Woodworker's Journal 1994-18-1, страница 19

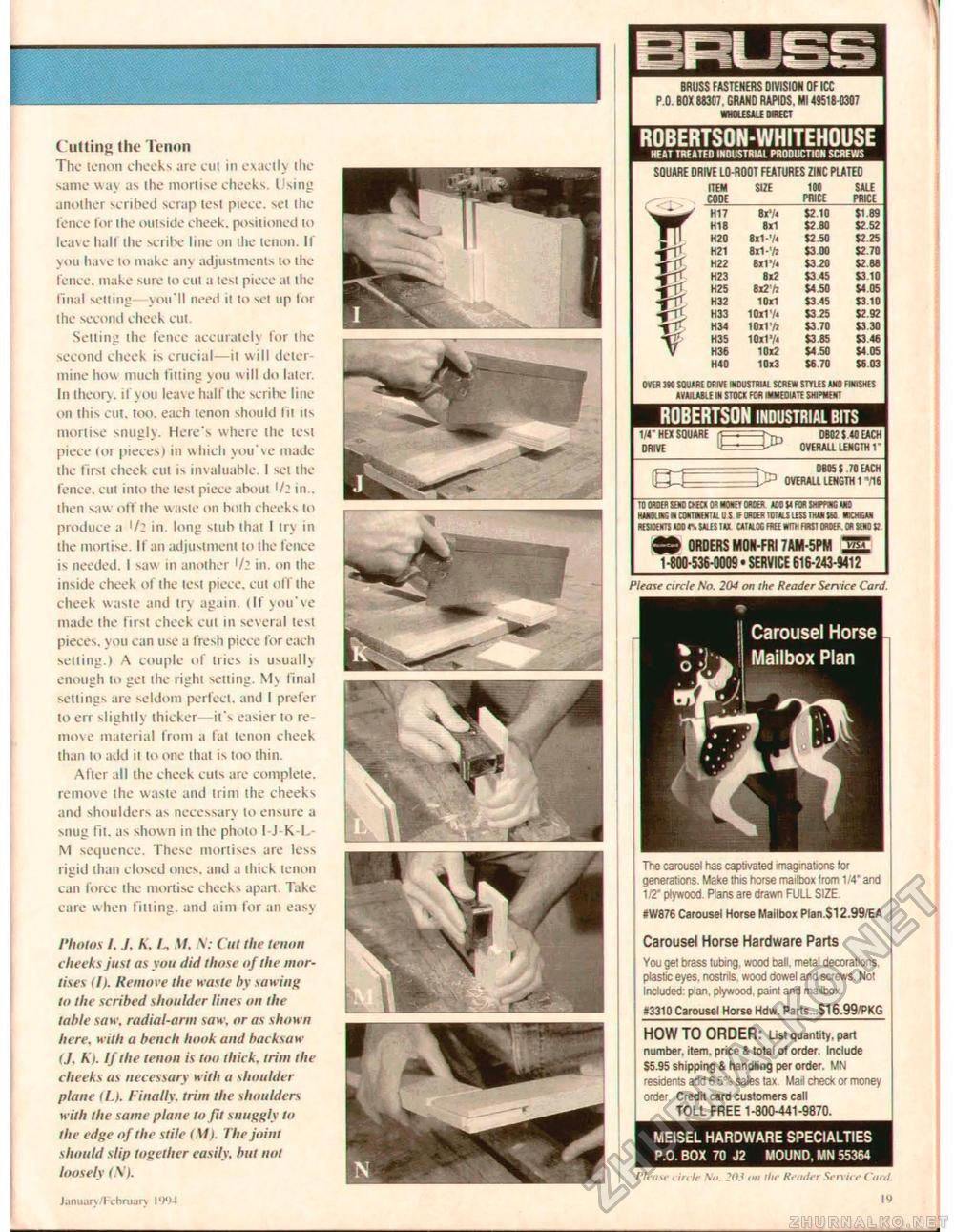

t utting the lenon The lenon cheeks are cut in exactly Ihe same way as the mortise checks. Using another scribed scrap lest piece, sei ihe fence for Ihe outside cheek, positioned to leave hall the scribe line on the lenon. It you have to make any adjustments to the fence, make sure to cut a test piece at the final setting—you'll need it to set up lor ihe second cheek cut. Setting the fence accurately lor ihe second cheek is crucial—il will determine how much tilting you will do later, in theory, if you leav e half the scribe line 011 this cut. too. each tenon should fit its mortise snugly. Here's where the tesi piece (or pieces) in which you've made the first cheek cut is invaluable. I set the fence, cut into the test piece a html '/; in., then saw off ihe wasle on both cheeks io produce a in. long siub that I try in the mortise. If an adjustment lo the fence is needed. I saw in another in. on (he inside cheek of ihe lest piece, cut oil the cheek wasle and try again, til you've made ihe first check cut in several lest pieces, you can use a fresh piece for each selling.> A couple of tries is usually enough lo gel the right setting. My final ■settings are seldom perfect, and I prefer to err slightly thicker—it's easier to remove material from a fat tenon cheek than to add it to one that is loo thin. Afler all the check cuts are complete, remove the wasle and trim ihe cheeks and shoulders as necessary to ensure a snug Fit, as show n in the photo I J K l_ M sequence. These mortises are less rigid than closed ones, and a thick tenon can force Ihe mortise cheeks apart. Take care when fitting, and aim for an easy Photos I. J, A. /„ M, N: Cut the tenon cheeks jus t as you did those of the mortises (I). Remove the waste by sawing to the scribed shoulder lines on the table saw, radial-arm saw. or as shown here, with a bench hook and hacksaw (J, A j. If the tenon is too thick, trim the cheeks as necessary with a shoulder plane tL). Finally, trim the shoulders with the same plane to fit snuggly to the edge of the stile (M). The joint should slip together easily, but not loosely IN). January/Fetalis rv t 'AM ROBERTSON-WHITEHOUSE HEAT TREATED INDUSTRIAL PDODUCTION SCREWS SQUARE DRIVE LO-ROOT FEATURES ZINC PLATED w a I SQUARE DRIVE LO-ROOT FEATURES ZINC PLATED

OVER 3M SQUARE DRIVE INDUSTRIAL SCREW STILES AND FINISHES AVAILABLE IN STOW FOR IMMEDIATE SHIPMENT OVER 3M SQUARE DRIVE INDUSTRIAL SCREW STILES AND FINISHES AVAILABLE IN STOW FOR IMMEDIATE SHIPMENT ROBERTSON industrial bits 1/4* HEX SQUARE DRIVE DBO?S M EACH OVERALL LENGTH 1" m 3> DBG5 S .70 EACH OVERALL LENGTH 1 716 TO ORDER SEND CHECK OR MONET ORDER ADC H FOR SwmW ANE Hindi II COKIIKKTAi U1 * ORDER TOTALS LEU THAN HO KSCHlSA* RESIDENTS ADD l\ SALES TAX CATALOG FREE WITH FIRST ORDER. OR SEND S2 ORDERS MOH-FRI7AM-5PM SE 1-800-536-0009 • SERVICE 618-243-3412 Please circle No. 204 on the Reader Service Card. Carousel Horse Mailbox Plan The carousel has captivated imaginations tor generations. Make this horse mailbox from 1/4" and 1/2' plywood. Plans are drawn FULL SIZE. *W876 Carousel Horse Mailbox Plan.S12.99/EA Carousel Horse Hardware Parts You get brass tubing, wood ball, metal decorations, plastic eyes, nostnls. wood dowel and screws. Nol Included: plan, plywood, paint and mailbox. #3310 Carousel Horse Hdw. Parts...S16.99/PKG HOW TO ORDER: List quantity, pad number, item, price & total of order. Include S5.95 shipping & handling per order. MM residents add 6.5% sales tax. Mail check or money order Credit card customers call TOLL FREE 1-800-441-9870. MEISEL HARDWARE SPECIALTIES P.O. BOX 70 J2 MOUND. MN 55364 Pleast" i irt le No. 203 on Ihe Reader Sen ice Card. 19 |