Woodworker's Journal 1994-18-1, страница 24

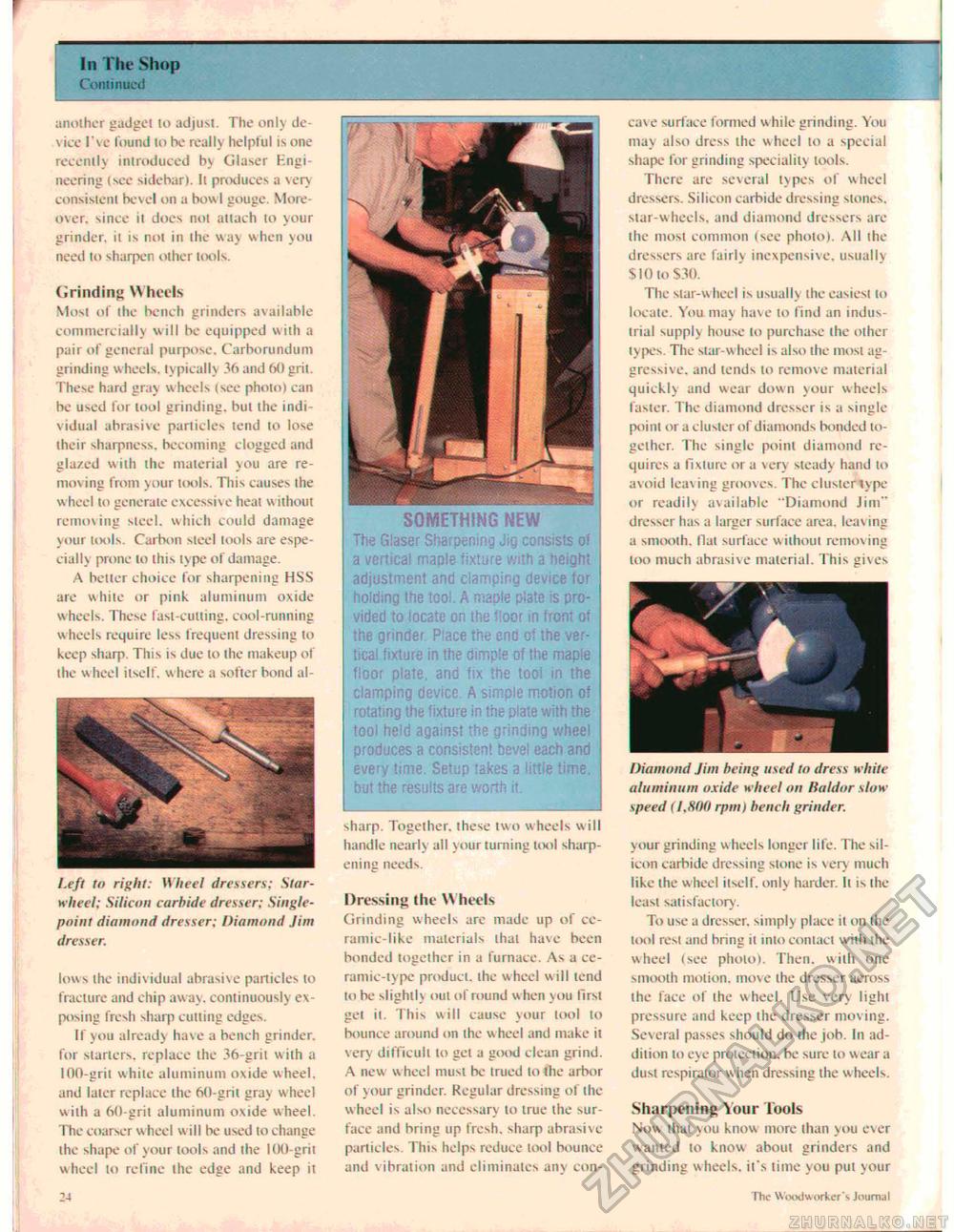

In The Shop Continued another gadget to adjust. The only device I've found to he really helpful is one recently introduced by Glaser Kngi-necring (see sidebar). It produces a very consistent bevel on a bowl gouge. Moreover. since it does not attach to your grinder, it is not in the way when you need to sharpen other tools. Grinding Wheels Most of the bench grinders available commercially will be equipped with a pair of general purpose. Carborundum grinding wheels, typically 3b and 60 grit. These hard gray wheels (see photo) can be used for tool grinding, but the indi vidua) abrasive particles tend to lose their sharpness, becoming clogged and glazed with the material you are removing from your tools. This causes the wheel to generate excessive heat without rcrnov ing steel, which could damage your twls. Carbon steel tools are especially prone to this type of damage. A better choice for sharpening HSS are while or pink aluminum oxide wheels. These fast-cutting, cool-running wheels require less frequent dressing to keep sharp. This is due to the makeup of the wheel itself, w here a softer bond af- Left to right: W heel dressers; Star-wheel; Silicon carbide dresser: Single-point diamond dresser; Diamond Jim dresser. lows the individual abrasive particles to fracture and chip away, continuously exposing fresh sharp cutting edges. If you already have a bench grinder, for starters, replace the 36-grit w ith a 100-grii white aluminum oxide wheel, and later replace the 60-grit gray wheel with a 60-grit aluminum oxide wheel. The coarser wheel w ill be used to change the shape of your tools and the 100-grit wheel to refine the edge and keep it SOMETHING MEW The Glaser Sharpening Jig consists of a vertical maple fixture with a height adjustment and clampina device for holding the tool. A maple plate is provided to locate on the floor in front of the grinder. Piace the end of the vertical fixture in the dimple of fife maple floor plate, and fix the tool in the clamping device. A simple motion of rotating Ihe fixture in the plate with the tool held against the grinding wheel produces a consistent bevel each and every time. Setup takes a little time, but the results are worth it. sharp. Together, these two w heels w ill handle nearly all your turning tool sharpening needs. Dressing the W heels Grinding wheels arc made up of ceramic-like materials that have been bonded together in a furnace. As a ceramic-type product, ihe wheel will tend lo be slightly out of round when you first gel i(. This will cause your tool lo bounce around on the wheel and make il very difficult lo gel a good clean grind. A new wheel musi be trued lo Ihe arbor of your grinder. Regular dressing of the wheel is also necessary lo irue the surface and bring up fresh, sharp abrasive particles. This helps reduce tool bounce and vibration and eliminates anv con cave surface formed while grinding. You may also dress the w heel to a special shape for grinding speciality tools. There are several lypes of wheel dressers. Silicon carbide dressing stones, star-wheels, and diamond dressers are the most common (see photo). All the dressers arc fairly inexpensive, usually $10 to $30. The siar-w heel is usually the easiesi to locale. You may have to find an industrial supply house to purchase (he olhcr lypes. The star-wheel is also ihe most aggressive. and lends lo remove material quickly and wear down your wheels faster. The diamond dresser is a single point or a cluster of diamonds bonded together. The single point diamond requires a fixture or a very steady hand lo avoid leav ing grooves. The cluslertype or readily available "Diamond Jim" dresser has a larger surface area, leaving a smooth, flat surface wiihoui remov ing loo much abrasive material. This gives Diamond Jim being used to dress white aluminum oxide wheel on llaldor slow speed (1,800 rpml bench grinder. your grinding wheels longer life. The silicon carbide dressing stone is very much like the w heel itself, only harder. It is the least satisfactory. To use a dresser, simply place it on the tool rest and bring il inlo contact with the wheel (see pholo). Then, wilh one smooth motion, move the dresser across the face of the w heel. Use very light pressure and keep the dresser moving. Several passes should do the job. In addition to eye protection, be sure to wear a dust respirator when dressing the wheels. Sharpening Your lools Now dial you know more ilian you ever wanted to know about grinders and grinding wheels, it's time you pui your .">8 The Woodworker's Journal |