Woodworker's Journal 1993-17-5, страница 20

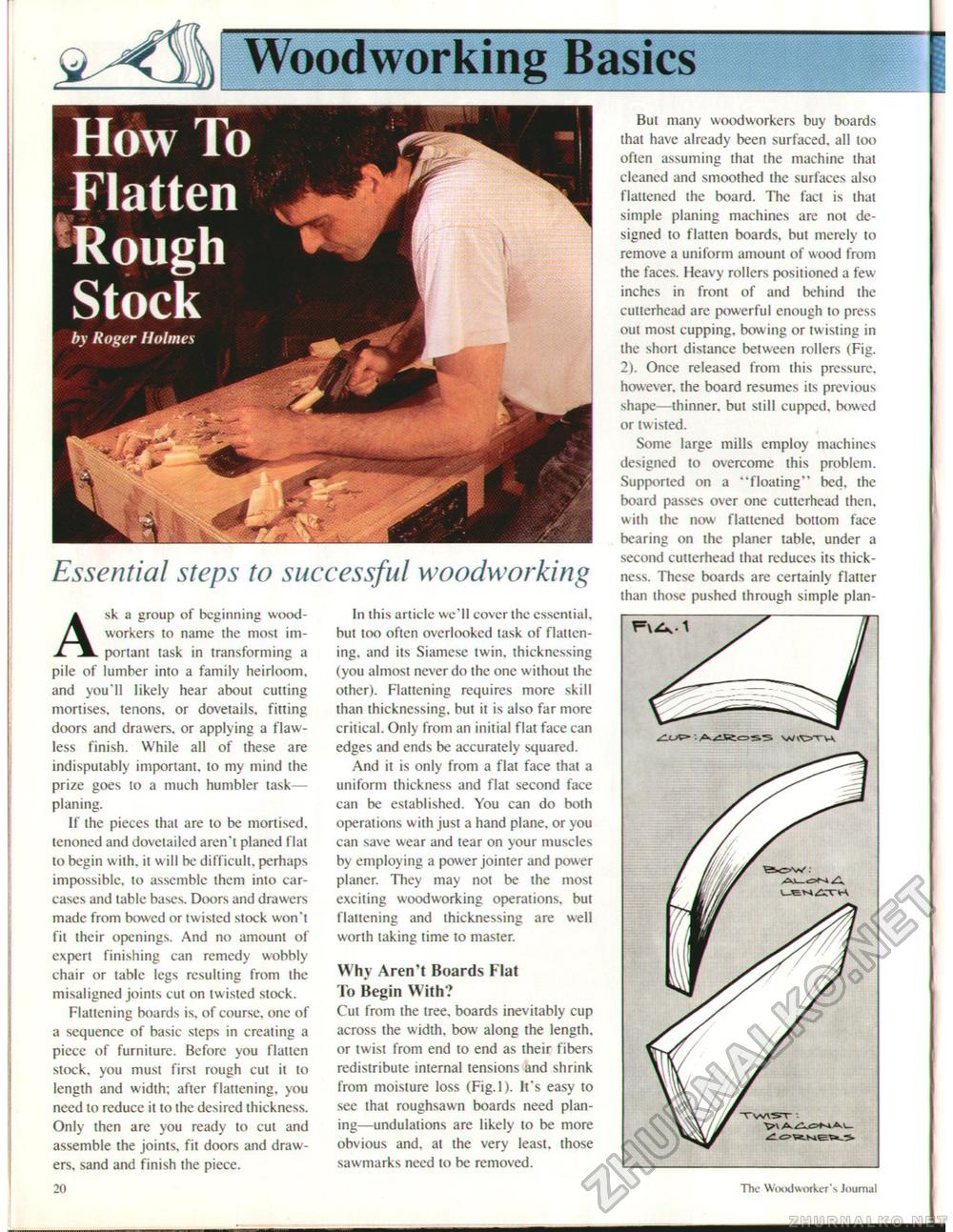

j Woodworking Basics Essential steps to successful woodworking Ask a group of beginning woodworkers to name the most important task in transforming a pile of lumber into a family heirloom, and you'll likely hear about cutting mortises, tenons, or dovetails, fitting doors and drawers, or applying a flawless finish. While all of these are indisputably important, to my mind the prize goes to a much humbler task— planing. If the pieces that are to be mortised, tenoned and dovetailed aren't planed flat to begin with, it will be difficult, perhaps impossible, to assemble them into carcases and table bases. Doors and drawers made from bowed or twisted stock won't fit their openings. And no amount of expert finishing can remedy wobbly chair or table legs resulting from the misaligned joints cut on twisted stock. Flattening boards is, of course, one of a sequence of basic steps in creating a piece of furniture. Before you flatten stock, you must first rough cut it to length and width; after flattening, you need to reduce it to the desired thickness. Only then are you ready to cut and assemble the joints, fit doors and drawers, sand and finish the piece. 20 In this article we'll cover the essential, but too often overlooked task of flattening, and its Siamese twin, thicknessing (you almost never do the one without the other). Flattening requires more skill than thicknessing, but it is also far more critical. Only from an initial flat face can edges and ends be accurately squared. And it is only from a flat face that a uniform thickness and flat second face can be established. You can do both operations with just a hand plane, or you can save wear and tear on your muscles by employing a power jointer and power planer. They may not be the most exciting woodworking operations, but flattening and thicknessing are well worth taking time to master. Why Aren't Boards Flat To Begin With? Cut from the tree, boards inevitably cup across the width, bow along the length, or twist from end to end as their fibers redistribute internal tensions and shrink from moisture loss (Fig.l). It's easy to see that roughsawn boards need planing—undulations are likely to be more obvious and. at the very least, those sawmarks need to be removed. But many woodworkers buy boards that have already been surfaced, all too often assuming that the machine that cleaned and smoothed the surfaces also flattened the board. The fact is that simple planing machines are not designed to flatten boards, but merely to remove a uniform amount of wood from the faces. Heavy rollers positioned a few inches in front of and behind the cutterhead are powerful enough to press out most cupping, bowing or twisting in the short distance between rollers (Fig. 2). Once released from this pressure, however, the board resumes its previous shape—thinner, but still cupped, bowed or twisted. Some large mills employ machines designed to overcome this problem. Supported on a "floating" bed, the board passes over one cutterhead then, with the now flattened bottom face bearing on the planer table, under a second cutterhead that reduces its thickness. These boards are certainly flatter than those pushed through simple plan- How To Flatten ' Rough Stock by Roger Holmes |