Woodworker's Journal 1994-18-6, страница 72

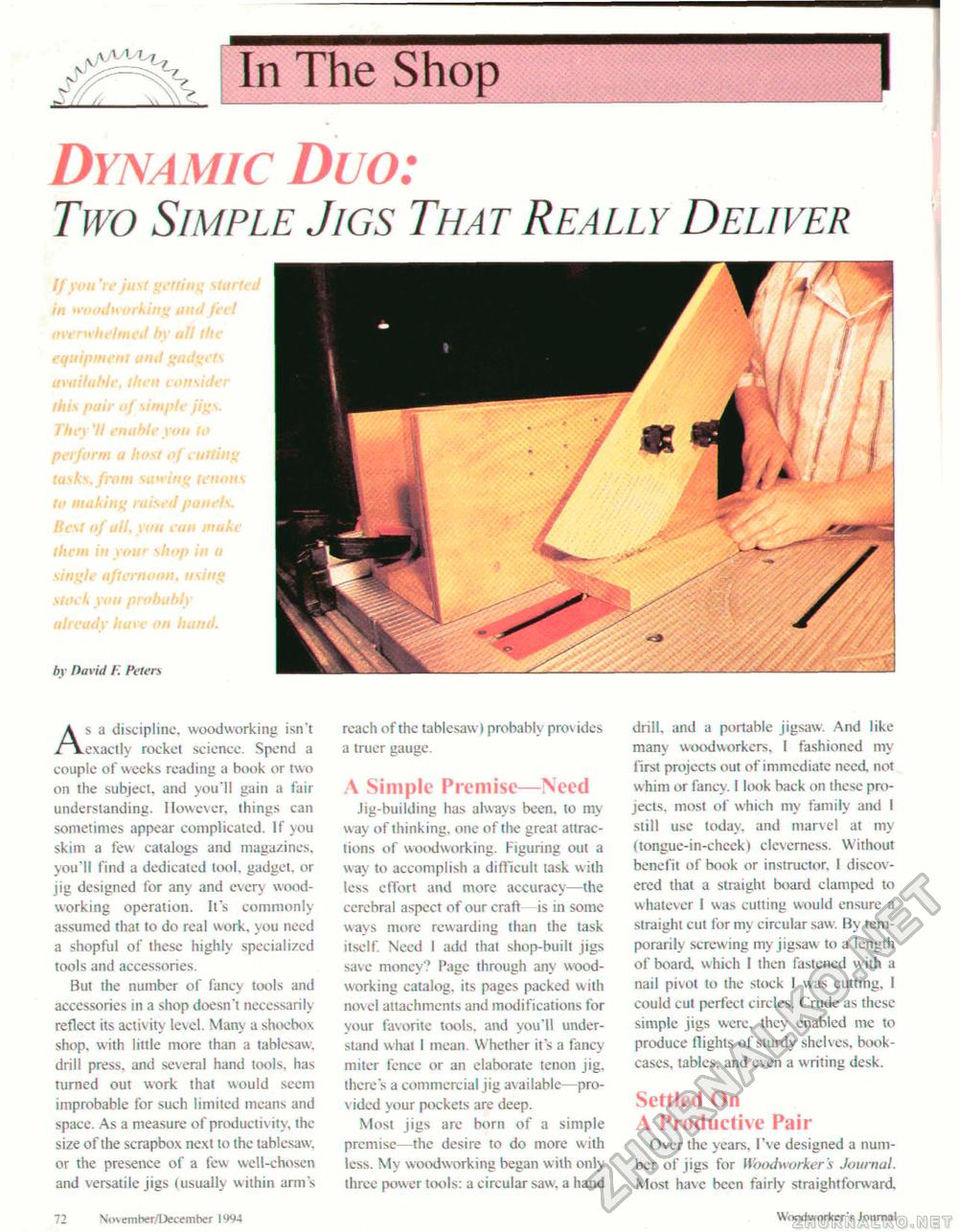

In The Shop I - ' " ' ■ '-■ »-----------:----------------- Dynamic Duo:Two Simple Jigs That Really Deliver If yon 're just getting started in wm/mwAing and feel overwhelmed by all the equipment and gadgets available, then consider this pair of simple jigs. They'll enable you to perform a h ost of cutting tasks, from sawing tenons to making raised panels. Best of all, you con make them in your shop in a single afternoon, using stock you probably already have on hand. by David F. Peters As a discipline, woodworking isn't exactly rocket science. Spend a couple of weeks reading a book or two on the subject, and you'll gain a fair understanding. However, things can sometimes appear complicated. If you skim a few catalogs and magazines, you'll find a dedicated tool, gadget, or jig designed for any and every woodworking operation. It's commonly assumed that to do real work, you need a shopful of these highly specialized tools and accessories. But the number of fancy tools and accessories in a shop doesn't necessarily reflect its activ ity level. Many a shoebox shop, with little more than a tablesaw, drill press, and several hand tools, has turned out work that would seem improbable for such limited means and space. As a measure of productivity, the size of the scrapbox next to the tablesaw, or the presence ol" a few well-chosen and versatile jigs (usually within arm's 72 Novemher/December 1994 reach of the tablesaw ) probably prov ides a truer gauge. A Simple Premise—Need Jig-building has always been, to my way of thinking, one of the great attractions of woodworking. Figuring out a way to accomplish a difficult task with less effort and more accuracy—the cerebral aspect of our craft is in some ways more rewarding than the task itself. Need I add that shop-built jigs save money? Page through any woodworking catalog, its pages packed with novel attachments and modifications for your favorite tools, and you'll understand what I mean. Whether it's a fancy miter fence or an elaborate tenon jig. there's a commercial jig available—provided your pockets are deep. Most jigs are born of a simple premise—the desire to do more with less. My woodworking began with only three power tools: a circular saw. a hand drill, and a portable jigsaw. And like many woodworkers, I fashioned my first projects out of immediate need, not whim or fancy. I look back on these projects, most of which my family and I still use today, and marvel at my (tongue-in-cheek) cleverness. Without benefit of book or instructor, I discovered that a straight board clamped to whatever I was cutting would ensure a straight cut for my circular saw. By temporarily screwing my jigsaw to a length of board which I then fastened with a nail pivot to the stock I was cutting. I could cut perfect circles. Crude as these simple jigs were, they enabled me to produce flights of sturdy shelves, bookcases, tables, and even a writing desk. Settled On A Productive Pair Over the years. I've designed a number of jigs for Woodworker's Journal. Most have been fairly straightforward Wixxiworkcr's Journal |