Woodworker's Journal 1994-18-6, страница 73

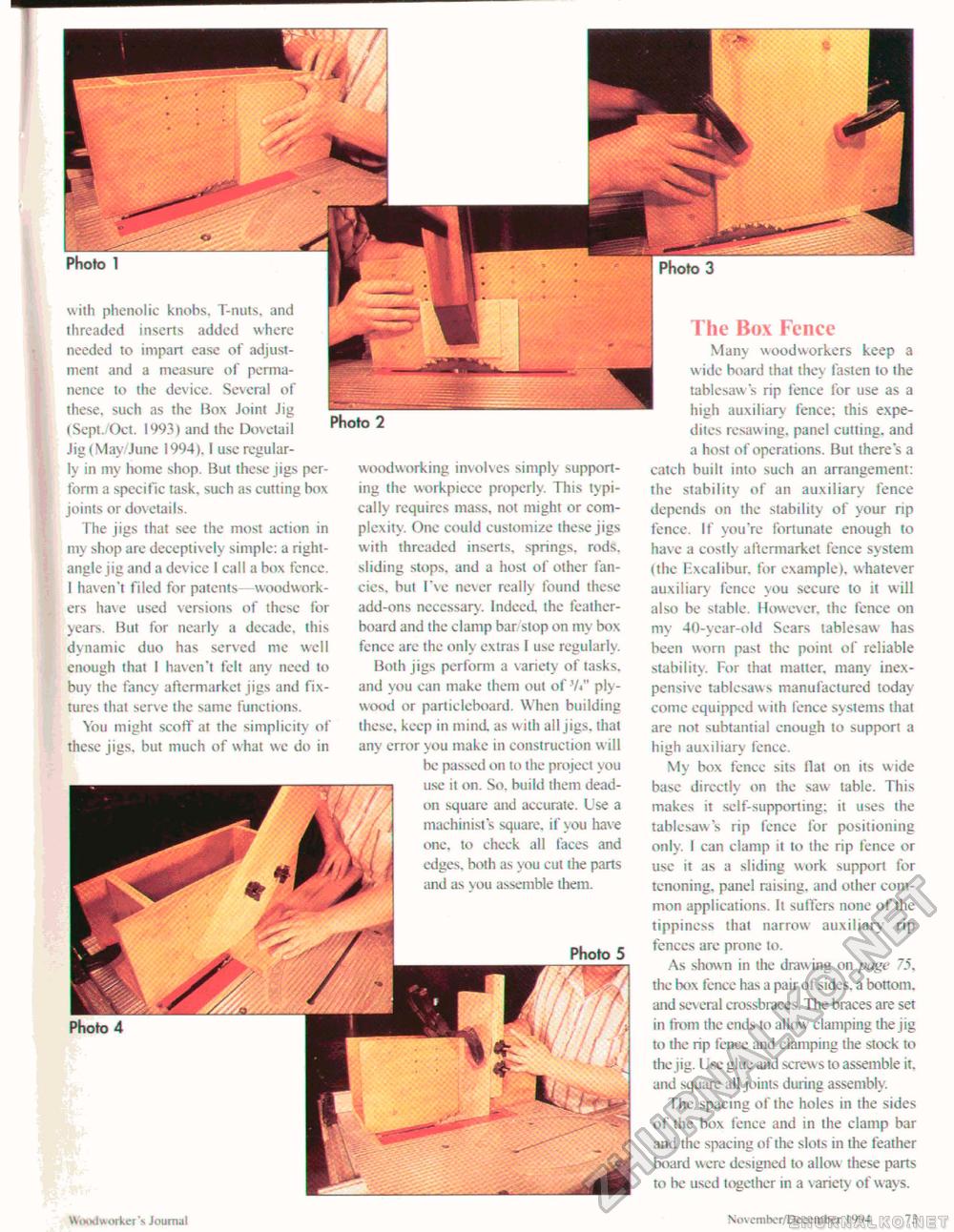

Photo 1 Photo 3 The Box Fence Many woodworkers keep a wide hoard that they fasten to the tablesaw s rip fence ibr use as a high auxiliary fence; this expedites rcsawing, panel cutting, and a host of operations. But there's a catch built into such an arrangement: the stability of an auxiliary fence depends on the stability of your rip fence. If you're fortunate enough to have a costly aftcrmarket fence system (the Excalibur. for example), whatever auxiliary fcncc you secure to it will also be stable. However, the fence on my 40-year-old Sears tablesaw has been worn past the point of reliable stability. For that matter, many inexpensive tablcsaws manufactured today come equipped with fence systems that are not subtantial enough to support a high auxiliary fence. My box fcncc sits flat on its wide base dircctly on the saw table. This makes it self-supporting; it uses the tablesaw's rip fence for positioning only. I can clamp it to the rip fence or use it as a sliding work support for tenoning, panel raising, and other common applications. It suffers none of the tippiness that narrow auxiliary rip fences are prone to. As shown in the drawing on page 75, the box fence has a pair of sides, a bottom, and several crossbraces. The braces are set in from the ends to allow clamping the jig to the rip fence and clamping the stock to the jig. Use glue and screws to assemble it. and square all joints during assembly. The spacing of the holes in the sides of the box fence and in the clamp bar and the spacing of the slots in the feather board were designed to allow these parts to be used together in a variety of ways. with phenolic knobs, T-nuts, and threaded inserts added where needed to impart ease of adjustment and a measure of permanence to the device. Several of these, such as the Box Joint Jig (Sept./Oct. 1993) and the Dovetail Jig (May/June 1994). I use regularly in my home shop. But these jigs perform a specific task, such as cutting box joints or dovetails. The jigs that see the most action in my shop are deceptively simple: a right-angle jig and a device I call a box fence. I haven't filed for patents—woodworkers have used versions of these for years. But for nearly a decade, this dynamic duo has served me well enough that 1 haven't felt any need to buy the fancy aftcrmarket jigs and fixtures that serve the same functions. You might scoff at the simplicity of these jigs, but much of what we do in Photo 2 woodworking involves simply supporting the workpiecc properly. This typically requires mass, not might or complexity. One could customize these jigs with threaded inserts, springs, rods, sliding stops, and a host of other fancies, but I've never really found these add-ons necessary. Indeed the leather-board and the clamp bar stop on my box fence are the only extras I use regularly. Both jigs perform a variety of tasks, and you can make them out of V«" plywood or particleboard. When building these, keep in mind as with all jigs, that any error you make in construction will be passed on to the project you use it on. So, build them dead-on square and accurate. Use a machinist's square, if you have one, to check all faces and edges, both as you cut the parts and as vou assemble them. Photo 5 Photo 4 Woodworker s Journal Novembcr/December 1994 1<1 |