Woodworker's Journal 1983-7-6, страница 46

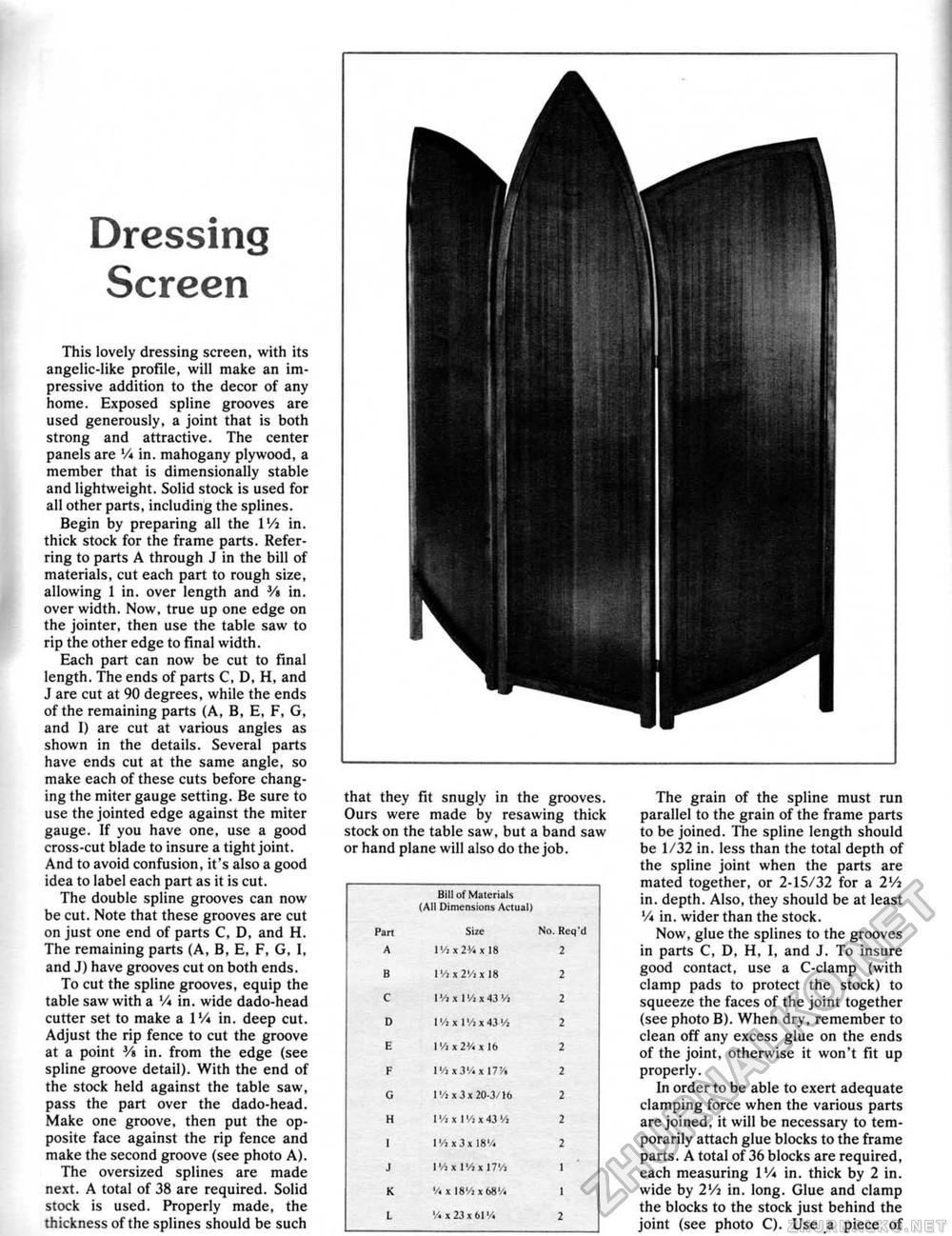

Dressing ScreenThis iovely dressing screen, with its angelic-like profile, will make an impressive addition to the decor of any home. Exposed spline grooves are used generously, a joint that is both strong and attractive. The center panels are V* in. mahogany plywood, a member that is dimensionally stable and lightweight. Solid stock is used for all other parts, including the splines. Begin by preparing ail the l'/i in. thick stock for the frame parts. Referring to parts A through J in the bill of materials, cut each part to rough size, allowing 1 in. over length and % in. over width. Now, true up one edge on the jointer, then use the table saw to rip the other edge to final width. Each part can now be cut to finai length. The ends of parts C, D, H, and J are cut at 90 degrees, while the ends of the remaining parts (A, B, E, F, G. and I) are cut at various angies as shown in the details. Several parts have ends cut at the same angle, so make each of these cuts before changing the miter gauge setting. Be sure to use the jointed edge against the miter gauge. If you have one, use a good cross-cut blade to insure a tight joint. And to avoid confusion, it's also a good idea to label each part as it is cut. The double spline grooves can now be cut. Note that these grooves are cut on just one end of parts C, D, and H. The remaining parts {A, B, E, F, G, 1, and J) have grooves cut on both ends. To cut the spline grooves, equip the table saw with a V* in. wide dado-head cutter set to make a \V* in. deep cut. Adjust the rip fence to cut the groove at a point % in. from the edge (see spline groove detail). With the end of the stock held against the table saw, pass the part over the dado-head. Make one groove, then put the opposite face against the rip fence and make the second groove (see photo A). The oversized splines are made next. A total of 38 are required. Solid stock is used. Properly made, the thickness of the splines should be such The grain of the spline must run parallel to the grain of the frame parts to be joined. The spline iength should be 1/32 in. less than the total depth of the spline joint when the parts are mated together, or 2-15/32 for a 2Vj in. depth. Also, they should be at least V* in. wider than the stock. Now, glue the splines to the grooves in parts C, D, H, I, and J. To insure good contact, use a C-clamp (with clamp pads to protect the stock) to squeeze the faces of the joint together (see photo B). When dry, remember to clean off any excess glue on the ends of the joint, otherwise it won't fit up properly. In order to be able to exert adequate clamping force when the various parts are joined, it will be necessary to temporarily attach glue blocks to the frame parts. A total of 36 blocks are required, each measuring IV* in. thick by 2 in. wide by 2Vi in. long. Glue and clamp the blocks to the stock just behind the joint (see photo C). Use a piece of that they fit snugly in the grooves. Ours were made by resawing thick stock on the table saw, but a band saw or hand plane will also do the job.

|