Woodworker's Journal 2006-30-2, страница 30

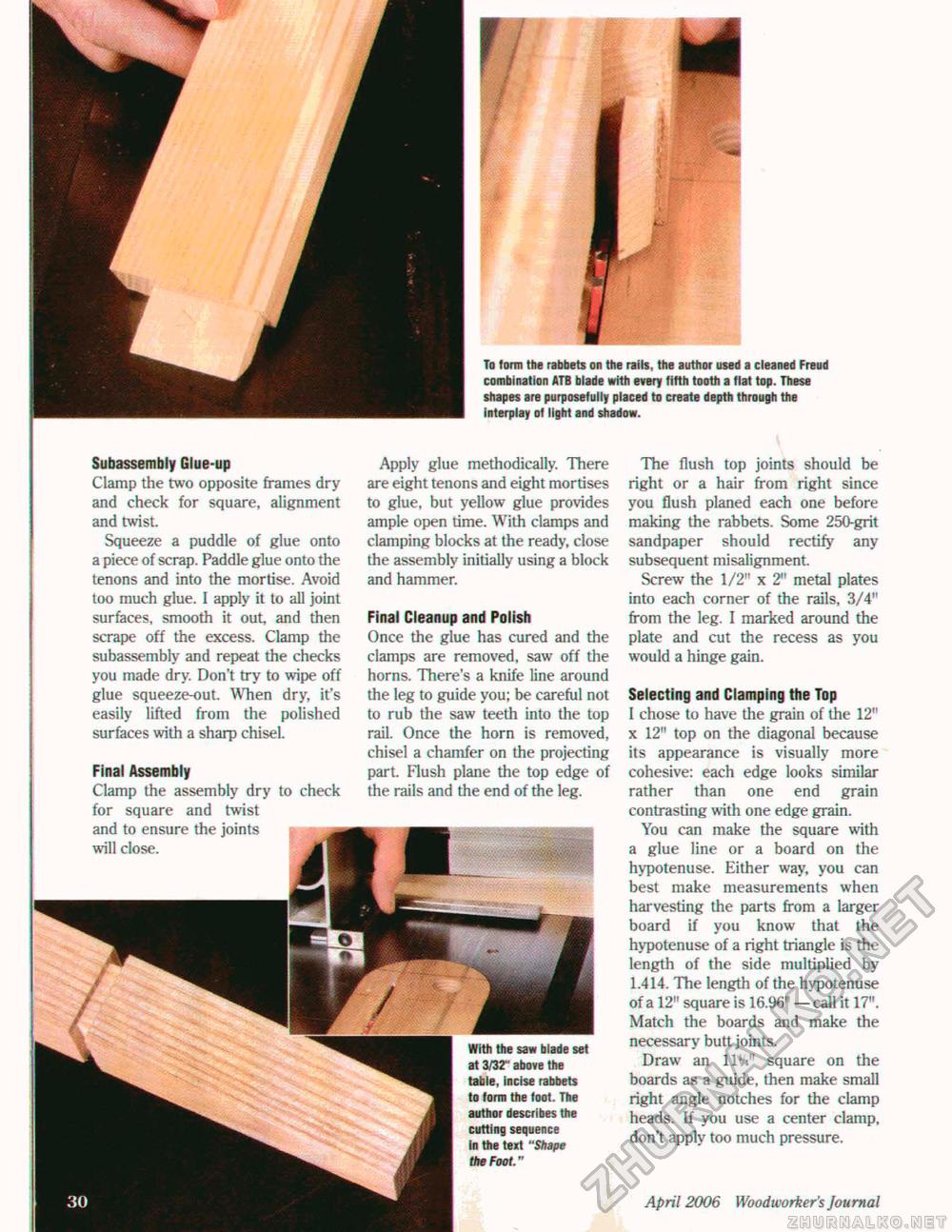

The flush top joints should be right or a hair from right since you flush planed each one before making the rabbets. Some 250-grit sandpaper should rectify any subsequent misalignment. Screw the 1/2" x 2" metal plates into each corner of the rails, 3/4" from the leg. I marked around the plate and cut the recess as you would a hinge gain. Apply glue methodically. There are eight tenons and eight mortises to glue, but yellow glue provides ample open time. With clamps and clamping blocks at the ready, close the assembly initially using a block and hammer. Final Cleanup and Polish Once the glue has cured and the clamps are removed, saw off the horns. There's a knife line around the leg to guide you; be careful not to rub the saw teeth into the top rail. Once the horn is removed, chisel a chamfer on the projecting part. Flush plane the top edge of the rails and the end of the leg. With the saw blade set at 3/32" above the table, incise rabbets to form the foot. The author describes the cutting sequence In the text "Shape the Foot." Subassembly Glue-up Clamp the two opposite frames dry and check for square, alignment and twist. Squeeze a puddle of glue onto a piece of scrap. Paddle glue onto the tenons and into the mortise. Avoid too much glue. I apply it to all joint surfaces, smooth it out, and then scrape off the excess. Clamp the subassembly and repeat the checks you made dry. Don't try to wipe off glue squeeze-out When dry, it's easily lifted from the polished surfaces with a sharp chisel. Final Assembly Clamp the assembly dry to check for square and twist and to ensure the joints will close. Selecting and Clamping the Top I chose to have the grain of the 12" x 12" top on the diagonal because its appearance is visually more cohesive: each edge looks similar rather than one end grain contrasting with one edge grain. You can make the square with a glue line or a board on the hypotenuse. Either way, you can best make measurements when harvesting the parts from a larger board if you know that the hypotenuse of a right triangle is the length of the side multiplied by 1.414. The length of the hypotenuse of a 12" square is 16.96" — call it 17". Match the boards and make the necessary butt joints. Draw an ll1/ square on the boards as a guide, then make small right angle notches for the clamp heads. If you use a center clamp, don't apply too much pressure. 30 April 2006 Woodworker's Journal |