Woodworker's Journal 1984-8-4, страница 31

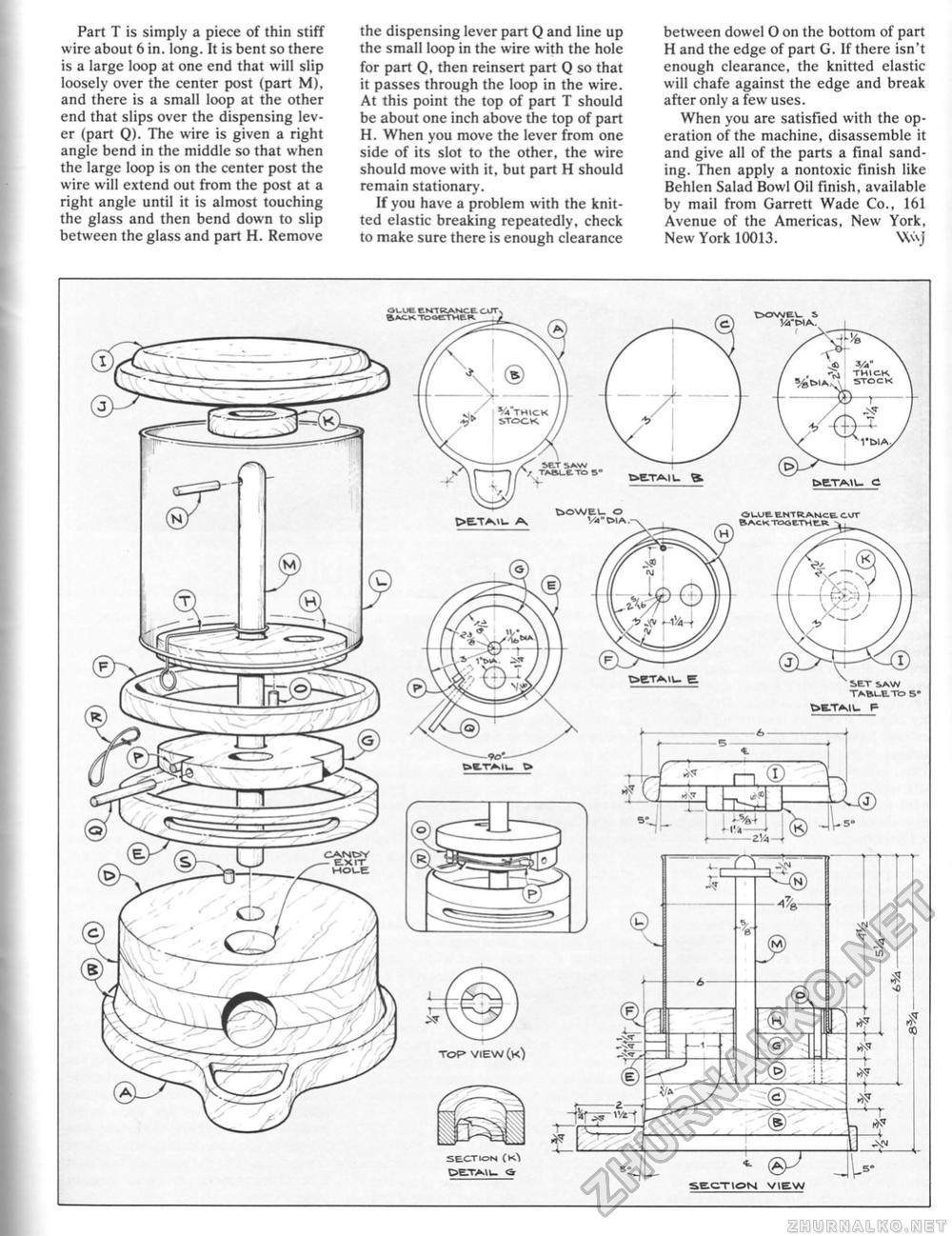

Part T is simply a piece of thin stiff wire about 6 in. long. It is bent so there is a iarge loop at one end that will slip loosely over the center post (pan M), and there is a small loop at the other end that slips over the dispensing lever (part Q). The wire is given a right angle bend in the middle so that when the large loop is on the center post the wire will extend out from the post at a right angle until it is almost touching the glass and then bend down to slip between the glass and part H. Remove the dispensing lever part Q and line up the small loop in the wire with the hole for part Q, then reinsert part Q so that it passes through the loop in the wire. At this point the top of part T should be about one inch above the top of part H. When you move the lever from one side of its slot to the other, the wire should move with it, but part H should remain stationary. If you have a problem with the knitted elastic breaking repeatedly, check to make sure there is enough clearance between dowel O on the bottom of part H and the edge of part G. If there isn't enough clearance, the knitted elastic will chafe against the edge and break after only a few uses. When you are satisfied with the operation of the machine, disassemble it and give all of the parts a final sanding. Then apply a nontoxic finish like Behlen Salad Bowl Oil finish, available by mail from Garrett Wade Co., 161 Avenue of the Americas, New York, New York 10013. Wvvj |