Woodworker's Journal 2006-30-5, страница 39

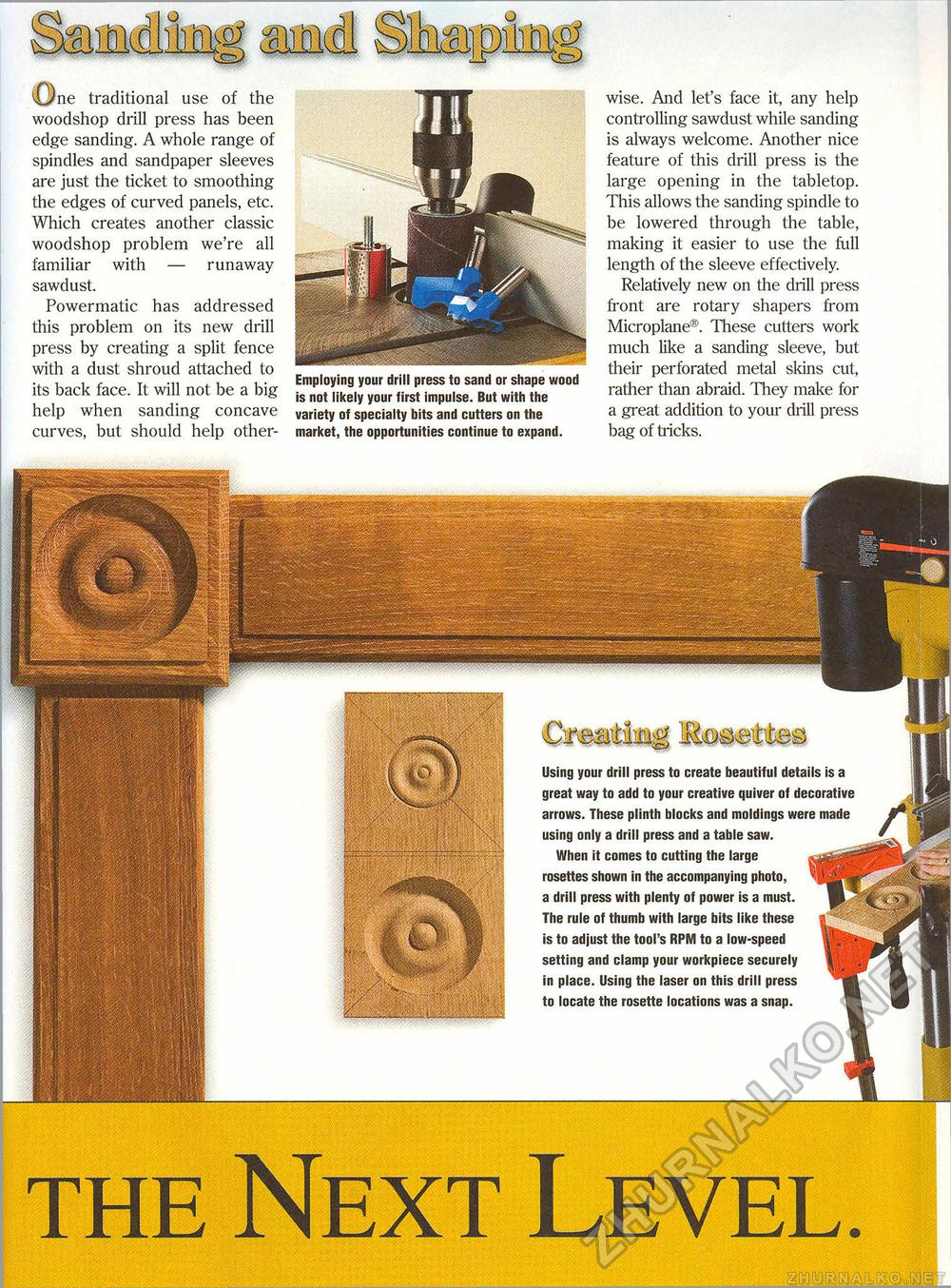

C/ne traditional use of the woodshop drill press has been edge sanding. A whole range of spindles and sandpaper sleeves are just the ticket to smoothing the edges of curved panels, etc. Which creates another classic woodshop problem we're all familiar with — runaway sawdust. Powermatic has addressed this problem on its new drill press by creating a split fence with a dust shroud attached to its back face. It will not be a big help when sanding concave curves, but should help other- Employing your drill press to sand or shape wood is not likely your first impulse. But with the variety of specialty bits and cutters on the market, the opportunities continue to expand. wise. And let's face it, any help controlling sawdust while sanding is always welcome. Another nice feature of this drill press is the large opening in the tabletop. This allows the sanding spindle to be lowered through the table, making it easier to use the full length of the sleeve effectively. Relatively new on the drill press front are rotary shapers from Microplane®. These cutters work much like a sanding sleeve, but their perforated metal skins cut, rather than abraid. They make for a great addition to your drill press bag of tricks. Using your drill press to create beautiful details is a great way to add to your creative quiver of decorative arrows. These plinth blocks and moldings were made using only a drill press and a table saw. When it comes to cutting the large gig rosettes shown in the accompanying photo, v ^ % a drill press with plenty of power is a must. The rule of thumb with large bits like these f is to adjust the tool's RPM to a low-speed setting and clamp your workpiece securely f.^: in place. Using the laser on this drill press to locate the rosette locations was a snap. the Next Level. |