Popular Woodworking 2005-06 № 148, страница 42

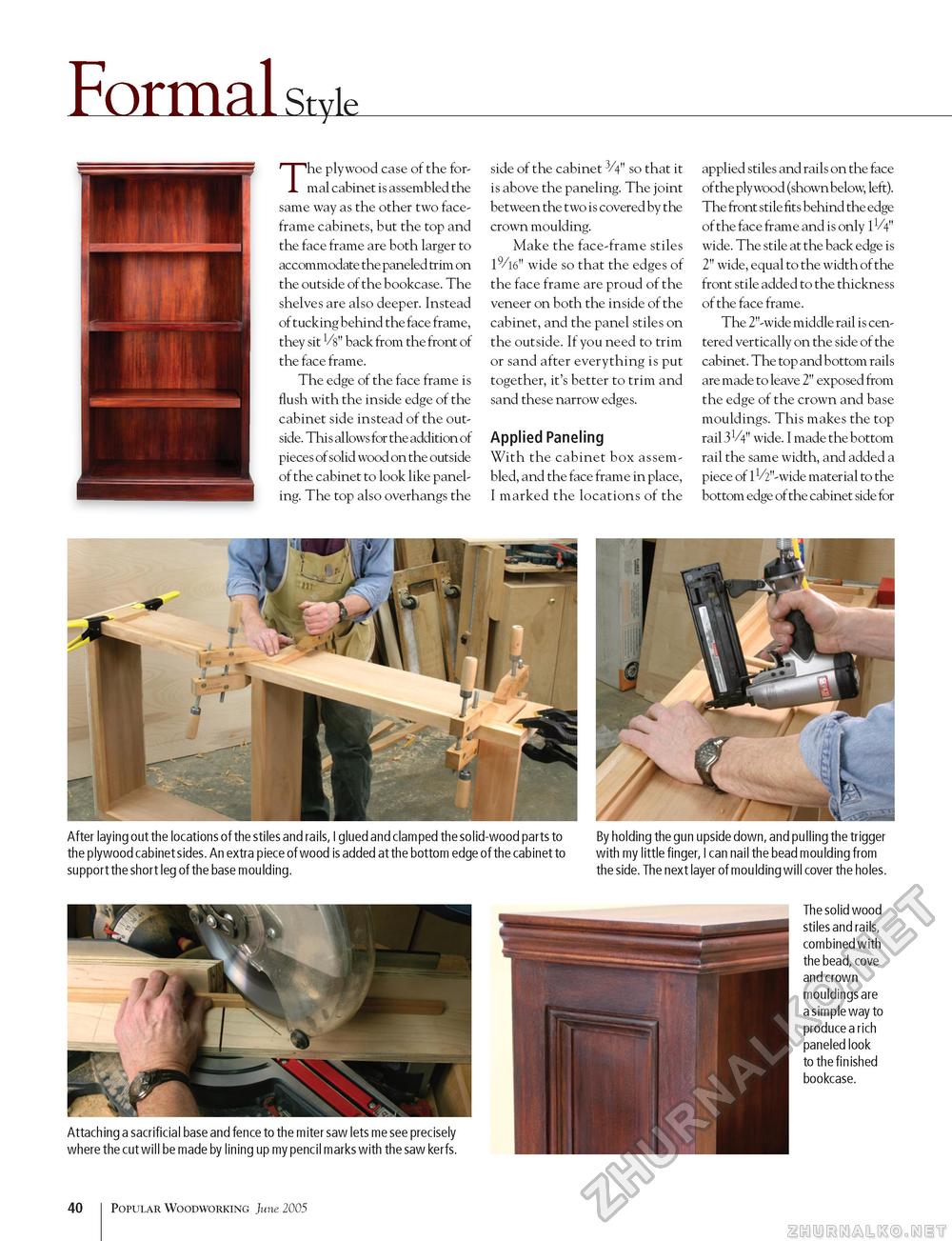

Formal style The plywood case of the formal cabinet is assembled the same way as the other two face-frame cabinets, but the top and the face frame are both larger to accommodate the paneled trim on the outside of the bookcase. The shelves are also deeper. Instead of tucking behind the face frame, they sit Vs" back from the front of the face frame. The edge of the face frame is flush with the inside edge of the cabinet side instead of the outside. This allows for the addition of pieces of solid wood on the outside of the cabinet to look like paneling. The top also overhangs the side of the cabinet 3/4" so that it is above the paneling. The joint between the two is covered by the crown moulding. Make the face-frame stiles 19/l6" wide so that the edges of the face frame are proud of the veneer on both the inside of the cabinet, and the panel stiles on the outside. If you need to trim or sand after everything is put together, it's better to trim and sand these narrow edges. Applied Paneling With the cabinet box assembled, and the face frame in place, I marked the locations of the applied stiles and rails on the face of the plywood (shown below, left). The front stile fits behind the edge of the face frame and is only 1V4" wide. The stile at the back edge is 2" wide, equal to the width of the front stile added to the thickness of the face frame. The 2"-wide middle rail is centered vertically on the side of the cabinet. The top and bottom rails are made to leave 2" exposed from the edge of the crown and base mouldings. This makes the top rail 3V4" wide. I made the bottom rail the same width, and added a piece of lV2"-wide material to the bottom edge of the cabinet side for After laying out the locations of the stiles and rails, I glued and clamped the solid-wood parts to the plywood cabinet sides. An extra piece of wood is added at the bottom edge of the cabinet to support the short leg of the base moulding. By holding the gun upside down, and pulling the trigger with my little finger, I can nail the bead moulding from the side. The next layer of moulding will cover the holes. Attaching a sacrificial base and fence to the miter saw lets me see precisely where the cut will be made by lining up my pencil marks with the saw kerfs. The solid wood stiles and rails, combined with the bead, cove and crown mouldings are a simple way to produce a rich paneled look to the finished bookcase. 40 Popular Woodworking June 2005 |