Popular Woodworking 2006-12 № 159, страница 22

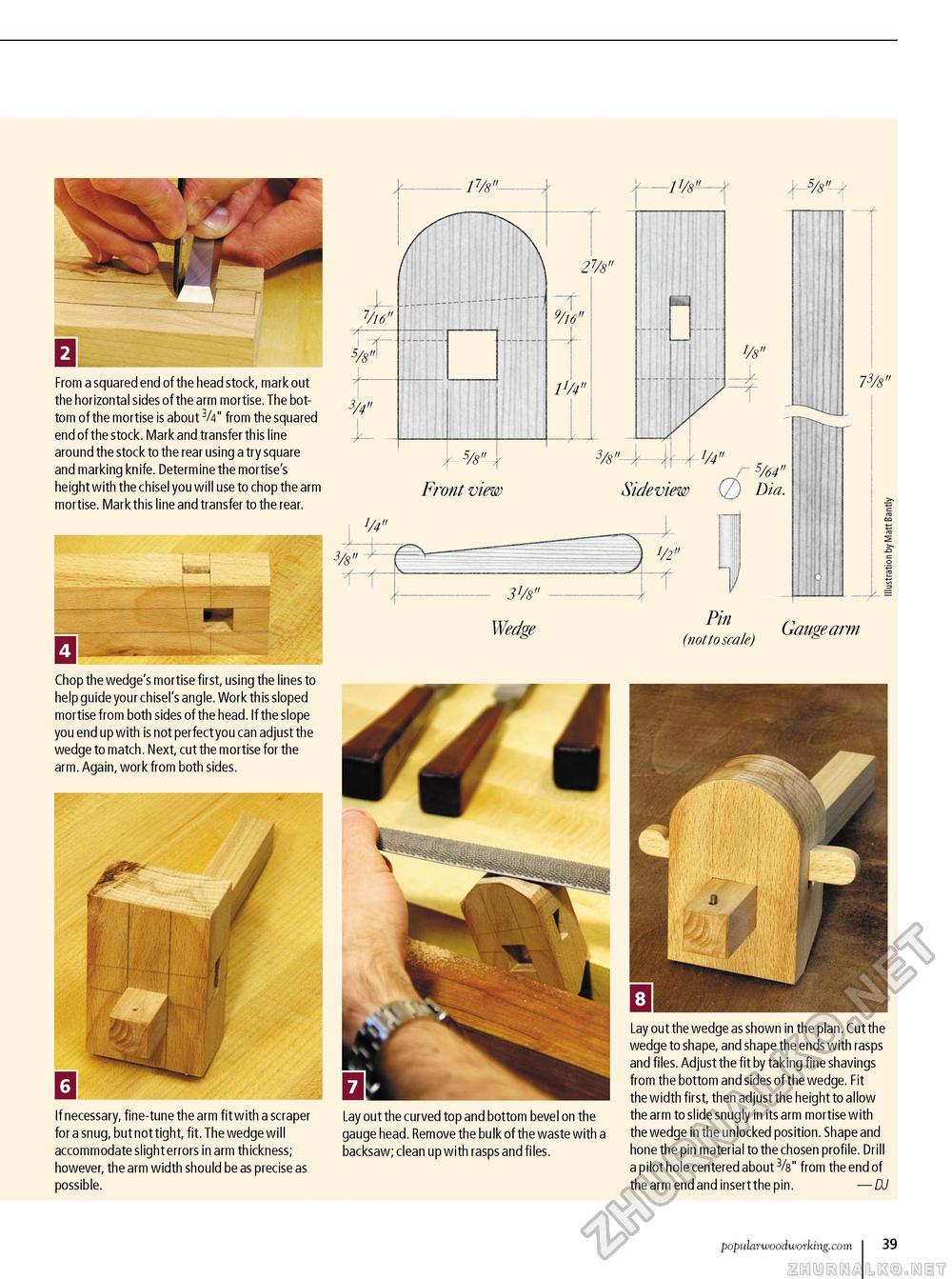

From a squared end of the head stock, mark out the horizontal sides of the arm mortise. The bottom of the mortise is about V4" from the squared end of the stock. Mark and transfer this line around the stock to the rear using a try square and marking knife. Determine the mortise's height with the chisel you will use to chop the arm mortise. Mark this line and transfer to the rear. Vl6" 5/8 3/4" 5/8" Front view lW 2'/8" 9/l6" — lW 3/8" w w Side view <zf 5/64" Dia. a 7 Pin (notto scale) ! Ill Gaugearm Chop the wedge's mortise first, using the lines to help guide your chisel's angle. Work this sloped mortise from both sides of the head. If the slope you end up with is not perfect you can adjust the wedge to match. Next, cut the mortise for the arm. Again, work from both sides. If necessary, fine-tune the arm fit with a scraper for a snug, but not tight, fit. The wedge will accommodate slight errors in arm thickness; however, the arm width should be as precise as possible. Lay out the curved top and bottom bevel on the gauge head. Remove the bulk of the waste with a backsaw; clean up with rasps and files. Lay out the wedge as shown in the plan. Cut the wedge to shape, and shape the ends with rasps and files. Adjust the fit by taking fine shavings from the bottom and sides of the wedge. Fit the width first, then adjust the height to allow the arm to slide snugly in its arm mortise with the wedge in the unlocked position. Shape and hone the pin material to the chosen profile. Drill a pilot hole centered about 3/8" from the end of the arm end and insert the pin. — DJ popularwoodworking.com i 39 |