Woodworker's Journal 2008-32-2, страница 54

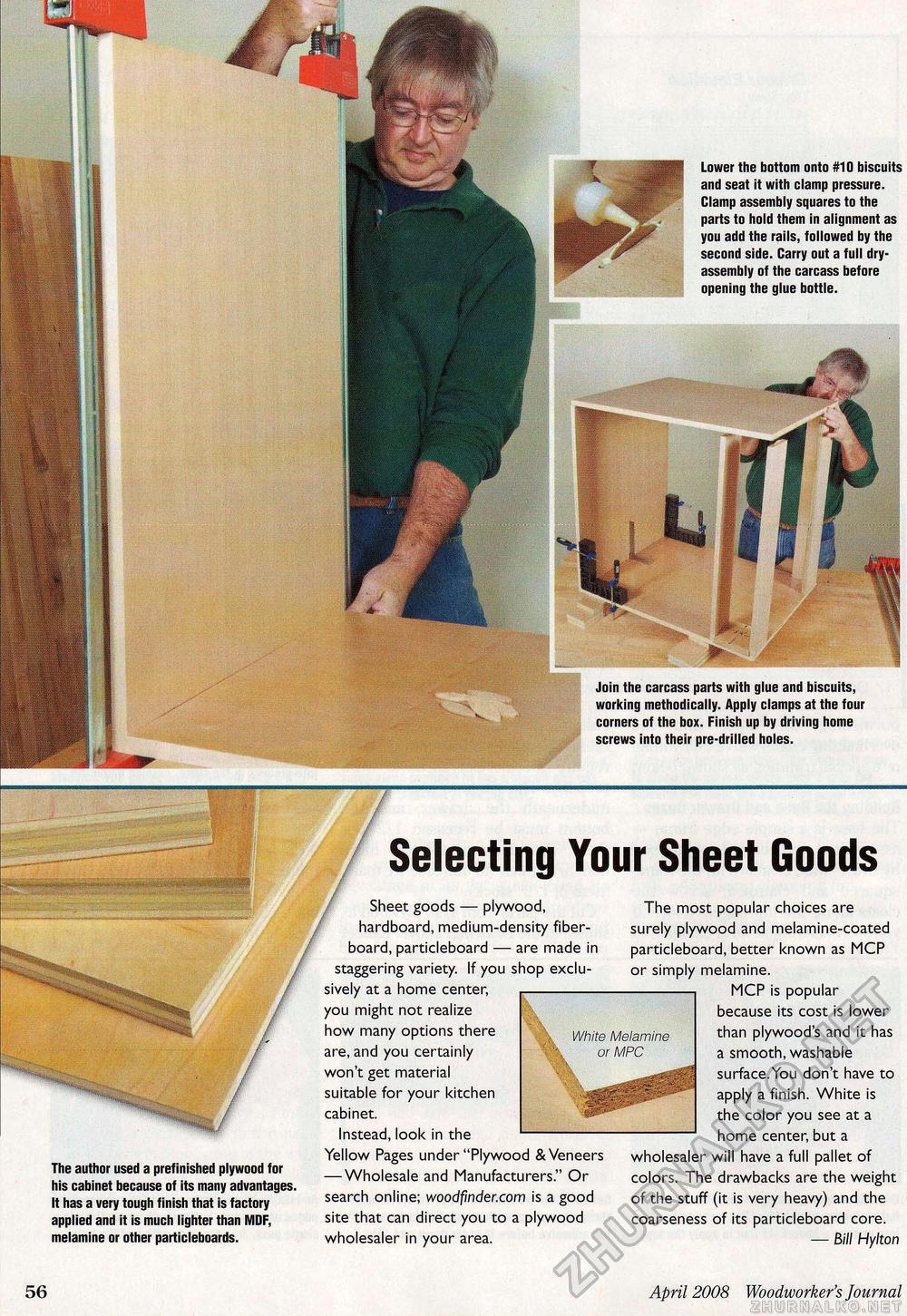

Join the carcass parts with glue and biscuits, working methodically. Apply clamps at the four corners of the box. Finish up by driving home screws into their pre-drilled holes. Lower the bottom onto #10 biscuits and seat it with clamp pressure. Clamp assembly squares to the parts to hold them in alignment as you add the rails, followed by the second side. Carry out a full dry-assembly of the carcass before opening the glue bottle. The author used a prefinished plywood for his cabinet because of its many advantages. It has a very tough finish that is factory applied and it is much lighter than MDF, melamine or other particleboards. Selecting Your Sheet Goods Sheet goods — plywood, hardboard, medium-density fiber-board, particleboard — are made in staggering variety. If you shop exclusively at a home center, you might not realize how many options there are, and you certainly won't get material suitable for your kitchen cabinet. Instead, look in the Yellow Pages under "Plywood & Veneers — Wholesale and Manufacturers." Or search online; woodfinder.com is a good site that can direct you to a plywood wholesaler in your area. The most popular choices are surely plywood and melamine-coated particleboard, better known as MCP or simply melamine. MCP is popular because its cost is lower than plywood's and it has a smooth, washable surface.You don't have to apply a finish. White is the color you see at a home center, but a wholesaler will have a full pallet of colors. The drawbacks are the weight of the stuff (it is very heavy) and the coarseness of its particleboard core. — Bill Hylton 56 April 2008 Woodworker's Journal |