Popular Woodworking 2003-11 № 137, страница 52

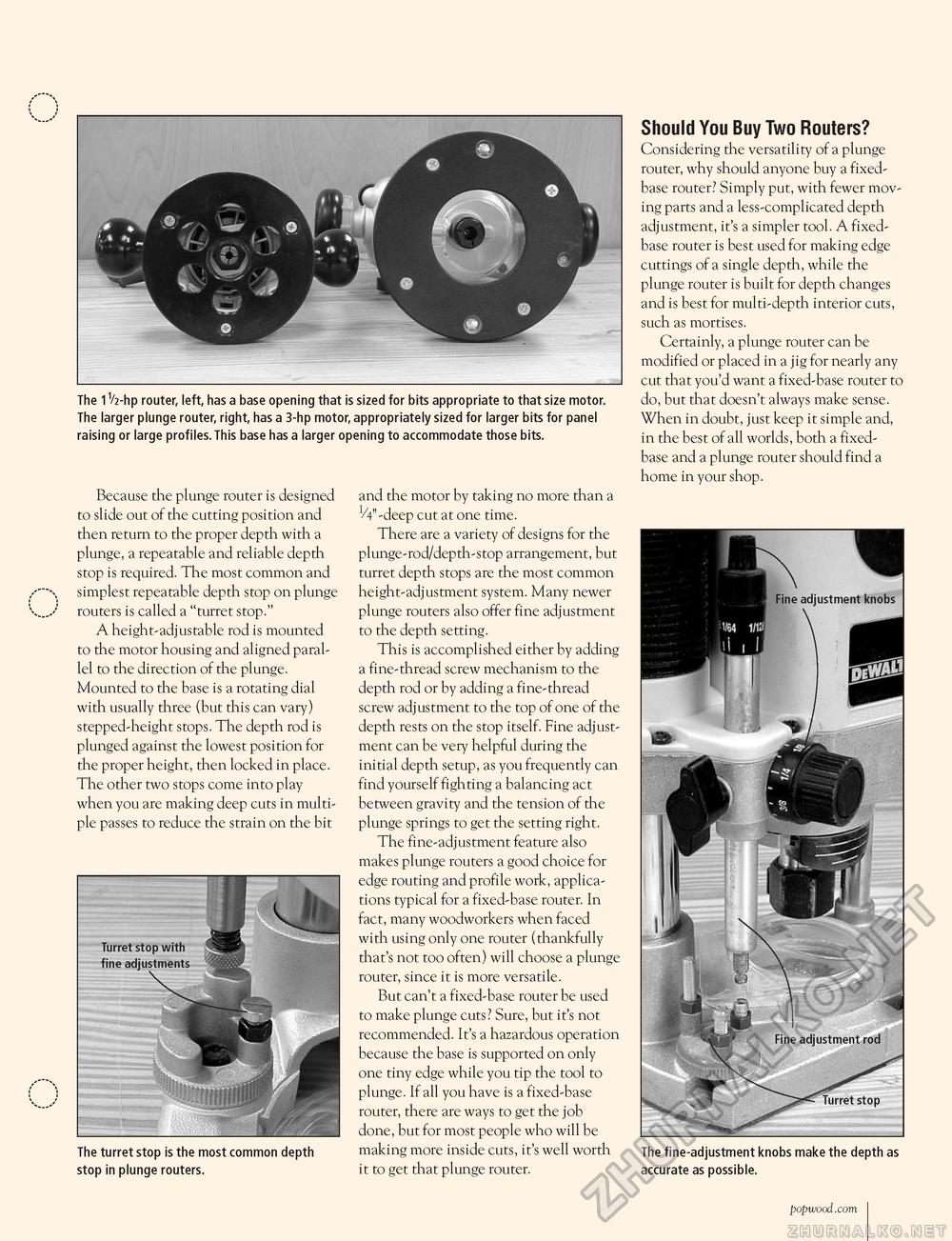

The 11/2-hp router, left, has a base opening that is sized for bits appropriate to that size motor. The larger plunge router, right, has a 3-hp motor, appropriately sized for larger bits for panel raising or large profiles. This base has a larger opening to accommodate those bits. Because the plunge router is designed to slide out of the cutting position and then return to the proper depth with a plunge, a repeatable and reliable depth stop is required. The most common and simplest repeatable depth stop on plunge routers is called a "turret stop." A height-adjustable rod is mounted to the motor housing and aligned parallel to the direction of the plunge. Mounted to the base is a rotating dial with usually three (but this can vary) stepped-height stops. The depth rod is plunged against the lowest position for the proper height, then locked in place. The other two stops come into play when you are making deep cuts in multiple passes to reduce the strain on the bit The turret stop is the most common depth stop in plunge routers. and the motor by taking no more than a 1/4"-deep cut at one time. There are a variety of designs for the plunge-rod/depth-stop arrangement, but turret depth stops are the most common height-adjustment system. Many newer plunge routers also offer fine adjustment to the depth setting. This is accomplished either by adding a fine-thread screw mechanism to the depth rod or by adding a fine-thread screw adjustment to the top of one of the depth rests on the stop itself. Fine adjustment can be very helpful during the initial depth setup, as you frequently can find yourself fighting a balancing act between gravity and the tension of the plunge springs to get the setting right. The fine-adjustment feature also makes plunge routers a good choice for edge routing and profile work, applications typical for a fixed-base router. In fact, many woodworkers when faced with using only one router (thankfully that's not too often) will choose a plunge router, since it is more versatile. But can't a fixed-base router be used to make plunge cuts? Sure, but it's not recommended. It's a hazardous operation because the base is supported on only one tiny edge while you tip the tool to plunge. If all you have is a fixed-base router, there are ways to get the job done, but for most people who will be making more inside cuts, it's well worth it to get that plunge router. Should You Buy Two Routers? Considering the versatility of a plunge router, why should anyone buy a fixed-base router? Simply put, with fewer moving parts and a less-complicated depth adjustment, it's a simpler tool. A fixed-base router is best used for making edge cuttings of a single depth, while the plunge router is built for depth changes and is best for multi-depth interior cuts, such as mortises. Certainly, a plunge router can be modified or placed in a jig for nearly any cut that you'd want a fixed-base router to do, but that doesn't always make sense. When in doubt, just keep it simple and, in the best of all worlds, both a fixed-base and a plunge router should find a home in your shop. The fine-adjustment knobs make the depth as accurate as possible. popwood.com 52 |