Woodworker's Journal 2001-25-1, страница 31

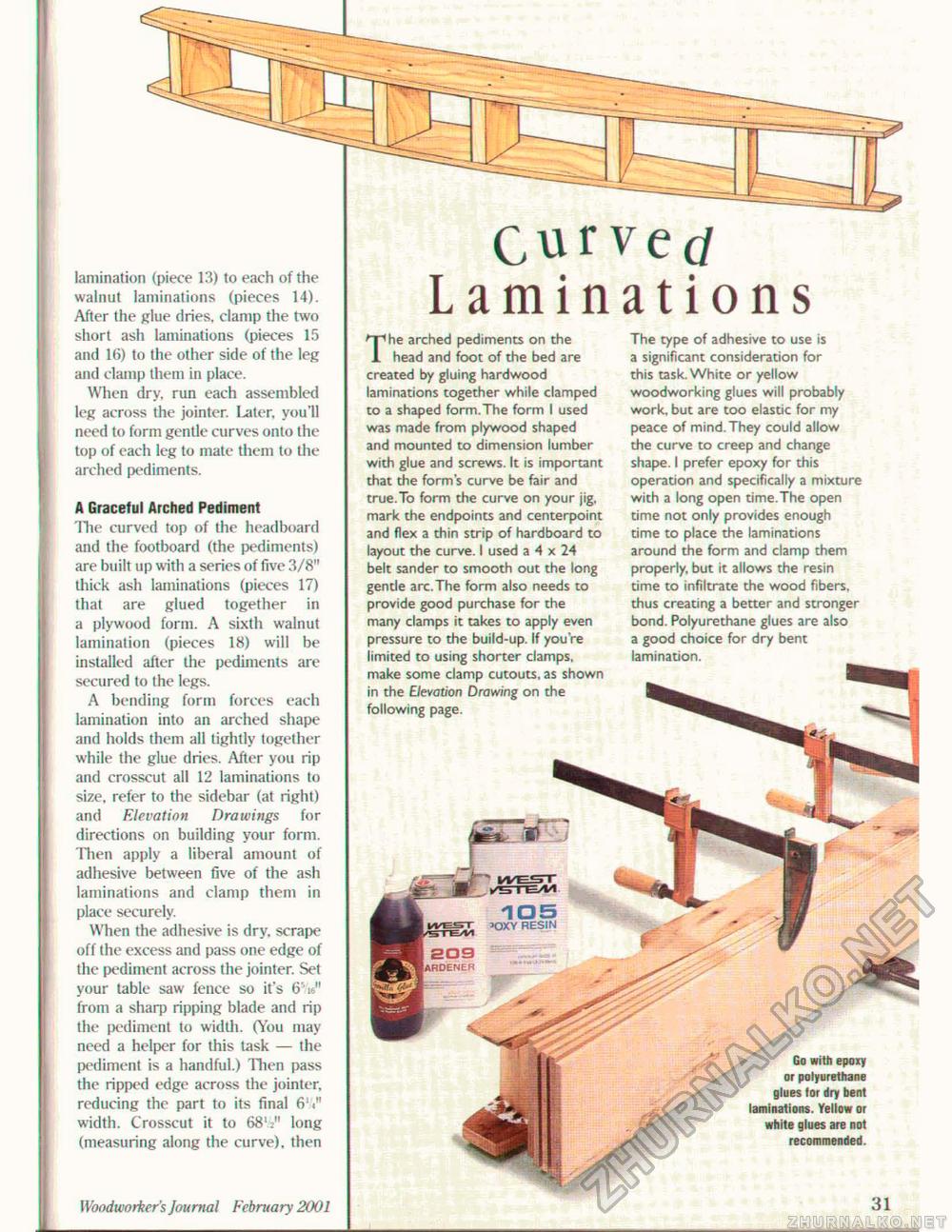

Curved Laminationslamination (piece 13) to each of the walnut laminations (pieces 14). After the glue fines, clamp the two short ash laminations (pieces 15 and 16) to the other side of the leg and clamp them in place. When dry, run each assembled leg across the jointer. Later, you'll need to form gentle curves onto the top of each leg to mate them to the arched pediments. A Graceful Arched Pediment The curved top of the headboard and the footboard (the pediments) are built up with a series of five 3/8" thick ash laminations (pieces 17) that are glued together in a plywood form. A sixth walnut lamination (pieces 18) will be installed after the pediments are secured to the legs. A bending form forces each lamination into an arched shape and holds them all tightly together while the glue dries. After you rip and crosscut all 12 laminations to size, refer to the sidebar (at right) and Elevation Drawings for directions on building your form. Then apply a liberal amount of adhesive between five of the ash laminations and clamp them in place securely. When the adhesive is dry. scrape off the excess and pass one edge of the pediment across the jointer. Set your table saw fence so it's 65u>M from a sharp ripping blade and rip the pediment lo width. (You may need a helper for this task — the pediment is a handful.) Then pass the ripped edge across the jointer, reducing the part to its final 61/' width. Crosscut it to 68'2" long (measuring along the curve), then The arched pediments on the head and foot of the bed are created by gluing hardwood laminations together while clamped to a shaped form.The form I used was made from plywood shaped and mounted to dimension lumber with glue and screws. It is important that the form's curve be fair and true.To form the curve on your jig, mark the endpoints and centerpoint and flex a thin strip of hardboard to layout the curve. I used a 4 x 24 belt sander to smooth out the long gentle arc,The form also needs to provide good purchase for the many clamps it takes to apply even pressure to the build-up. If you're limited to using shorter clamps, make some clamp cutouts, as shown in the Elevation Drawing on the following page. The type of adhesive to use is a significant consideration for this task. White or yellow woodworking glues will probably work, but are too elastic for my peace of mind. They could allow the curve to creep and change shape. I prefer epoxy for this operation and specifically a mixture with a long open time.The open time not only provides enough time to place the laminations around the form and clamp them properly, but it allows the resin time to infiltrate the wood fibers, thus creating a better and stronger bond. Polyurethane glues are also a good choice for dry bent lamination. Go with epoxy or polyurethane glues tor dry bent laminations. Yellow or white glues are not recommended. Woodworker's Journal February 2001 31 |