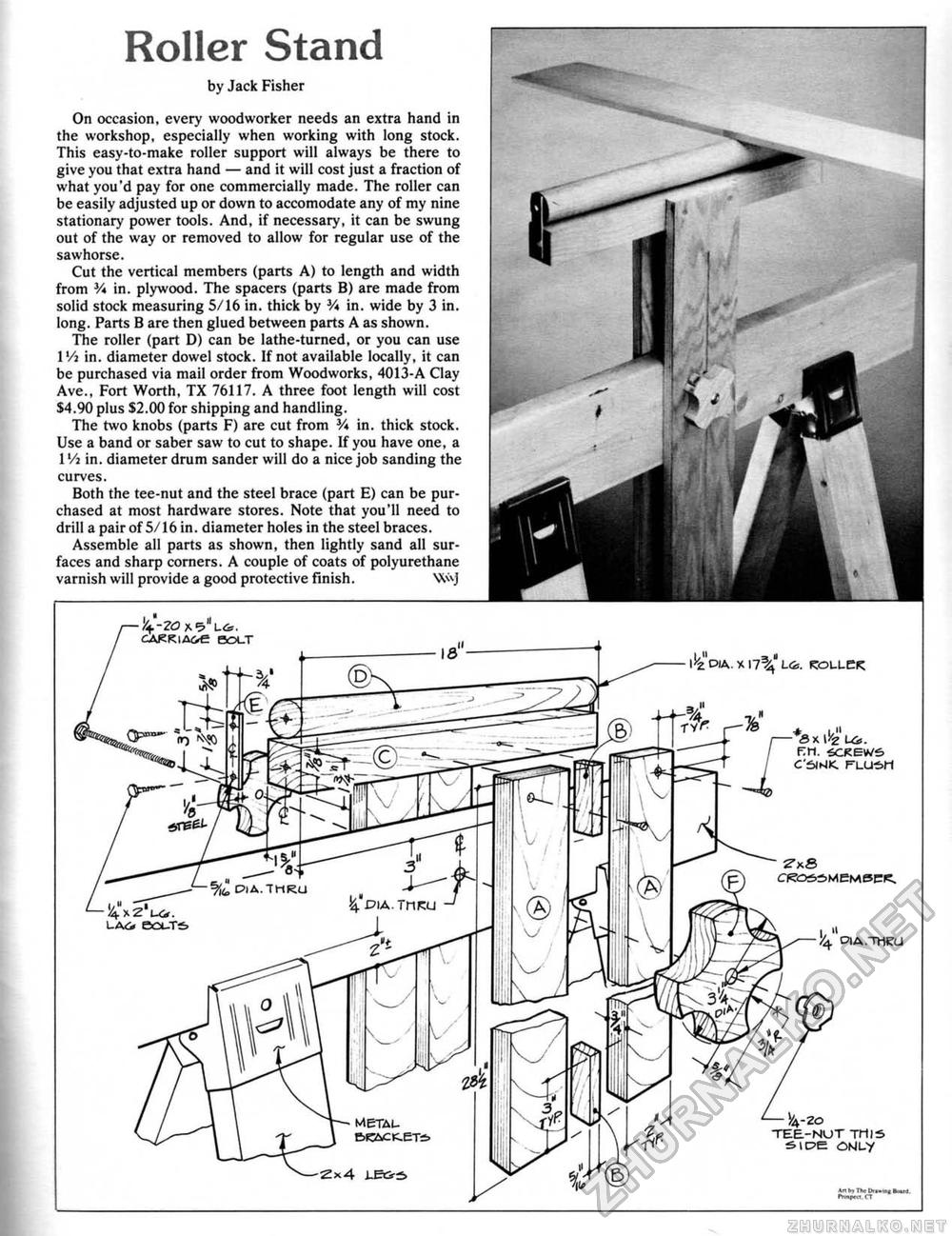

Roller Standby Jack Fisher On occasion, every woodworker needs an extra hand in the workshop, especially when working with long stock. This easy-to-make roller support will always be there to give you that extra hand — and it will cost just a fraction of what you'd pay for one commercially made. The roller can be easily adjusted up or down to accomodate any of my nine stationary power tools. And, if necessary, it can be swung out of the way or removed to allow for regular use of the sawhorse. Cut the vertical members (parts A) to length and width from V* in. plywood. The spacers (parts B) are made from solid stock measuring 5/16 in. thick by 3A in. wide by 3 in. long. Parts B are then glued between parts A as shown. The roller (part D) can be lathe-turned, or you can use l'/j in. diameter dowel stock. If not available locally, it can be purchased via mail order from Woodworks, 4013-A Clay Ave., Fort Worth. TX 76117. A three foot length will cost $4.90 plus $2.00 for shipping and handling. The two knobs (parts F) are cut from ¥* in. thick stock. Use a band or saber saw to cut to shape. If you have one, a 1 Vi in. diameter drum sander will do a nice job sanding the curves. Both the tee-nut and the steel brace (part E) can be purchased at most hardware stores. Note that you'll need to drill a pair of 5/16 in. diameter holes in the steel braces. Assemble all parts as shown, then lightly sand all surfaces and sharp corners. A couple of coats of polyurethane varnish will provide a good protective finish. W\1 |