Woodworker's Journal 1984-8-1, страница 41

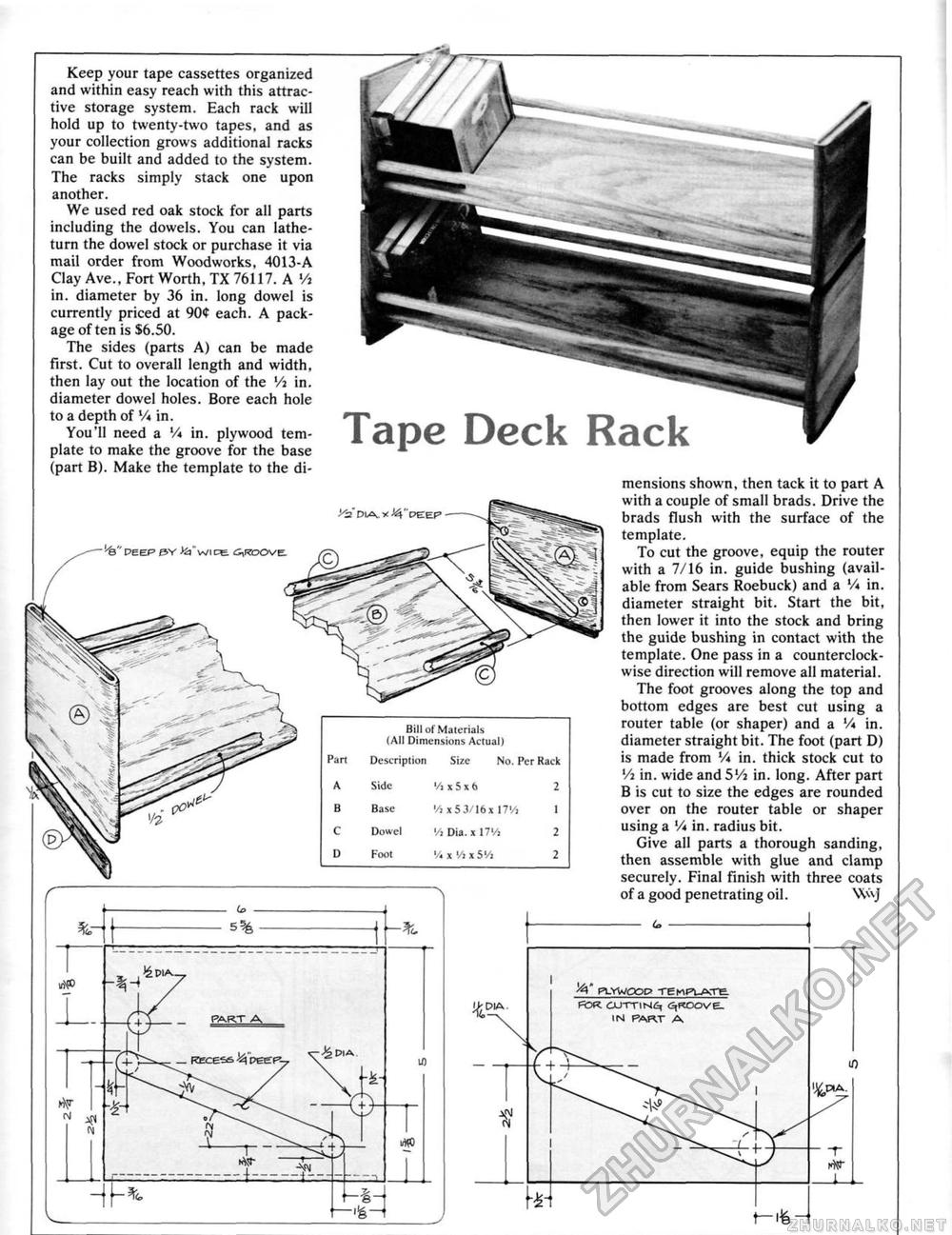

Keep your tape cassettes organized and within easy reach with this attractive storage system. Each rack will hold up to twenty-two tapes, and as your collection grows additional racks can be built and added to the system. The racks simply stack one upon another. We used red oak stock for all parts including the dowels. You can lathe-turn the dowel stock or purchase it via mail order from Woodworks, 4013-A Clay Ave., Fort Worth, TX 76117. A Va in. diameter by 36 in. long dowel is currently priced at 90<t each. A package of ten is $6.50. The sides (parts A) can be made first. Cut to overall length and width, then lay out the location of the Vi in. diameter dowel holes. Bore each hole to a depth of V«in. You'll need a V* in, plywood template to make the groove for the base (part B). Make the template to the di- Tape Deck Rack yd PLA.. *

mensions shown, then tack it to part A with a couple of small brads. Drive the brads flush with the surface of the template. To cut the groove, equip the router with a 7/16 in. guide bushing (available from Sears Roebuck) and a V* in. diameter straight bit. Start the bit, then lower it into the stock and bring the guide bushing in contact with the template. One pass in a counterclockwise direction will remove all material. The foot grooves along the top and bottom edges are best cut using a router table (or shaper) and a V* in. diameter straight bit. The foot (part D) is made from V* in. thick stock cut to Vi in. wide and 5Vi in. long. After part B is cut to size the edges are rounded over on the router table or shaper using a '/«in. radius bit. Give all parts a thorough sanding, then assemble with glue and clamp securely. Final finish with three coats of a good penetrating oil. W\J PLYvJOOC tewpwe. FOR OJTTIN(% i^KOOVB- 1M PART A |

||||||||||||||||||