Popular Woodworking 2005-04 № 147, страница 47

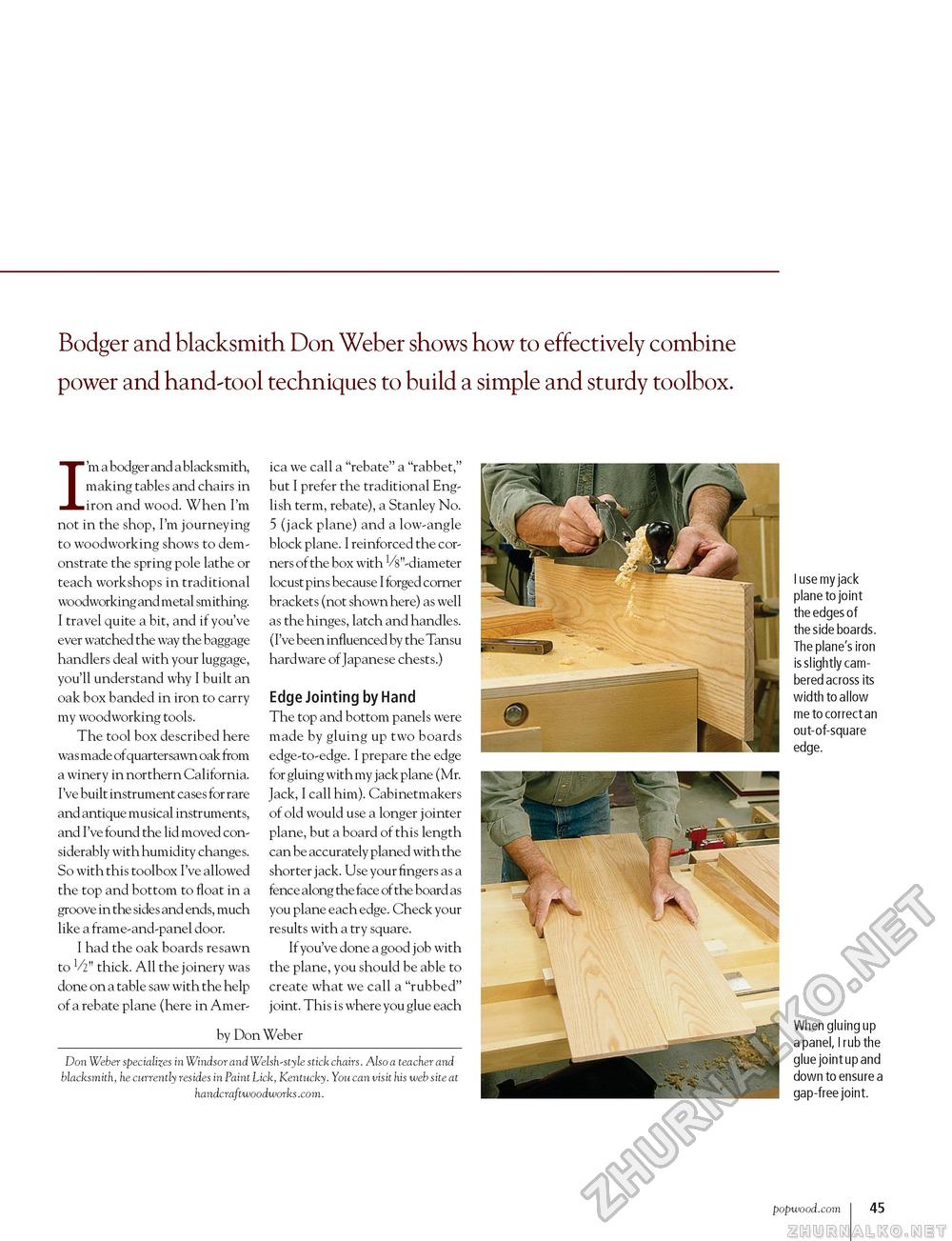

Bodger and blacksmith Don Weber shows how to effectively combine power and hand-tool techniques to build a simple and sturdy toolbox. I'm a bodger and a blacksmith, making tables and chairs in iron and wood. When I'm not in the shop, I'm journeying to woodworking shows to demonstrate the spring pole lathe or teach workshops in traditional woodworking and metal smithing. I travel quite a bit, and if you've ever watched the way the baggage handlers deal with your luggage, you'll understand why I built an oak box banded in iron to carry my woodworking tools. The tool box described here was made of quartersawn oak from a winery in northern California. I've built instrument cases for rare and antique musical instruments, and I've found the lid moved considerably with humidity changes. So with this toolbox I've allowed the top and bottom to float in a groove in the sides and ends, much like a frame-and-panel door. I had the oak boards resawn to V2" thick. All the joinery was done on a table saw with the help of a rebate plane (here in Amer ica we call a "rebate" a "rabbet," but I prefer the traditional English term, rebate), a Stanley No. 5 (jack plane) and a low-angle block plane. I reinforced the corners of the box with Vs'-diameter locust pins because I forged corner brackets (not shown here) as well as the hinges, latch and handles. (I've been influenced by the Tansu hardware of Japanese chests.) Edge Jointing by Hand The top and bottom panels were made by gluing up two boards edge-to-edge. I prepare the edge for gluing with my jack plane (Mr. Jack, I call him). Cabinetmakers of old would use a longer jointer plane, but a board of this length can be accurately planed with the shorter jack. Use your fingers as a fence along the face of the board as you plane each edge. Check your results with a try square. If you've done a good job with the plane, you should be able to create what we call a "rubbed" joint. This is where you glue each by Don Weber Don Weber specializes in Windsor and Welsh-style stick chairs. Also a teacher and blacksmith, he currently resides in Paint Lick, Kentucky. You can visit his web site at handcraftwoodworks.com. I use my jack plane to joint the edges of the side boards. The plane's iron is slightly cambered across its width to allow me to correct an out-of-square edge. When gluing up a panel, I rub the glue joint up and down to ensure a gap-free joint. popwood.com 45 |