Woodworker's Journal 2006-30-5, страница 38

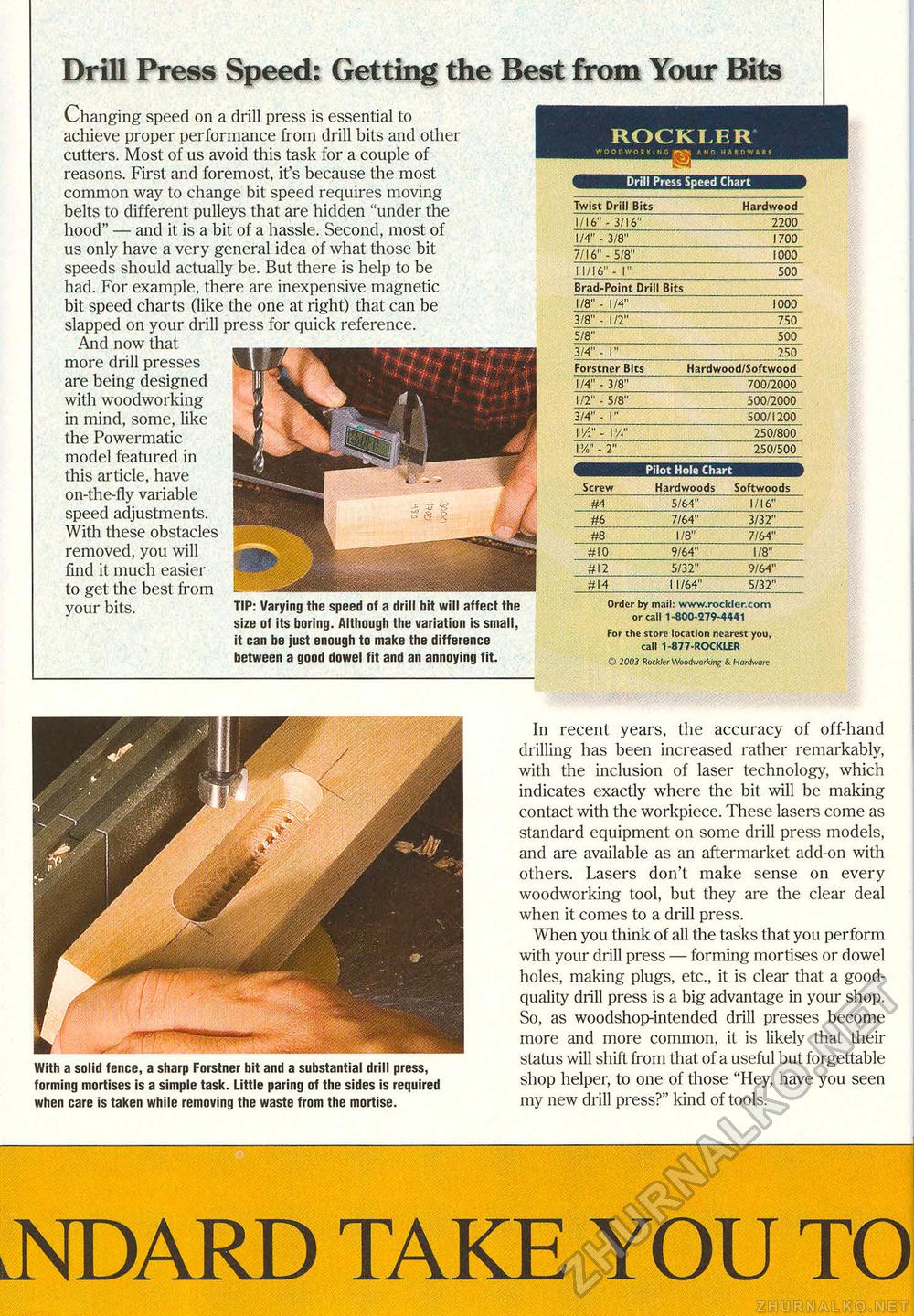

Drill Press Speed: Getting the Best from Your Bits Prill Press Speed Chart Pilot Hole Chart Changing speed on a drill press is essential to achieve proper performance from drill bits and other cutters. Most of us avoid this task for a couple of reasons. First and foremost, it's because the most common way to change bit speed requires moving belts to different pulleys that are hidden "under the hood" — and it is a bit of a hassle. Second, most of us only have a very general idea of what those bit speeds should actually be. But there is help to be had. For example, there are inexpensive magnetic bit speed charts (like the one at right) that can be slapped on your drill press for quick reference. And now that more drill presses are being designed with woodworking in mind, some, like the Powermatic model featured in this article, have on-the-fly variable speed adjustments. With these obstacles removed, you will find it much easier to get the best from your bits. T,P: Varying the speed of a size of its boring. Although the variation is small, it can be just enough to make the difference between a good dowel fit and an annoying fit. Screw Hardwoods Softwoods #4___5/64" 1/16" #6 _____ " 7/64"__3/32"" ~#8 "" "1/8" 7/64" # 10 " 9/64"__"l/8" "#I2"______ 5/32" _ 9/64" #14 _ 11/64" 5/32" Order by mail: www.rockler.com or call 1-800-279-4441 For the store location nearest you, call 1 -877-ROCKLER © 2003 Rockier Woodworking & Hardware Hardwood I/2" - 5/8" 500/2000 3/4"- I" 500/i200 11/2" - I 'A" 250/800 l3/s"-2" 250/500 ___________________250 Forstner Bits__Hardwood/Softwood I/4" - 3/8" ""706/2000 With a solid fence, a sharp Forstner bit and a substantial drill press, forming mortises is a simple task. Little paring of the sides is required when care is taken while removing the waste from the mortise. In recent years, the accuracy of off-hand drilling has been increased rather remarkably, with the inclusion of laser technology, which indicates exactly where the bit will be making contact with the workpiece. These lasers come as standard equipment on some drill press models, and are available as an aftermarket add-on with others. Lasers don't make sense on every woodworking tool, but they are the clear deal when it comes to a drill press. When you think of all the tasks that you perform with your drill press — forming mortises or dowel holes, making plugs, etc., it is clear that a good-quality drill press is a big advantage in your shop. So, as woodshop-intended drill presses become more and more common, it is likely that their status will shift from that of a useful but forgettable shop helper, to one of those "Hey, have you seen my new drill press?" kind of tools. lNDARD take you to |