Woodworker's Journal 1994-18-1, страница 21

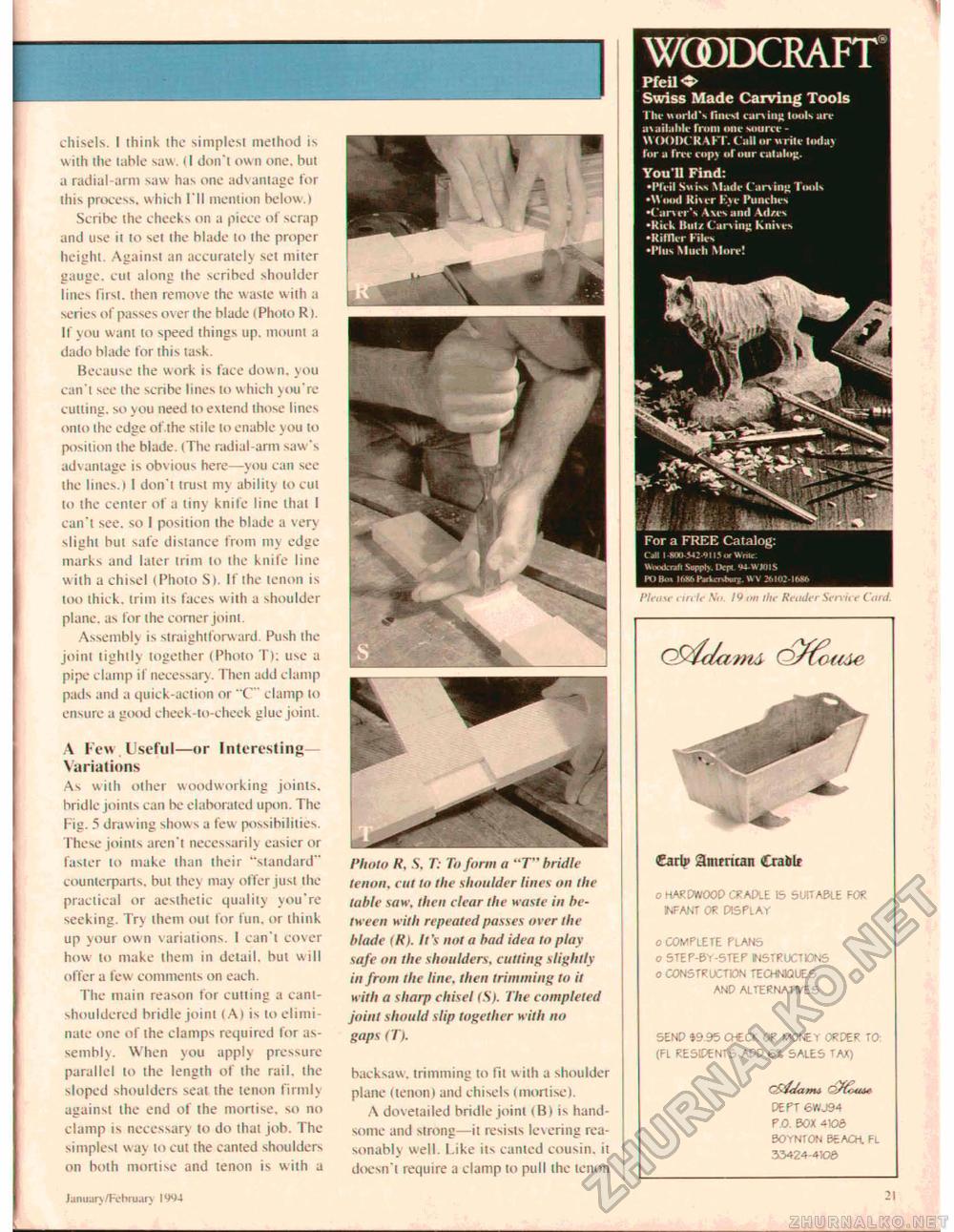

WOODCRAFT Pfeil^ Swiss Made Carving Tools Till' world's finest tan inn tools are available I'niiii one souree -WOODCRAFT. Call nr write today for a free eopj or our tal»lii[. You'll Find: •I'I'eil Swiss Made Carving Tools •Wood River Kyt Punches •Carver's Axes and Ad/is *Kiik Itul/ ('iinini; Knives •Hifller Files •Plus Mui'h More! chisels. I think the simplest method is wilh the table saw. (I don't own one. bui a radial-arm saw has one advantage for this process, which I'll mention below.) Scribe the cheeks on a piece of scrap and use it to set the blade to Ihe proper height. Against an accurately set miler gauge, cul along ihe scribed shoulder lines first, then remove the waste with a series of passes over the blade (Pholo R). It' you want to speed things up. mount a dado blade for this lask. Because the work is face down, you can't see the scribe lines to which you're cutting, so you need to extend those lines onto ihe edge of .the stile lo enable you to position ihe blade. (The radial arm saw's advantage is obvious here—you can see the lines.) I don't trust my ability to cut to the center of a liny knife line lhat I can't see. so I position the blade a very slight but safe disiance from my edge marks and later trim lo the knife line with a chisel (Photo S). If the lenon is too ihick. trim iis faces with a shoulder plane, as for ihe corner joint. Assembly is straightforward. Push ihe joini tightly together (Pholo T): use a pipe clamp if necessary. Then add clamp pads and a quick-action or "C" clamp to ensure a good cheek-to-cheek glue joint. A Few Useful—or Interesting Variations As with other woodworking joints, bridle joints can be elaborated upon. The Fig. 5 drawing shows a few possibilities. These joints aren't necessarily easier or faster lo make than their "standard" counterparts, but ihey may offer just ihe practical or aesthetic quality you're seeking. Try them oui for fun. or ihink up your own variations. I can't cover how to make them in detail, but will offer a few comments on each. The main reason for cutting a canl-shouldcred bridle joint (A) is lo eliminate one of the clamps required for assembly. When you apply pressure parallel lo the length of the rail, the sloped shoulders seal the tenon firmly against the end of the mortise, so no clamp is necessary 10 do thai job. The simplest way lo cut ihe canted shoulders on both mortise and tenon is with a Plea m' t in le Xh. 19 mi the Reader Semi e Card. Photo K. S. T: To form a "T" bridle tenon, cut to the shoulder lines on the table saw. then clear the waste in between wilh repeated passes over the blade (R). It's not a bad idea to play-safe on the shoulders, cutting slightly in from the line, then trimming to it with a sharp chisel <S). The completed joint should slip together with no gaps (T). backsavv. trimming lo fit wilh a shoulder plane (tenon) and chisels (mortise). A dovetailed bridle joint (B) is handsome and sirong—it resists levering reasonably well. I.ike its canted cousin, il doesn't require a clamp to pull the lenon QS^danu oJ&ute Carlp &mrrican trablr o hardwood cradle is suitable for INFANT OR DISPLAY o COMPLETE PLANS o STEP-0Y-5TEP INSTRUCTIONS o CONSTRUCTION TECHNIQUES AND ALTERNATES SEND 49.95 CHECK OF MOf€> ORDER TO' (FL RESIDENTS ADD 6% SALES TAX) GS&ilJWJ d^&UM DEPT 6WJ94 P.O. POX 410fl BOYNTON BE.ACH, FL 33424-4100 For a FREE Catalog: Call l-tmo-MI-'illSwWnie: Woodcraft Sopplv. Dc[» W-WJOIS PO But I MM) PirUT.ts.rf. WV 2tilOM<>» JanuarVFebruarv 1W4 |