Woodworker's Journal 2008-32-4, страница 26

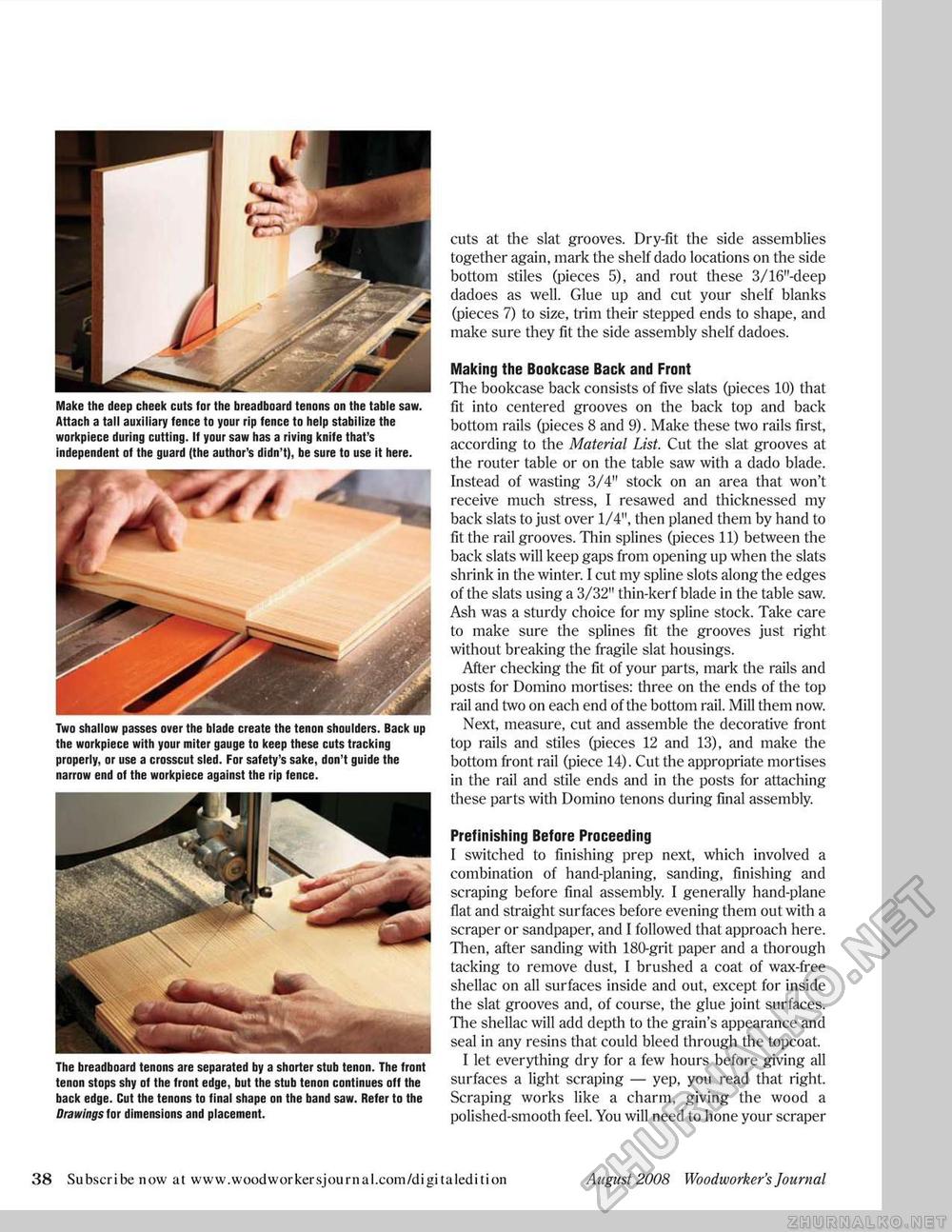

Make the deep cheek cuts for the breadboard tenons on the table saw. Attach a tall auxiliary fence to your rip fence to help stabilize the workpiece during cutting. If your saw has a riving knife that's independent of the guard (the author's didn't), be sure to use it here. The breadboard tenons are separated by a shorter stub tenon. The front tenon stops shy of the front edge, but the stub tenon continues off the back edge. Cut the tenons to final shape on the band saw. Refer to the Drawings for dimensions and placement. cuts at the slat grooves. Dry-fit the side assemblies together again, mark the shelf dado locations on the side bottom stiles (pieces 5), and rout these 3/16"-deep dadoes as well. Glue up and cut your shelf blanks (pieces 7) to size, trim their stepped ends to shape, and make sure they fit the side assembly shelf dadoes. Making the Bookcase Back and Front The bookcase back consists of five slats (pieces 10) that fit into centered grooves on the back top and back bottom rails (pieces 8 and 9). Make these two rails first, according to the Material List. Cut the slat grooves at the router table or on the table saw with a dado blade. Instead of wasting 3/4" stock on an area that won't receive much stress, I resawed and thicknessed my back slats to just over 1/4", then planed them by hand to fit the rail grooves. Thin splines (pieces 11) between the back slats will keep gaps from opening up when the slats shrink in the winter. I cut my spline slots along the edges of the slats using a 3/32" thin-kerf blade in the table saw. Ash was a sturdy choice for my spline stock. Take care to make sure the splines fit the grooves just right without breaking the fragile slat housings. After checking the fit of your parts, mark the rails and posts for Domino mortises: three on the ends of the top rail and two on each end of the bottom rail. Mill them now. Next, measure, cut and assemble the decorative front top rails and stiles (pieces 12 and 13), and make the bottom front rail (piece 14). Cut the appropriate mortises in the rail and stile ends and in the posts for attaching these parts with Domino tenons during final assembly. Prefinishing Before Proceeding I switched to finishing prep next, which involved a combination of hand-planing, sanding, finishing and scraping before final assembly. I generally hand-plane flat and straight surfaces before evening them out with a scraper or sandpaper, and I followed that approach here. Then, after sanding with 180-grit paper and a thorough tacking to remove dust, I brushed a coat of wax-free shellac on all surfaces inside and out, except for inside the slat grooves and, of course, the glue joint surfaces. The shellac will add depth to the grain's appearance and seal in any resins that could bleed through the topcoat. I let everything dry for a few hours before giving all surfaces a light scraping — yep, you read that right. Scraping works like a charm, giving the wood a polished-smooth feel. You will need to hone your scraper Two shallow passes over the blade create the tenon shoulders. Back up the workpiece with your miter gauge to keep these cuts tracking properly, or use a crosscut sled. For safety's sake, don't guide the narrow end of the workpiece against the rip fence. 38 Subscribe now at www.woodworkersjournal.com/digitaledition August 2008 Woodworker's Journal |