Woodworker's Journal 2006-30-5, страница 37

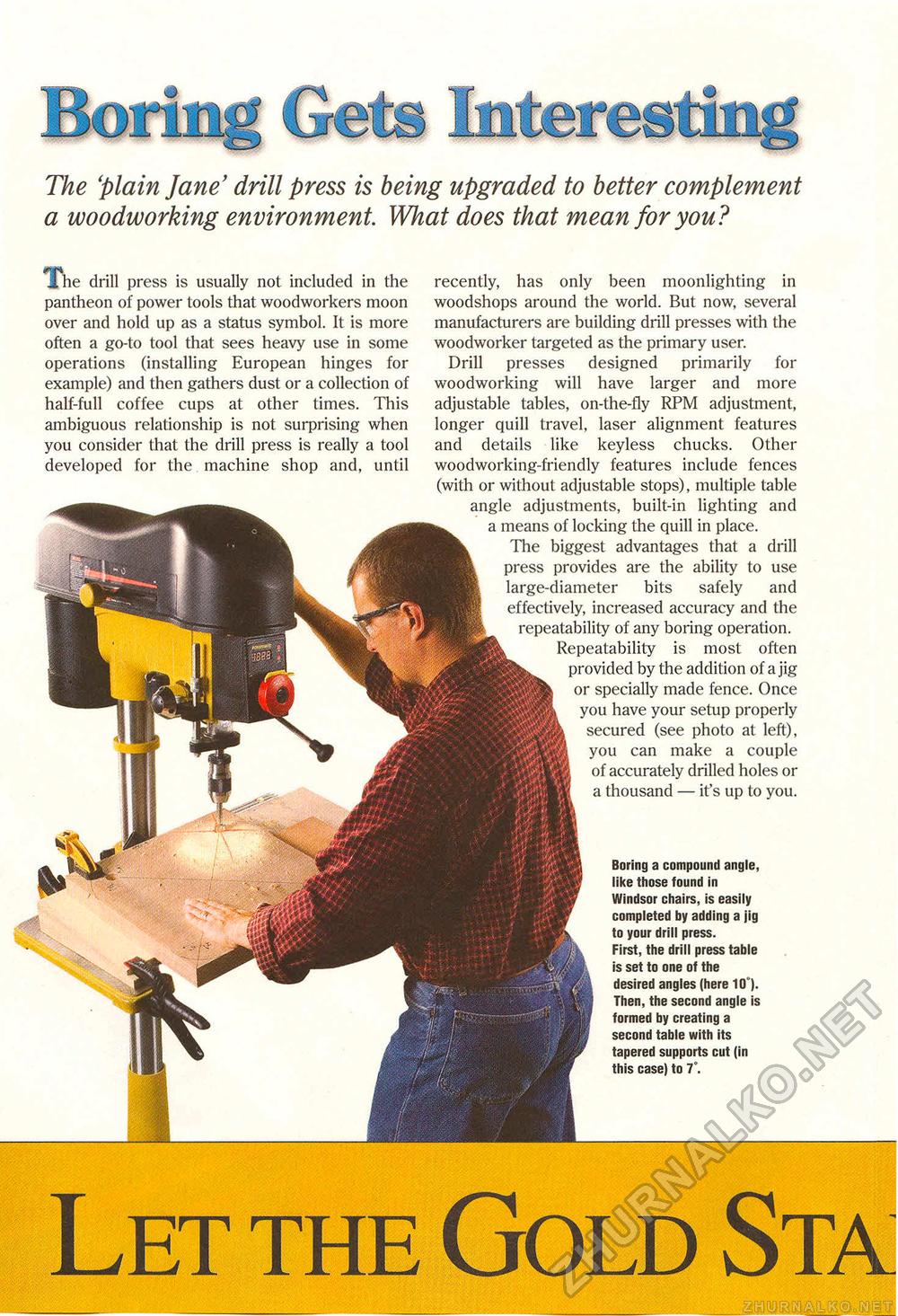

The 'plain Jane' drill press is being upgraded to better complement a woodworking environment. What does that mean for you? Let the IThe drill press is usually not included in the pantheon of power tools that woodworkers moon over and hold up as a status symbol. It is more often a go-to tool that sees heavy use in some operations (installing European hinges for example) and then gathers dust or a collection of half-full coffee cups at other times. This ambiguous relationship is not surprising when you consider that the drill press is really a tool developed for the machine shop and, until recently, has only been moonlighting in woodshops around the world. But now, several manufacturers are building drill presses with the woodworker targeted as the primary user. Drill presses designed primarily for woodworking will have larger and more adjustable tables, on-the-fly RPM adjustment, longer quill travel, laser alignment features and details like keyless chucks. Other woodworking-friendly features include fences (with or without adjustable stops), multiple table gle adjustments, built-in lighting and a means of locking the quill in place. The biggest advantages that a drill press provides are the ability to use large-diameter bits safely and effectively, increased accuracy and the repeatability of any boring operation. Repeatability is most often provided by the addition of a jig or specially made fence. Once you have your setup properly secured (see photo at left), you can make a couple of accurately drilled holes or a thousand — it's up to you. Boring a compound angle, like those found in Windsor chairs, is easily completed by adding a jig to your drill press. First, the drill press table is set to one of the desired angles (here 10°). Then, the second angle is formed by creating a second table with its tapered supports cut (in this case) to 7°. |