Woodworker's Journal 1984-8-3, страница 20

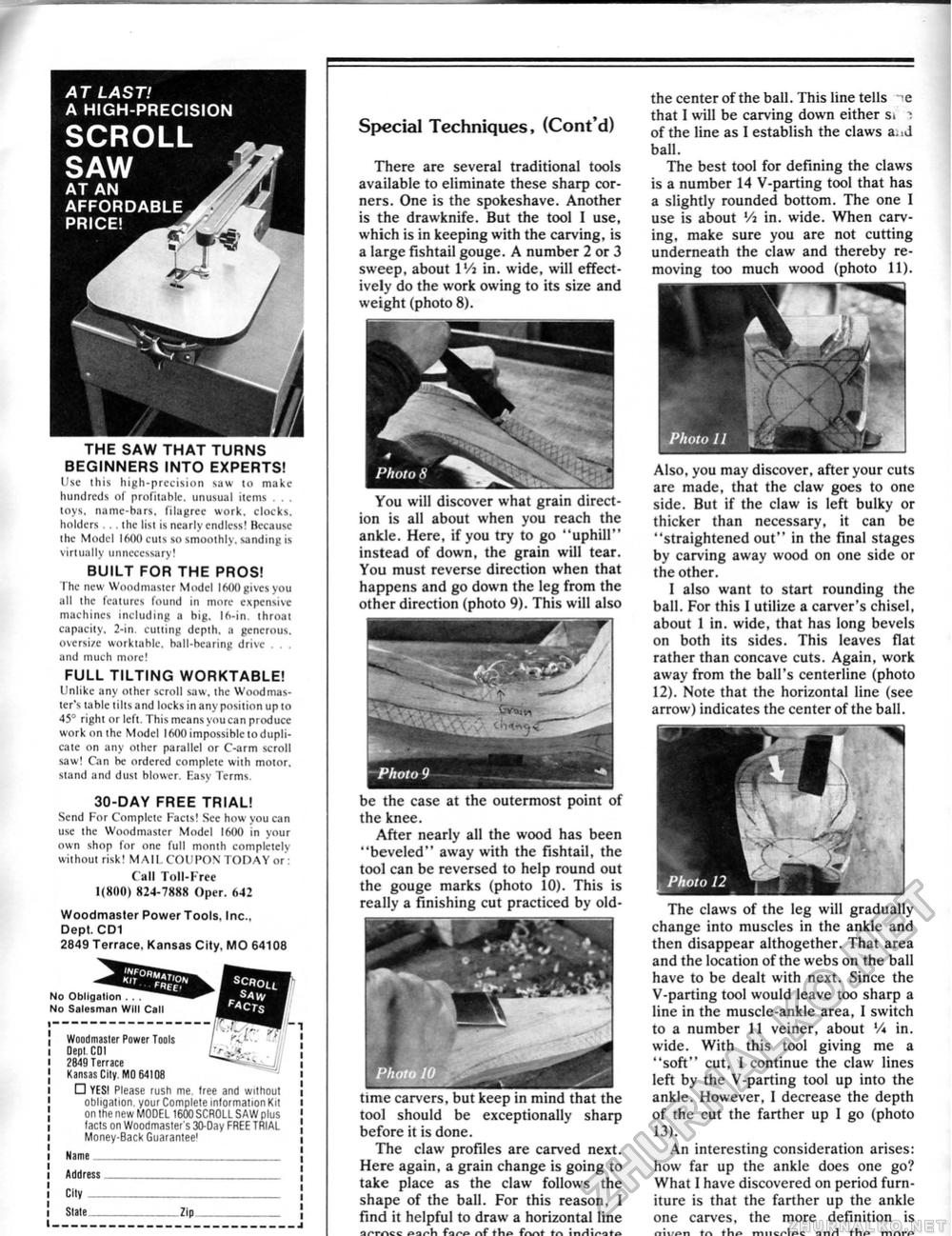

AT LAST! A HIGH-PRECISION SCROLL SAW AT AN AFFORD PRICE! Address Special Techniques, (Cont'd) There are several traditional tools available to eliminate these sharp corners. One is the spokeshave. Another is the drawknife. But the tool I use, which is in keeping with the carving, is a large fishtail gouge. A number 2 or 3 sweep, about ll/i in. wide, will effectively do the work owing to its size and weight (photo 8). THE SAW THAT TURNS BEGINNERS INTO EXPERTS! Use this high-precision saw (o make hundreds of profitable, unusual items . . . toys, name-bars, filagree work, clocks, holders , .the list is nearly endless! Because the Model 16(10 cuts so smoothly, sanding is virtually unnecessary! BUILT FOR THE PROS! The new Woodmaster Model 1600 gives you all the features found in more expensive machines including a big. 16-in. throat capacity, 2-in. cutting depth, a generous, oversize worktable. hall-hearing drive . . . and much more! FULL TILTING WORKTABLE! Unlike any other scroll saw, the Woodmas-ter's table tills and locks in any position up to 45° right or left. This means vou can producc work on the Model 16(10 impossible to duplicate on any other parallel or C-arm scroll saw! Can be ordered complete with motor, stand and dust blower. Easy Terms. 30-DAY FREE TRIAL! Send For Complete Facts! See how you can use the Woodmaster Model 1600 in your own shop for one full month compleielv without risk! MAIL COUPON TODAY or : C all Toll-Free 1(800) 824-7888 Oper. 642 Woodmaster Power Tools, Inc., Dept. CD1 2849 Terrace, Kansas City, MO 64108 No Obligation No Salesman Will Call Woodmasler Power Tools Dept CD1 ZB49 Terrace Kansas City. MO to 100 □ VESI Please rush me. free and without obligation, your Complele information Kit on I fie new MODEL 1600 SCROLL SAW plus lacts on Wcodmaster's 30-0ay FREE TRIAL Money-Back Guarantee1 Name_ You will discover what grain direction is all about when you reach the ankle. Here, if you try to go "uphill" instead of down, the grain will tear. You must reverse direction when that happens and go down the leg from the other direction (photo 9). This will also be the case at the outermost point of the knee. After nearly all the wood has been "beveled" away with the fishtail, the tool can be reversed to help round out the gouge marks (photo 10). This is really a finishing cut practiced by old- the center of the ball. This line tells ie that I will be carving down either Si of the line as I establish the claws a; id ball. The best tool for defining the claws is a number 14 V-parting tool that has a slightly rounded bottom. The one I use is about Vi in. wide. When carving, make sure you are not cutting underneath the claw and thereby removing too much wood (photo 11). Also, you may discover, after your cuts are made, that the claw goes to one side. But if the claw is left bulky or thicker than necessary, it can be "straightened out" in the final stages by carving away wood on one side or the other, I also want to start rounding the ball. For this I utilize a carver's chisel, about 1 in. wide, that has long bevels on both its sides. This leaves flat rather than concave cuts. Again, work away from the ball's centerline (photo 12). Note that the horizontal line (see arrow) indicates the center of the ball. The claws of the leg will gradually change into muscles in the ankle and then disappear althogether. That area and the location of the webs on the ball have to be dealt with next. Since the V-parting tool would leave too sharp a line in the muscle-ankle area, 1 switch to a number 11 veiner, about Vt in. wide. With this tool giving me a "soft" cut, I continue the claw lines left by the V-parting tool up into the ankle. However, I decrease the depth of the cut the farther up I go (photo 13). An interesting consideration arises: how far up the ankle does one go? What I have discovered on period furniture is that the farther up the ankle one carves, the more definition is tr\ thf* mnc^l***: anrl thf* mnrp time carvers, but keep in mind that the tool should be exceptionally sharp before it is done. The claw profiles are carved next. Here again, a grain change is going to take place as the claw follows the shape of the ball. For this reason, 1 find it helpful to draw a horizontal line arrrvee ^a^Vi farp r\f tKp fVv*t tr\ inHi^otn |