Popular Woodworking 2003-11 № 137, страница 51

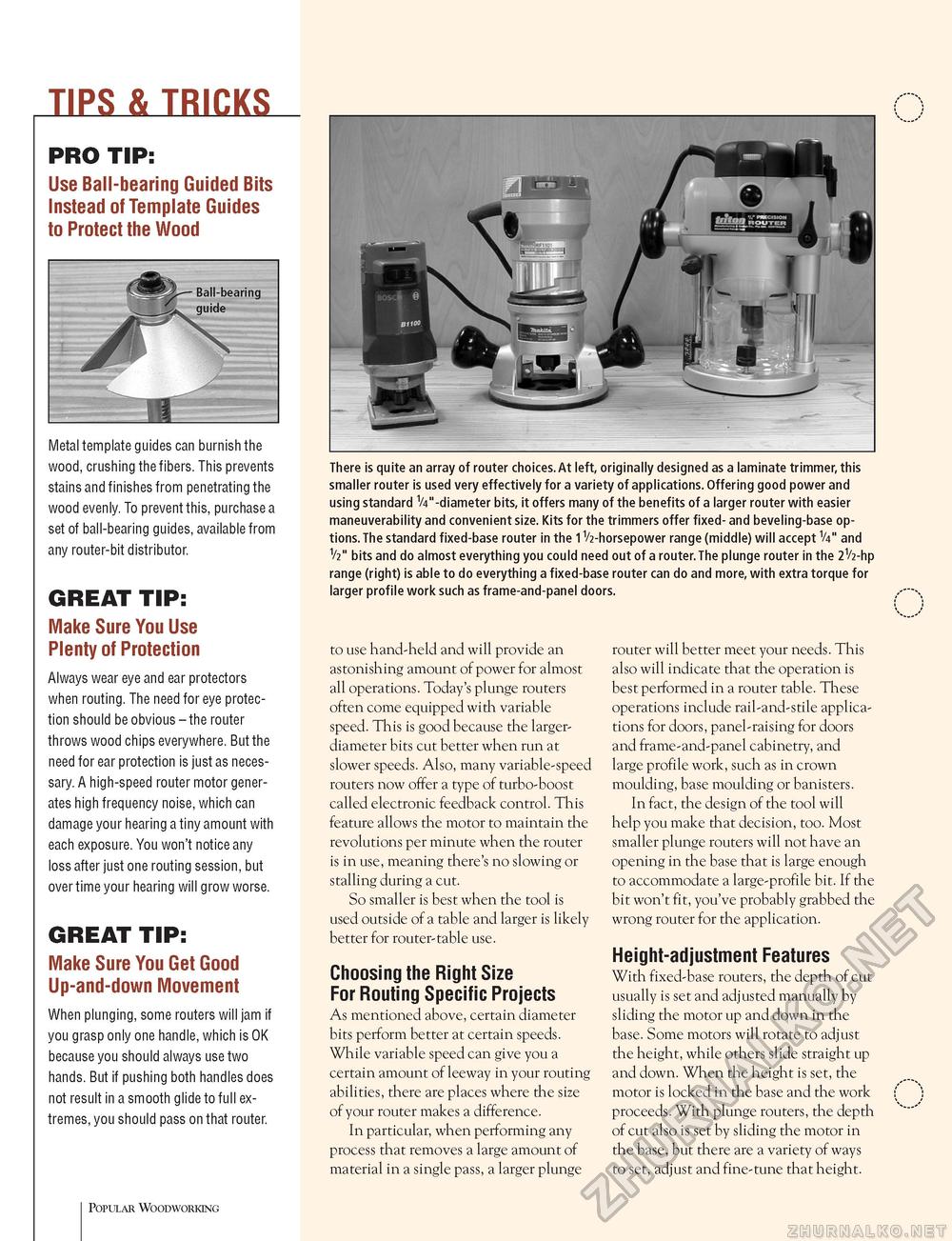

TIPS & TRICKS PRO TIP: Use Ball-bearing Guided Bits Instead of Template Guides to Protect the Wood Metal template guides can burnish the wood, crushing the fibers. This prevents stains and finishes from penetrating the wood evenly. To prevent this, purchase a set of ball-bearing guides, available from any router-bit distributor. GREAT TIP: Make Sure You Use Plenty of Protection Always wear eye and ear protectors when routing. The need for eye protection should be obvious - the router throws wood chips everywhere. But the need for ear protection is just as necessary. A high-speed router motor generates high frequency noise, which can damage your hearing a tiny amount with each exposure. You won't notice any loss after just one routing session, but over time your hearing will grow worse. GREAT TIP: Make Sure You Get Good Up-and-down Movement When plunging, some routers will jam if you grasp only one handle, which is OK because you should always use two hands. But if pushing both handles does not result in a smooth glide to full extremes, you should pass on that router. There is quite an array of router choices. At left, originally designed as a laminate trimmer, this smaller router is used very effectively for a variety of applications. Offering good power and using standard 1/4"-diameter bits, it offers many of the benefits of a larger router with easier maneuverability and convenient size. Kits for the trimmers offer fixed- and beveling-base options. The standard fixed-base router in the 11/2-horsepower range (middle) will accept V4" and V2" bits and do almost everything you could need out of a router. The plunge router in the 21/2-hp range (right) is able to do everything a fixed-base router can do and more, with extra torque for larger profile work such as frame-and-panel doors. to use hand-held and will provide an astonishing amount of power for almost all operations. Today's plunge routers often come equipped with variable speed. This is good because the larger-diameter bits cut better when run at slower speeds. Also, many variable-speed routers now offer a type of turbo-boost called electronic feedback control. This feature allows the motor to maintain the revolutions per minute when the router is in use, meaning there's no slowing or stalling during a cut. So smaller is best when the tool is used outside of a table and larger is likely better for router-table use. Choosing the Right Size For Routing Specific Projects As mentioned above, certain diameter bits perform better at certain speeds. While variable speed can give you a certain amount of leeway in your routing abilities, there are places where the size of your router makes a difference. In particular, when performing any process that removes a large amount of material in a single pass, a larger plunge router will better meet your needs. This also will indicate that the operation is best performed in a router table. These operations include rail-and-stile applications for doors, panel-raising for doors and frame-and-panel cabinetry, and large profile work, such as in crown moulding, base moulding or banisters. In fact, the design of the tool will help you make that decision, too. Most smaller plunge routers will not have an opening in the base that is large enough to accommodate a large-profile bit. If the bit won't fit, you've probably grabbed the wrong router for the application. Height-adjustment Features With fixed-base routers, the depth of cut usually is set and adjusted manually by sliding the motor up and down in the base. Some motors will rotate to adjust the height, while others slide straight up and down. When the height is set, the motor is locked in the base and the work proceeds. With plunge routers, the depth of cut also is set by sliding the motor in the base, but there are a variety of ways to set, adjust and fine-tune that height. Popular Woodworking |