Woodworker's Journal 1994-18-6, страница 75

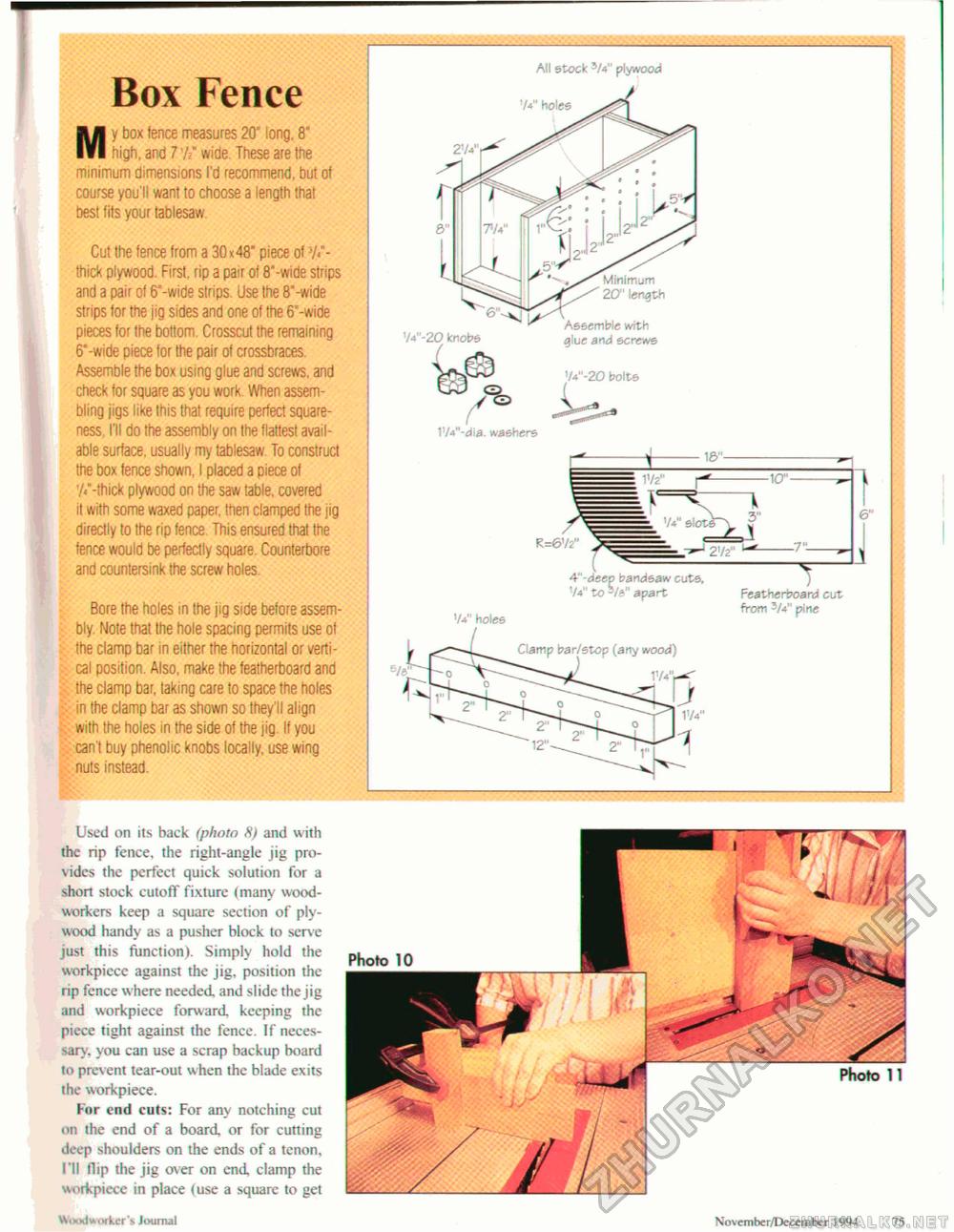

Box Fence My box fence measures 20" long. 8* high, and VI* wide. These are the minimum dimensions I'd recommend, but of course you'li want to choose a length that best fits your tablesaw. Cut the fence from a 30*48" piece of V-thick plywood. First, rip a pair of 8"-wide strips and a pair of 6"-wide strips. Use the 8"-wide strips tor the jig sides and one of the 6"-wide pieces for the bottom. Crosscut the remaining 6"-wide piece for the pair of crossbraces. Assemble the box using glue and screws, and check for square as you work. When assembling jigs like this that require perfect squareness, I'll do the assembly on the flattest available surface, usually my tablesaw. To construct the box fence shown, I placed a piece of 'A'-thick plywood on the saw table, covered it with some waxed paper, then clamped the jig directly to the rip fence. This ensured that the fence would be perfectly square. Counterbore and countersink the screw holes. Bore the holes in the jig side before assembly. Note that the hole spacing permits use of the clamp bar in either the horizontal or vertical position. Also, make the featherboard and the clamp bar, taking care to space the holes in the clamp bar as shown so they'll align with the holes in the side of the jig. If you can't buy phenolic knobs locally, use wing nuts instead. All stock 3/4" plywood V4" holes '/4"-2O knobs Minimum 20" length Assemble with glue and screws VV-20 bolts / VU"-d\a. washers R=6'/2" -10"- 6" 2'/2" ^-7 - 4"-deep bandeaw cuts, '/■»" to =/e" apart Clamp bar/stop (any wood) - Featherboard cut from 3/4" pine Used on its back (photo ft) and with the rip fence, the right-angle jig provides the perfect quick solution for a short stock cutoff fixture (many woodworkers keep a square section of plywood handy as a pusher block to serve just this function). Simply hold the workpiece against the jig, position the rip fence where needed, and slide the jig and workpiece forward, keeping the piece tight against the fence. If necessary. you can use a scrap backup board to prevent tear-out when the blade exits the workpiece. For end cuts: For any notching cut on the end of a board, or for cutting deep shoulders on the ends of a tenon. I'll flip the jig over on end, clamp the workpiece in place (use a square to get Photo 10 Woodwoder's Journal Movember/Decembcr 1994 75 |