Woodworker's Journal 1985-9-3, страница 35

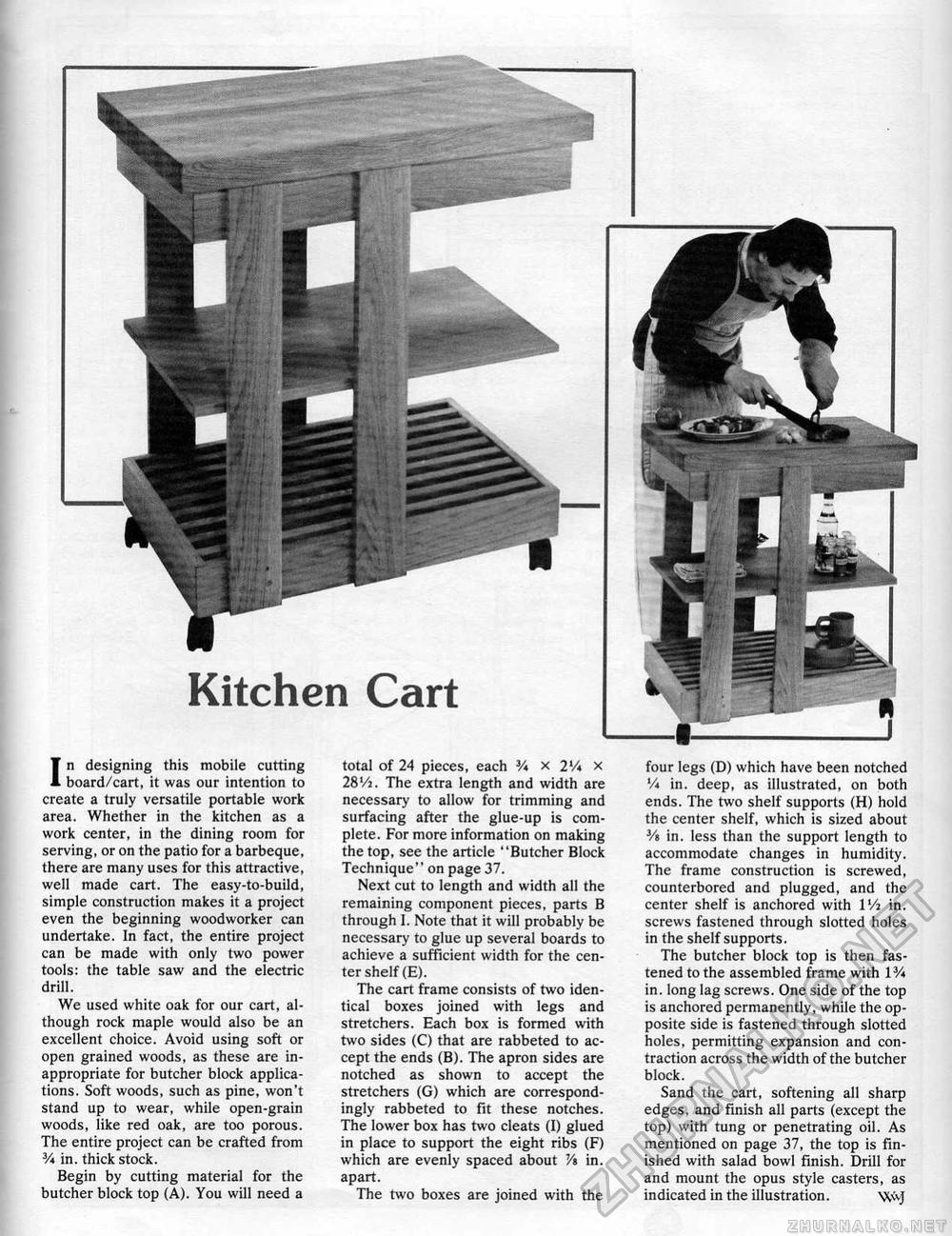

Kitchen Cart In designing this mobile cutting board/cart, it was our intention to create a truly versatile portable work area. Whether in the kitchen as a work center, in the dining room for serving, or on the patio for a barbeque, there are many uses for this attractive, well made cart. The easy-to-build, simple construction makes it a project even the beginning woodworker can undertake. In fact, the entire project can be made with only two power tools: the table saw and the electric drill. We used white oak for our cart, although rock maple would also be an excellent choice. Avoid using soft or open grained woods, as these are inappropriate for butcher block applications. Soft woods, such as pine, won't stand up to wear, while open-grain woods, like red oak, are too porous. The entire project can be crafted from 3A in. thick stock. Begin by cutting material for the butcher block top (A). You will need a total of 24 pieces, each V* x 2'A x 28Vi. The extra length and width are necessary to allow for trimming and surfacing after the glue-up is complete. For more information on making the top, see the article "Butcher Block Technique" on page 37. Next cut to length and width all the remaining component pieces, parts B through I. Note that it will probably be necessary to glue up several boards to achieve a sufficient width for the center shelf (E). The cart frame consists of two identical boxes joined with legs and stretchers. Each box is formed with two sides (C) that are rabbeted to accept the ends (B). The apron sides are notched as shown to accept the stretchers (G) which are correspondingly rabbeted to fit these notches. The lower box has two cleats (I) glued in place to support the eight ribs (F) which are evenly spaced about V» in. apart. The two boxes are joined with the four legs (D) which have been notched Vi in. deep, as illustrated, on both ends. The two shelf supports (H) hold the center shelf, which is sized about V» in, less than the support length to accommodate changes in humidity. The frame construction is screwed, counterbored and plugged, and the center shelf is anchored with 1 Vi in. screws fastened through slotted holes in the shelf supports. The butcher block top is then fastened to the assembled frame with IV* in. long lag screws. One side of the top is anchored permanently, while the opposite side is fastened through slotted holes, permitting expansion and contraction across the width of the butcher block. Sand the cart, softening all sharp edges, and finish all parts (except the top) with tung or penetrating oil. As mentioned on page 37, the top is finished with salad bowl finish. Drill for and mount the opus style casters, as indicated in the illustration. w^ |