Woodworker's Journal 2006-30-5, страница 40

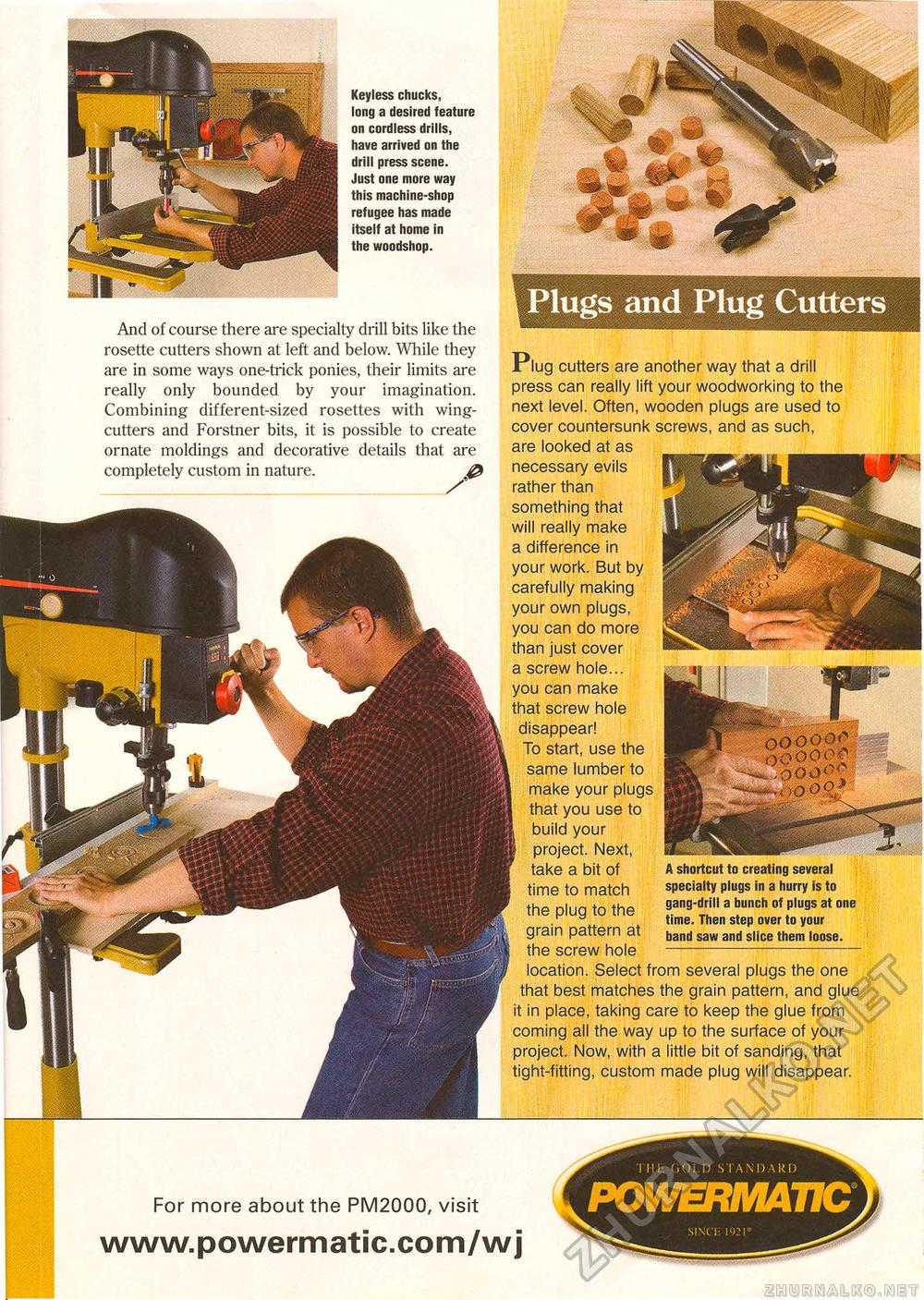

OOOOO^ T OOOOOO Plugs and Plug Cutters iltsiliSHH Plug cutters are another way that a drill press can really lift your woodworking to the next level. Often, wooden plugs are used to cover countersunk screws, and as such, are looked at as necessary evils rather than something that will really make a difference in your work. But by carefully making your own plugs, you can do more than just cover a screw hole... you can make that screw hole disappear! To start, use the same lumber to make your plugs that you use to build your project. Next, take a bit of time to match the plug to the grain pattern at the screw hole-- location. Select from several plugs the one that best matches the grain pattern, and glue it in place, taking care to keep the glue from coming all the way up to the surface of your project. Now, with a little bit of sanding, that tight-fitting, custom made plug will disappear. A shortcut to creating several specialty plugs in a hurry is to gang-drill a bunch of plugs at one time. Then step over to your band saw and slice them loose. For more about the PM2000, visit Keyless chucks, long a desired feature on cordless drills, have arrived on the drill press scene. Just one more way this machine-shop refugee has made itself at home in the woodshop. And of course there are specialty drill bits like the rosette cutters shown at left and below. While they are in some ways one-trick ponies, their limits are really only bounded by your imagination. Combining different-sized rosettes with wing-cutters and Forstner bits, it is possible to create ornate moldings and decorative details that are completely custom in nature. |

|||||||||