Popular Woodworking 2007-12 № 166, страница 47

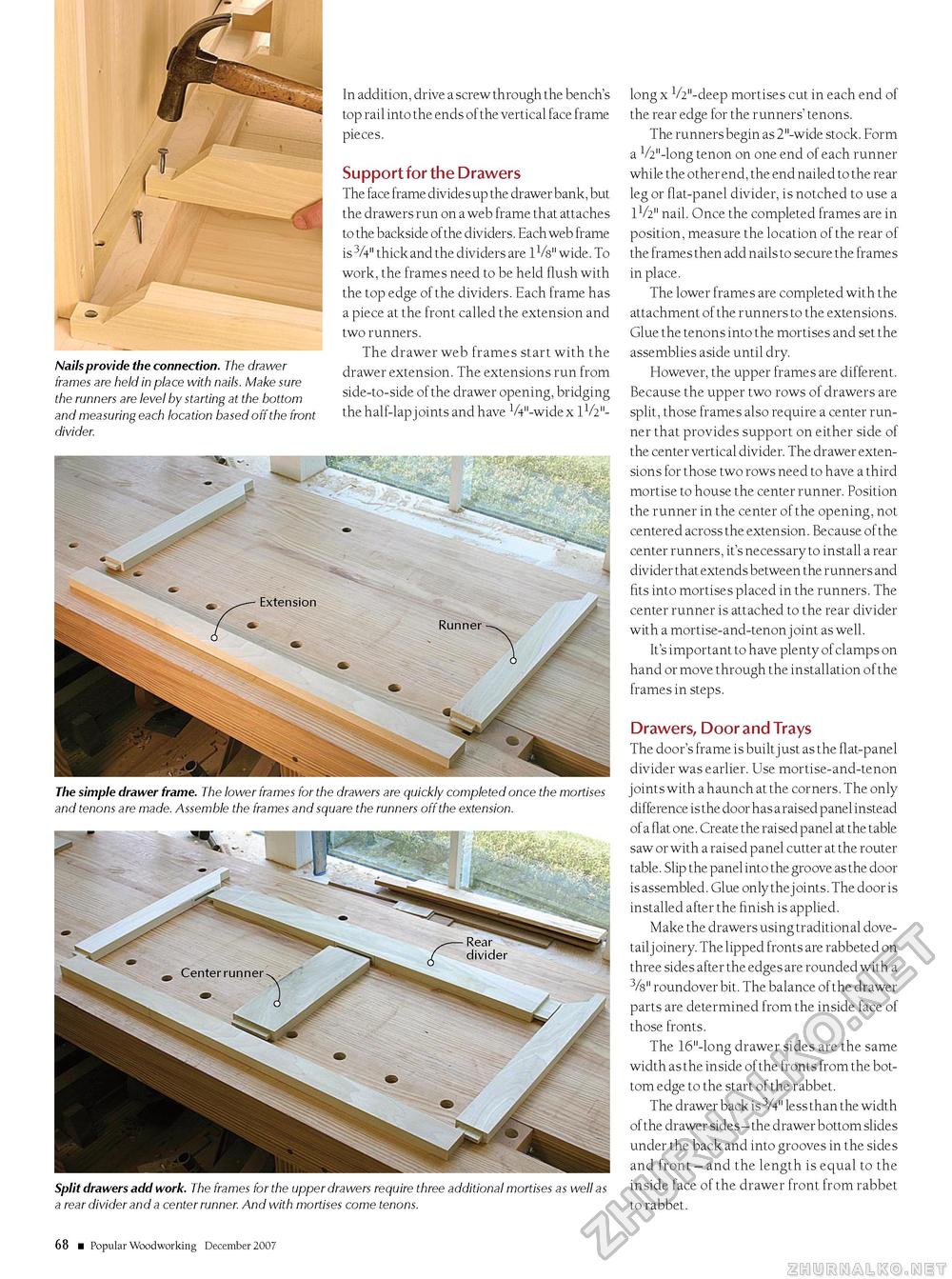

Nails provide the connection. The drawer frames are held in place with nails. Make sure the runners are level by starting at the bottom and measuring each location based off the front divider. In addition, drive a screw through the bench's top rail into the ends of the vertical face frame pieces. Support for the Drawers The face frame divides up the drawer bank, but the drawers run on a web frame that attaches to the backside of the dividers. Each web frame is 3/4" thick and the dividers are 11/8" wide. To work, the frames need to be held flush with the top edge of the dividers. Each frame has a piece at the front called the extension and two runners. The drawer web frames start with the drawer extension. The extensions run from side-to-side of the drawer opening, bridging the half-lap joints and have V4"-wide x 1V2"- long x 1/2"-deep mortises cut in each end of the rear edge for the runners' tenons. The runners begin as 2"-wide stock. Form a 1/2"-long tenon on one end of each runner while the other end, the end nailed to the rear leg or flat-panel divider, is notched to use a 1V2" nail. Once the completed frames are in position, measure the location of the rear of the frames then add nails to secure the frames in place. The lower frames are completed with the attachment of the runners to the extensions. Glue the tenons into the mortises and set the assemblies aside until dry. However, the upper frames are different. Because the upper two rows of drawers are split, those frames also require a center runner that provides support on either side of the center vertical divider. The drawer extensions for those two rows need to have a third mortise to house the center runner. Position the runner in the center of the opening, not centered across the extension. Because of the center runners, it's necessary to install a rear divider that extends between the runners and fits into mortises placed in the runners. The center runner is attached to the rear divider with a mortise-and-tenon joint as well. It's important to have plenty of clamps on hand or move through the installation of the frames in steps. Drawers, Door and Trays The door's frame is built just as the flat-panel divider was earlier. Use mortise-and-tenon joints with a haunch at the corners. The only difference is the door has a raised panel instead of a flat one. Create the raised panel at the table saw or with a raised panel cutter at the router table. Slip the panel into the groove as the door is assembled. Glue only the j oints. The door is installed after the finish is applied. Make the drawers using traditional dovetail j oinery. The lipped fronts are rabbeted on three sides after the edges are rounded with a 3/8" roundover bit. The balance of the drawer parts are determined from the inside face of those fronts. The 16"-long drawer sides are the same width as the inside of the fronts from the bottom edge to the start of the rabbet. The drawer back is 3A" less than the width of the drawer sides - the drawer bottom slides under the back and into grooves in the sides and front - and the length is equal to the inside face of the drawer front from rabbet to rabbet. The simple drawer frame. The lower frames for the drawers are quickly completed once the mortises and tenons are made. Assemble the frames and square the runners off the extension. Split drawers add work. The frames for the upper drawers require three additional mortises as well as a rear divider and a center runner. And with mortises come tenons. 68 ■ Popular Woodworking December 2007 |