Woodworker's Journal 2008-32-4, страница 29

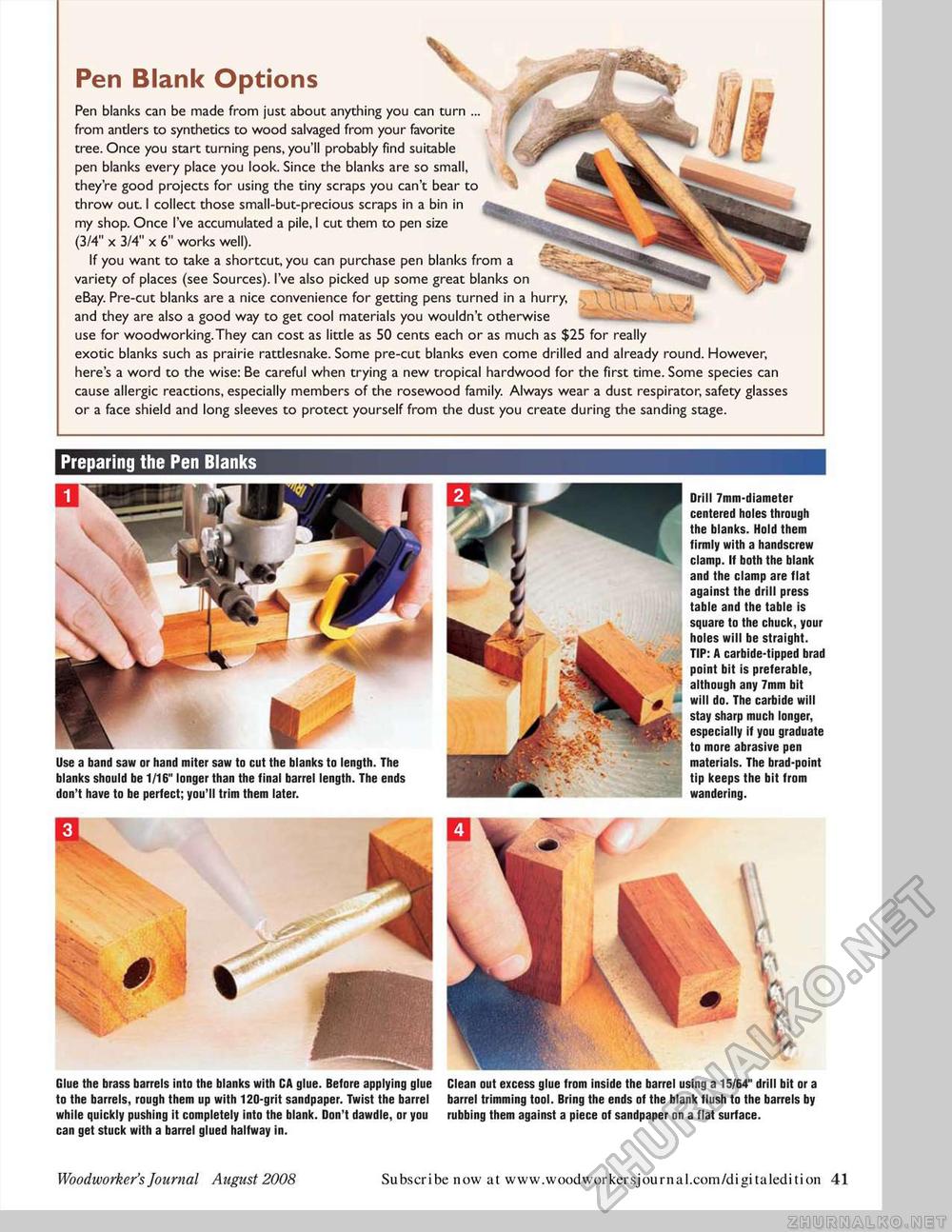

Pen Blank Options Pen blanks can be made from just about anything you can turn ... from antlers to synthetics to wood salvaged from your favorite tree. Once you start turning pens, you'll probably find suitable pen blanks every place you look. Since the blanks are so small, they're good projects for using the tiny scraps you can't bear to throw out I collect those small-but-precious scraps in a bin in my shop. Once I've accumulated a pile, I cut them to pen size (3/4" x 3/4" x 6" works well). If you want to take a shortcut, you can purchase pen blanks from a variety of places (see Sources). I've also picked up some great blanks on eBay. Pre-cut blanks are a nice convenience for getting pens turned in a hurry, and they are also a good way to get cool materials you wouldn't otherwise use for woodworking.They can cost as little as 50 cents each or as much as $25 for really exotic blanks such as prairie rattlesnake. Some pre-cut blanks even come drilled and already round. However, here's a word to the wise: Be careful when trying a new tropical hardwood for the first time. Some species can cause allergic reactions, especially members of the rosewood family. Always wear a dust respirator, safety glasses or a face shield and long sleeves to protect yourself from the dust you create during the sanding stage. Preparing the Pen Blanks Glue the brass barrels into the blanks with CA glue. Betore applying glue Clean out excess glue from inside the barrel using a 15/64" drill bit or a to the barrels, rough them up with 120-grit sandpaper. Twist the barrel barrel trimming tool. Bring the ends of the blank (lush to the barrels by while quickly pushing it completely into the blank. Don't dawdle, or you rubbing them against a piece of sandpaper on a flat surface, can get stuck with a barrel glued halfway in. Drill 7mm-diameter centered holes through the blanks. Hold them firmly with a handscrew clamp. If both the blank and the clamp are flat against the drill press table and the table is square to the chuck, your holes will be straight. TIP: A carbide-tipped brad point bit is preferable, although any 7mm bit will do. The carbide will stay sharp much longer, especially if you graduate to more abrasive pen materials. The brad-point tip keeps the bit from wandering. Use a band saw or hand miter saw to cut the blanks to length. The blanks should be 1/16" longer than the final barrel length. The ends don't have to be perfect; you'll trim them later. Woodworker's Journal August 2008 Subscr ibe now at www.woodworkersjournal.com/digitaledition 79 |